FjerrFjerrson

Member

- Messages

- 25

So I've had a few days to get set up and have a bit of a mess around with my new Wolf 140 Mig Welder (30A - 135A). Here are my findings, from a newbie's point of view. I did a bit of training on a 3-phase monster at a training centre. Whilst my welder is obviously going to be nowhere near as good as that, the results were (for me) quite satisfactory and pleasing. I bought the welder from Amazon (via the marketplace) for £149.98 and it included quite a good kit of spare parts, wire, a cheap-o mask, brush, and 1 cylinder of CO2 gas and regulator.

Setting up the welder out-of-the-box wasn't too taxing... just a case of adding a few screws to fix on some parts, and snapping on some plastic bits here and there. Notably the power wire did not come with a plug; this is due to the fact the book suggests you can put on a 13A household plug, or a 16/32A big plug. (heh... I really do know my terminology, eh?). If you have seen one of my earlier posts regarding power, you will have seen that I had some problems keeping the machine powered on, but this eventually was due to the abysmal wiring where I live and has now been fixed. I can run the welder at full power on a 13A plug without issue.

Initially I had a problem with a faulty regulator which lead to valve damage (which resulted in a garage full of CO2 and an empty cylinder). After a quick phonecall to UKHS technical support at 3pm one day (I believe they own the Wolf brand now) they had a new cylinder and regulator to me the next morning by Parcelforce. Nice and speedy!

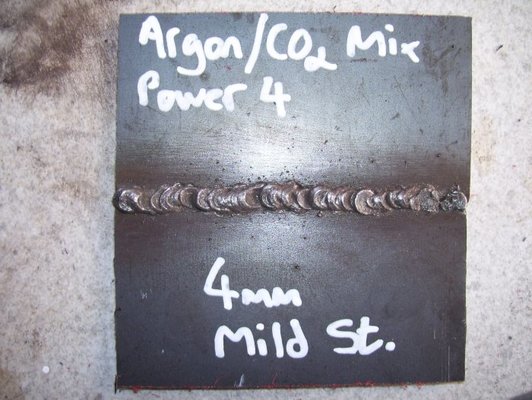

After finally getting all sorted out I was ready to give this machine a whirl. I opted to configure for a Gas-based setup, as I am not familiar with gasless welding. Now that I have tried this, I can confirm that this particular version of the Wolf 140 Mig has a Non-Live torch. You can find the photos below to see how my first runs turned out. The first 3 pictures were bad, but as you will discover reading down this thread, I just didn't have the gas turned on anywhere near enough (DOH!). The final picture is where the gas is now properly on.

The photos are all using 4mm mild steel (it's all I had...) and the numbers i've written on are the power levels (max = 6). The Butt weld was using 4mm mild that I V-Grooved prior to welding. The final photo is one of the attempts after I corrected the "lack of gas" problem mentioned above. It's a tad easier on the eyes, that's for sure!

Setting up the welder out-of-the-box wasn't too taxing... just a case of adding a few screws to fix on some parts, and snapping on some plastic bits here and there. Notably the power wire did not come with a plug; this is due to the fact the book suggests you can put on a 13A household plug, or a 16/32A big plug. (heh... I really do know my terminology, eh?). If you have seen one of my earlier posts regarding power, you will have seen that I had some problems keeping the machine powered on, but this eventually was due to the abysmal wiring where I live and has now been fixed. I can run the welder at full power on a 13A plug without issue.

Initially I had a problem with a faulty regulator which lead to valve damage (which resulted in a garage full of CO2 and an empty cylinder). After a quick phonecall to UKHS technical support at 3pm one day (I believe they own the Wolf brand now) they had a new cylinder and regulator to me the next morning by Parcelforce. Nice and speedy!

After finally getting all sorted out I was ready to give this machine a whirl. I opted to configure for a Gas-based setup, as I am not familiar with gasless welding. Now that I have tried this, I can confirm that this particular version of the Wolf 140 Mig has a Non-Live torch. You can find the photos below to see how my first runs turned out. The first 3 pictures were bad, but as you will discover reading down this thread, I just didn't have the gas turned on anywhere near enough (DOH!). The final picture is where the gas is now properly on.

The photos are all using 4mm mild steel (it's all I had...) and the numbers i've written on are the power levels (max = 6). The Butt weld was using 4mm mild that I V-Grooved prior to welding. The final photo is one of the attempts after I corrected the "lack of gas" problem mentioned above. It's a tad easier on the eyes, that's for sure!

Last edited:

Thanks for the feedback!

Thanks for the feedback! ) and as it turns out, Gas was the problem. Note to self: when the instruction book says "turn on the gas 1 turn" it actually means "turn on the gas 4.5-5 turns".

) and as it turns out, Gas was the problem. Note to self: when the instruction book says "turn on the gas 1 turn" it actually means "turn on the gas 4.5-5 turns".