You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which grit CBN wheel for sharpening tungsten electrodes

- Thread starter Chris152

- Start date

Agroshield

Member

- Messages

- 6,368

Is there some reason you have gone for CBN? From what little I understand, I thought tungstens were normally sharpened on diamond wheels.

The kind of wheel you need might depend on how good a welder you are. If it is for occasional touch ups and aerospace procedure work, a finer wheel might be better than a beginner dipping the electrode every 1" of travel and needing to re-point a cylinder after cutting off the blob.

The kind of wheel you need might depend on how good a welder you are. If it is for occasional touch ups and aerospace procedure work, a finer wheel might be better than a beginner dipping the electrode every 1" of travel and needing to re-point a cylinder after cutting off the blob.

Just reading around the web tbh, it seems like a lot of people use CBN but I've no idea between that and diamond. It's for my son, he's doing welding and fabrication at college, 3rd year so deffo learning but hopefully getting there.Is there some reason you have gone for CBN? From what little I understand, I thought tungstens were normally sharpened on diamond wheels.

The kind of wheel you need might depend on how good a welder you are. If it is for occasional touch ups and aerospace procedure work, a finer wheel might be better than a beginner dipping the electrode every 1" of travel and needing to re-point a cylinder after cutting off the blob.

A couple of these would be my choice, https://www.aliexpress.com/item/1005004910904702.html Maybe 80 and 180, you can fit 2 one one end of a bench grinder and use one for grinding back to shape and the other for a finer finish. Currently £9 for 2 delivered.

Kram

Member

- Messages

- 8,476

- Location

- Sussex

Horrible messy soft wheels, yes they will do the job but you'll cut trenches innthem quicker than standard alumina wheels which also do the job quite adequately. The problem is if you want a single wheel to do tungstens and that will stay relatively flat for other purposes, neither wheel are a good choice.Green grit (silicon carbide) does the job.

Special wheels are not really required for tungsten, more used for tungsten carbide cutting tools. However the normal alumina wheels are only common in coarse grits 80 or rarely 120.. and will get grooved easily.

Cbn generally cost a bit as china is not mass producing them in the same numbers, compared to diamond wheels, and diamond works just as well for tungstens or carbide, and are available quite cheap, but not nessasarily in the ideal shape/size and price.

For diamond wheels I have used a 600 grit, extremely fine. Theres no issues with it for tungsten, even using the corner to cut a 2.4mm tungsten in two is quick, they all get to a point fast enough. I usually have a 120 or 180 fitted.

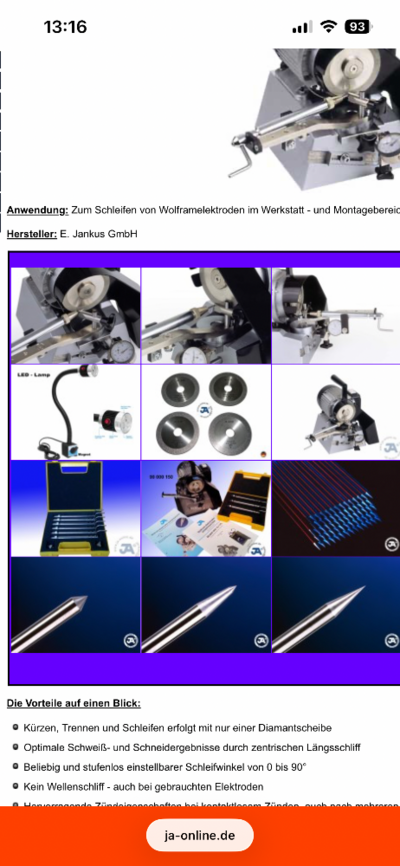

Something like this... There will be others

Theres others, thats likely not the cheapest as I only had a quick look. Cup wheels avoid a hollow grind that you'd get from using the OD of a wheel.

RobCox

Member

- Messages

- 551

- Location

- Cambridge, UK

Either will work. I rough sharpen on an oxide wheel then polish the cone on an old CBN wheel which removes all the grinding marks and leaves it shiny. I'm not very good at TIG so the electrode gets dipped frequently.is CBN or Diamond better for sharpening tungsten?

The biggest difference you'll find is the cost. Diamond wheels are available for £20 ish from the far east. CBN on the other hand will set you back prob 5x that. Beware the aliexpress etc listings for "CBN". They're prob electrocoated diamond at the prices offered.

Kram

Member

- Messages

- 8,476

- Location

- Sussex

If your sharpening along the length rather than sideways, you'll not notice any difference between 60 grit and 600.

Some say sharpening along the side will give issues, and a finer grit will surely reduce that, but cant say I have noticed either way.

Some say sharpening along the side will give issues, and a finer grit will surely reduce that, but cant say I have noticed either way.

They were a fiver on amazon when I got mine, I'd expect 5-15 from ebay shipped from china. Not had any problems they were all good, I have a few.The biggest difference you'll find is the cost. Diamond wheels are available for £20 ish from the far east

So, something like this for the bench grinder? Or are the electroplated discs more stable/ better?I use 100 grit diamond

P150 Diameter 150mm Flat Diamond Abrasive Grinding Wheel for Alloy Steel Ceramic Glass Jade CBN Grinding(150mmx20mmx32mmx4mm) : Amazon.co.uk: Business, Industry & Science

P150 Diameter 150mm Flat Diamond Abrasive Grinding Wheel for Alloy Steel Ceramic Glass Jade CBN Grinding(150mmx20mmx32mmx4mm) : Amazon.co.uk: Business, Industry & Science

www.amazon.co.uk

As Kram says - far too soft. Grit and dust everywhere and furrows in no time!Green grit (silicon carbide) does the job.

Linishers are pretty good or a diamond wheel.

BrokenBiker

Member

- Messages

- 12,922

- Location

- Newport, South Wales

My father has a 320 grit CBN wheel for sharpening his chisels, I've used it for Tungstens and worked fine, didn't leave any marks on the wheel. Little bit slower than my diamond disc in the angle grinder but about the same as a normal bench grinder with a 36 grit wheel

I use diamond like these.A couple of these would be my choice, https://www.aliexpress.com/item/1005004910904702.html Maybe 80 and 180, you can fit 2 one one end of a bench grinder and use one for grinding back to shape and the other for a finer finish. Currently £9 for 2 delivered.

zeppelin builder

Member

- Messages

- 2,133

- Location

- peoples republic of scotland

Green grit (silicon carbide) does the job.

as does any 3m Cubitron

wheel