Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Engineering input please!

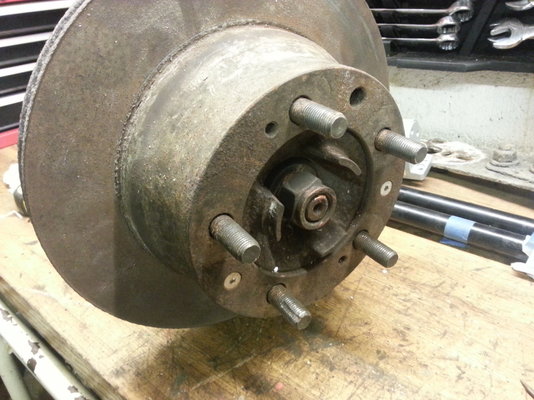

Upgrading the rear suspension of my Sandrail to IRS using the back end off a Porsche 944 S2 Turbo.

This leaves me with a problem in that the Porsche wheel studs are 5 x 130 PCD

and the steel wheels with my big mud tyres on are 4 x 130.

I have looked at lots of options - I don't want to mess with the Porsche studs and disc, converters are non existent and it seems no one is keen on selling just two 15" Porsche wheels from the 1980's.

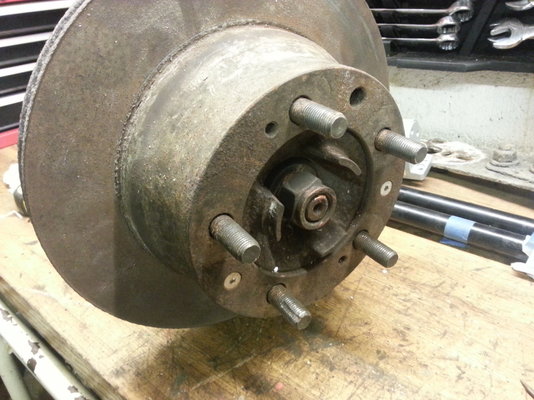

My plan that I would like some input on is to drill and then re-enforce the existing wheels.

First I would have a template made (CNC/waterjet cut) with a combined 4x130 pattern M14 holes (for bolting to the wheel) and 5x 130 pattern with M5 holes for pilot drilling (one would be shared).

Then I was thinking that as the wheel would then have a few extra holes in it and the centre hole is too big for the Porsche centre, I can buy readily available 5mm steel, hub centric spacers to use as backing plates and sandwich the wheel in between.

Any reason this wont work?

Do you think I need the backing plates/spacers?

Better ideas?

Anyone make me a template (for beer tokens of course!)

Upgrading the rear suspension of my Sandrail to IRS using the back end off a Porsche 944 S2 Turbo.

This leaves me with a problem in that the Porsche wheel studs are 5 x 130 PCD

and the steel wheels with my big mud tyres on are 4 x 130.

I have looked at lots of options - I don't want to mess with the Porsche studs and disc, converters are non existent and it seems no one is keen on selling just two 15" Porsche wheels from the 1980's.

My plan that I would like some input on is to drill and then re-enforce the existing wheels.

First I would have a template made (CNC/waterjet cut) with a combined 4x130 pattern M14 holes (for bolting to the wheel) and 5x 130 pattern with M5 holes for pilot drilling (one would be shared).

Then I was thinking that as the wheel would then have a few extra holes in it and the centre hole is too big for the Porsche centre, I can buy readily available 5mm steel, hub centric spacers to use as backing plates and sandwich the wheel in between.

Any reason this wont work?

Do you think I need the backing plates/spacers?

Better ideas?

Anyone make me a template (for beer tokens of course!)