yoshie

Member

- Messages

- 56

- Location

- SW France

Hi all, I have to weld the rear wing on my old Hillman Imp I always have trouble welding large, flat panels without the warping no matter how slowly I do it and giving it lots of times between tacks.

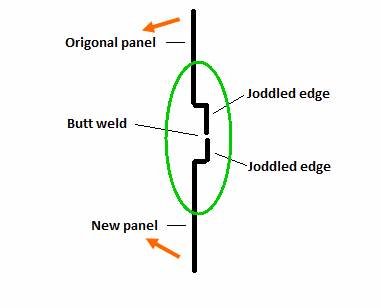

What I'm thinking about trying is joddling about 2mm of the old panel and 2 mm of the replacement panel so the join sits slightly low from the surface of the panel. I've tested on an old bit 1mm steel and joddling an edge certainly makes it a bit more rigid, it would also mean I wouldn't have to grind the weld completely flat and it would just need a skim of filler.

What does the team think..... is it worth while or am I wasting my time or does anyone have any other suggestions.

Thanks in advance

Mike

What I'm thinking about trying is joddling about 2mm of the old panel and 2 mm of the replacement panel so the join sits slightly low from the surface of the panel. I've tested on an old bit 1mm steel and joddling an edge certainly makes it a bit more rigid, it would also mean I wouldn't have to grind the weld completely flat and it would just need a skim of filler.

What does the team think..... is it worth while or am I wasting my time or does anyone have any other suggestions.

Thanks in advance

Mike

, the main problem I have is the panel warping and I was hoping that creating two joddled edges would give some rigidity to the panel but using a butt weld, something like this (hopefully this works) the original and new panel would both have an edge joddled all the way round. The actual width of each joddled part would only be a couple of mm.

, the main problem I have is the panel warping and I was hoping that creating two joddled edges would give some rigidity to the panel but using a butt weld, something like this (hopefully this works) the original and new panel would both have an edge joddled all the way round. The actual width of each joddled part would only be a couple of mm.