MiggySmalls

Member

- Messages

- 8

- Location

- Uk

Hi,

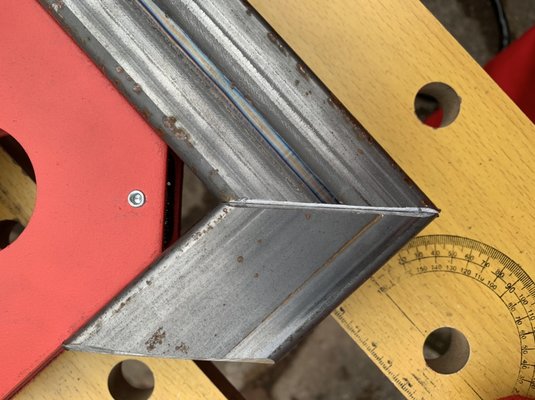

I’m making a stand for my mill out of 50x50x2.5mm mild steel box section. Have tried to weld together a test piece for the top, using a Mig FL-140 from Static Arc with 0.8mm flux core wire (gasless).

One of the welds blew through. I think I slowed down too much there. I welded the outer corner vertically from top to bottom - I wondered if that was asking for trouble.

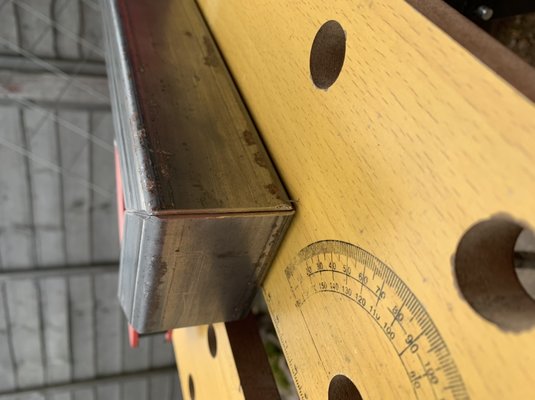

Apart from any thoughts on what I’m doing wrong, I’m curious what you think about the one weld that seems least worst (the one before the shots with the blown out weld). It looks just about okay to me from the outside, but if I look at the other side (inside the box section), should I see the two pieces of section fused together, or is it okay to still have the line between them clearly visible? (See last image)

Hope that makes sense. Simple question phrased badly I think!

Cheers,

Miggy

I’m making a stand for my mill out of 50x50x2.5mm mild steel box section. Have tried to weld together a test piece for the top, using a Mig FL-140 from Static Arc with 0.8mm flux core wire (gasless).

One of the welds blew through. I think I slowed down too much there. I welded the outer corner vertically from top to bottom - I wondered if that was asking for trouble.

Apart from any thoughts on what I’m doing wrong, I’m curious what you think about the one weld that seems least worst (the one before the shots with the blown out weld). It looks just about okay to me from the outside, but if I look at the other side (inside the box section), should I see the two pieces of section fused together, or is it okay to still have the line between them clearly visible? (See last image)

Hope that makes sense. Simple question phrased badly I think!

Cheers,

Miggy

-

CA17CD5C-6B52-46A4-BEB9-16DCF3EEC439.jpeg353.4 KB · Views: 118

CA17CD5C-6B52-46A4-BEB9-16DCF3EEC439.jpeg353.4 KB · Views: 118 -

52003BB3-B978-4598-A9B2-7DCB5C91701A.jpeg276.5 KB · Views: 109

52003BB3-B978-4598-A9B2-7DCB5C91701A.jpeg276.5 KB · Views: 109 -

99F048C7-080E-4656-92C0-B207066C0C10.jpeg282.3 KB · Views: 121

99F048C7-080E-4656-92C0-B207066C0C10.jpeg282.3 KB · Views: 121 -

772E410F-9659-4016-A3CC-F544158EAE61.jpeg235.4 KB · Views: 105

772E410F-9659-4016-A3CC-F544158EAE61.jpeg235.4 KB · Views: 105 -

0CBB9AF8-0933-464E-ADCA-0403E66D959E.jpeg402.1 KB · Views: 114

0CBB9AF8-0933-464E-ADCA-0403E66D959E.jpeg402.1 KB · Views: 114 -

26A3E7A1-8F1C-4888-B39C-42E2BE88E4AB.jpeg374.5 KB · Views: 116

26A3E7A1-8F1C-4888-B39C-42E2BE88E4AB.jpeg374.5 KB · Views: 116 -

CD062200-0294-41FB-9686-1F4B7FB3229F.jpeg288.6 KB · Views: 109

CD062200-0294-41FB-9686-1F4B7FB3229F.jpeg288.6 KB · Views: 109 -

54496479-85DE-43FD-9F12-30D89668127E.jpeg222.7 KB · Views: 114

54496479-85DE-43FD-9F12-30D89668127E.jpeg222.7 KB · Views: 114