colinh1301

Member

- Messages

- 30

I have a small compact tractor and the gear stick came off in my hand today. Its a simple "L" shap bar which was welded on to a gear linkage. There is no signs of corrosion the weld just came apart. looking at it, it was more like it was soldered than welded - no real penetration. I have a clarke 150A mig welder with normal bog standard wire which I have used succesfully lots of times on steel.. The gas was flwing freely - I think it was the mixed gas but it mig have just been CO2 I cant remember which bottle is fitted. I claned up both bits of metal with the grinder prior to welding. When I tried to weld it just sort of burnt really brightly. Blobs of weld sort of came off and continued to burn really brighlty on the floor ( it reminded me of chemistry at school when you burnt magnesium). The weld just wouldnt take at all.

I dont know if it makes any difference but the wire was right at the end of the drum and ran out.

I'm not sure what the gear linkage is made out of - it looks just like steel to me.

I would relly like to get this sorted tomorrow (day off) so your help would really be appreciated.

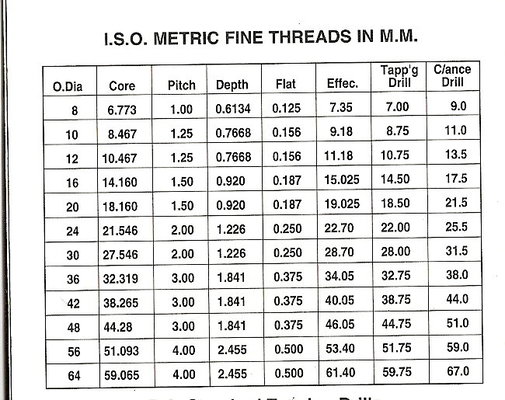

My plan be is to drill and tap it and secure with a bolt. Can someone explain what the relationship is between the required hole size for the various metric threads are.

Cheers

Colin

I dont know if it makes any difference but the wire was right at the end of the drum and ran out.

I'm not sure what the gear linkage is made out of - it looks just like steel to me.

I would relly like to get this sorted tomorrow (day off) so your help would really be appreciated.

My plan be is to drill and tap it and secure with a bolt. Can someone explain what the relationship is between the required hole size for the various metric threads are.

Cheers

Colin