Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

Was sort of forced to have my first go at machining (and welding) aluminum when I overturned my bead roller while tidying up and smashed the flange of the gearbox.

Made a right mess but it could have been worse as the gearbox broke the fall of the inverter. (I Hope)

I have a AC tig and a lathe so maybe all is not lost.

Nothing ventured and all that so stripped it apart and see what to do.

3 of the 4 M6 tapped mounting holes were flubbered and it was cracked around the oil seal.

Cleaned it up a bit with a burr, read @Richard. beginers guide to welding aliminium on here and gave it a go.

I was hampered somewhat as I didn't have any aliminium tig rods but I did have a bit of 0.8 4043 mig wire so wound it together using a drill and had a reasonable approximation with the added benefit that it's easy to feed.

Not pretty and won't pass any weld test (including a visual) but will see how it goes when I try to machine it.

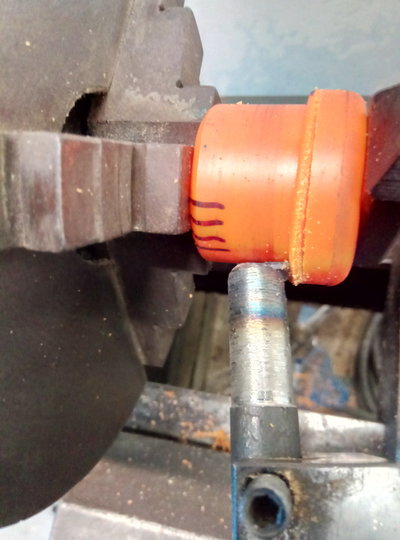

Put it in the 3 jaw on my Boxford and had a go at machining with my Banggood insert tools.

Worked better when I used a bit of release oil for cutting oil and it would actually cut and not just smear the aluminium.

Nearest thing I have to a mill is my drill press so I used a flat faced burr to open out the flats on the through holes.

Again anything but pretty but there was no way I was going to try free hand shaping with a milling cutter in the drill and needs must.

Drilled and tappet the mounting holes and put it back together again and it all fits and even more remarkably it works.

We will see if it lasts, but it's better than throwing it in the bin.

If it comes to it I could machine a new one out of a billet of aluminium but for now I'll call it done.

Made a right mess but it could have been worse as the gearbox broke the fall of the inverter. (I Hope)

I have a AC tig and a lathe so maybe all is not lost.

Nothing ventured and all that so stripped it apart and see what to do.

3 of the 4 M6 tapped mounting holes were flubbered and it was cracked around the oil seal.

Cleaned it up a bit with a burr, read @Richard. beginers guide to welding aliminium on here and gave it a go.

I was hampered somewhat as I didn't have any aliminium tig rods but I did have a bit of 0.8 4043 mig wire so wound it together using a drill and had a reasonable approximation with the added benefit that it's easy to feed.

Not pretty and won't pass any weld test (including a visual) but will see how it goes when I try to machine it.

Put it in the 3 jaw on my Boxford and had a go at machining with my Banggood insert tools.

Worked better when I used a bit of release oil for cutting oil and it would actually cut and not just smear the aluminium.

Nearest thing I have to a mill is my drill press so I used a flat faced burr to open out the flats on the through holes.

Again anything but pretty but there was no way I was going to try free hand shaping with a milling cutter in the drill and needs must.

Drilled and tappet the mounting holes and put it back together again and it all fits and even more remarkably it works.

We will see if it lasts, but it's better than throwing it in the bin.

If it comes to it I could machine a new one out of a billet of aluminium but for now I'll call it done.

Would no other supply do?

Would no other supply do?

I need to make something like that, somewhere I have some A series push rods which I want to use I just need to find them

I need to make something like that, somewhere I have some A series push rods which I want to use I just need to find them