Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

Sorry to be the bearer of bad news but 1.5mm is the starting point. It’s far from thin.hold that for me (beer)

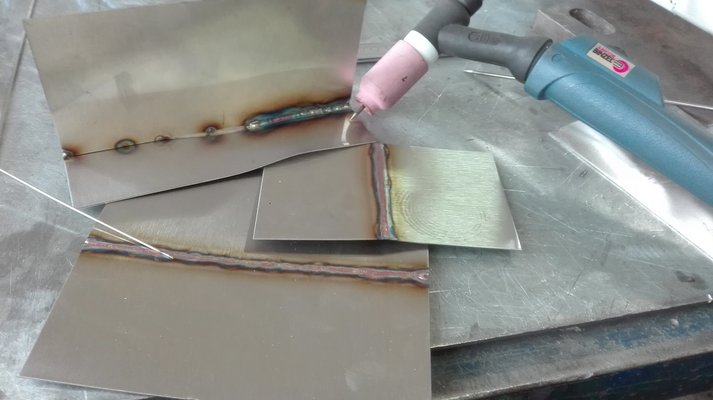

no doubt it can be done with a very tight arc, but tacking it is a pain. especially with aluminum where you need to put pressure on the material with a hand that is holding the filler rod. anyways a 10kg steel block which i used to pull off the heat fallen on the TIG torch cable and its out of cooling. but challenge accepted, ill try to crack it with 1,0-1,2mm MIG wire and 55-60A when i fix he torch or someone else before i go to work. anyways its friday why are we talking about welding

well, it will be friday after another 8 h at work so we can talk...

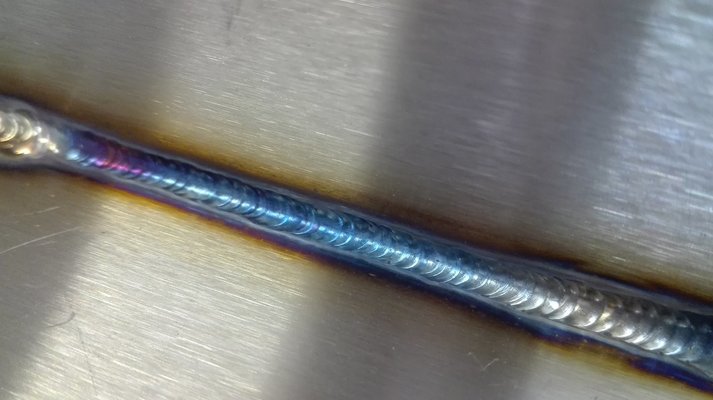

When I do my sessions with people on stainless we start on 1.6 and move down depending on skill and ambition I’ve gotten nice results out of people on 0.7

so i had to stop. but i think it wasnt a bad attempt.

so i had to stop. but i think it wasnt a bad attempt.