Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

If you have your CAM set up to your advantage then a couple of minutes max to code for something like that.Brilliant!! I'm constantly amazed at the speed at which these CNC machines [and I include lathes etc in that] work.

How long did it take to write the control programme file?

Doing the drawing in the first place would be the bit that takes the time but even then probably less than 30 mins for something like that. For something similar to the parts I cut out the last day (pic below) then 4 or 5 mins to draw and about 2 mins to choose the tool paths, do a simulation, post the code and transfer via the network from my desk to the machines computer out in the container.

oops, sorry wrong pic, I meant this one.

Edit again, in fact I reckon it would only have been a couple of minutes to draw them.

.

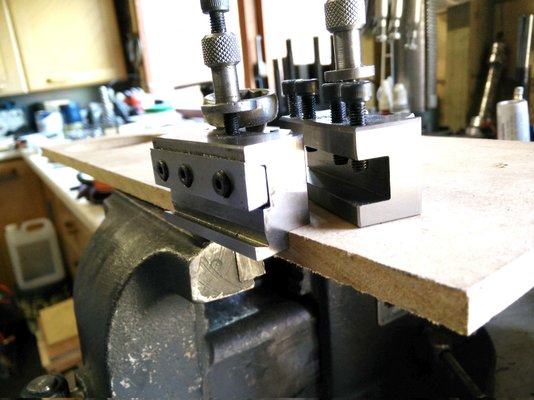

. See if you can see what Dopey had done, from this pic? [the end of the ring spanner is only there to stop the part launching itself to the floor while I was taking the pic

See if you can see what Dopey had done, from this pic? [the end of the ring spanner is only there to stop the part launching itself to the floor while I was taking the pic

. So, it would fit in my correct one on the left above, but being square shank it would 'cobble' a bit. I'll just send off for a blade type to fit in due course.

. So, it would fit in my correct one on the left above, but being square shank it would 'cobble' a bit. I'll just send off for a blade type to fit in due course. ]. In the course of all this swapping round bits, inc tool-post holders, I discovered that the tool-post stud is slightly bent, and here was me thinking my 7/16" tapping was off vertical when I made the handle I posted about earlier

]. In the course of all this swapping round bits, inc tool-post holders, I discovered that the tool-post stud is slightly bent, and here was me thinking my 7/16" tapping was off vertical when I made the handle I posted about earlier  .

. ], but it's for the original type tool clamp.

], but it's for the original type tool clamp.