Gary Batterbee

New Member

- Messages

- 8

- Location

- Uk

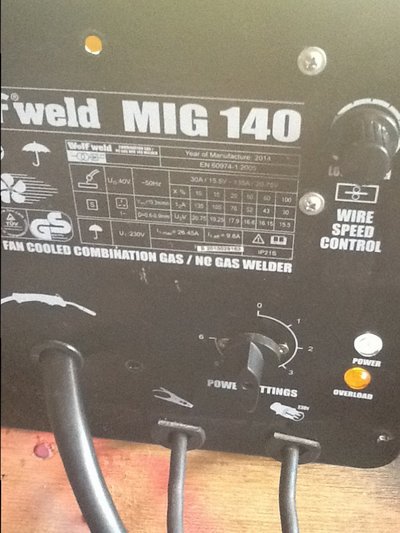

hi I could really use some help with this one! I recently bought this mig, tested it beforehand. Worked ok, brought it home, hooked up new gas but as soon as it's turned on the overload light comes on, the fan runs, gas comes through the torch but the trigger does nothing!,, I've Checked the pc board for damage and the fuse is ok?? Any advice please?, thanks in advance,

Gary

Gary