You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding 1/4 aluminium advice

- Thread starter yorkie_chris

- Start date

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

@Hood

@bR39Da

Think I'm going to put this on the back burner for the moment lads. Went to R-Tech [once again, very helpful] and priced up the bits I'd need to attempt this. Their email quote, by the time VAT is added and carriage at £17 , comes out at a few pence shy of £70 - this is getting towards the same ballpark as a spool gun like this and would obviate the need to mess with torch liner, feed rollers etc.

, comes out at a few pence shy of £70 - this is getting towards the same ballpark as a spool gun like this and would obviate the need to mess with torch liner, feed rollers etc.

http://www.ebay.co.uk/itm/MIG-TORCH...e=STRK:MEBIDX:IT&_trksid=p2055119.m1438.l2649

Not to say I won't come back to having a go at migging ali but for the moment it's more than I want to pay for an 'experiment'. I really appreciate your advice and offer of help though - another example of how good a place this is.

@bR39Da

Think I'm going to put this on the back burner for the moment lads. Went to R-Tech [once again, very helpful] and priced up the bits I'd need to attempt this. Their email quote, by the time VAT is added and carriage at £17

, comes out at a few pence shy of £70 - this is getting towards the same ballpark as a spool gun like this and would obviate the need to mess with torch liner, feed rollers etc.

, comes out at a few pence shy of £70 - this is getting towards the same ballpark as a spool gun like this and would obviate the need to mess with torch liner, feed rollers etc.http://www.ebay.co.uk/itm/MIG-TORCH...e=STRK:MEBIDX:IT&_trksid=p2055119.m1438.l2649

Not to say I won't come back to having a go at migging ali but for the moment it's more than I want to pay for an 'experiment'. I really appreciate your advice and offer of help though - another example of how good a place this is.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

What bits do you need?

That price was for the teflon liner, U grooved rollers and a pack of 1mm tips + shroud. Factor in that I'd need to switch liners when going back to weld steel etc and it seems less attractive overall.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

You not got Highland Industrial nearby?

For testing out normal rollers would be ok, I welded for years with them, not knowing any better, in fact I even think the TecArc spool gun has serrated rollers, granted it is not pushing the wire far but even still.

For testing out normal rollers would be ok, I welded for years with them, not knowing any better, in fact I even think the TecArc spool gun has serrated rollers, granted it is not pushing the wire far but even still.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

You not got Highland Industrial nearby?

Aye, in Inverness - I'll be there next Thursday for regular hospital clinic appointment.

tom-madbiker

Member

- Messages

- 322

- Location

- Chesham, UK

i welded my sump on my car using a teflon liner in the mig torch and a single roll feed and normal rollers used 5036 1mm wire i think and a 1.2 mm torch tip and pure argon its still going strong 5 years later

tom-madbiker

Member

- Messages

- 322

- Location

- Chesham, UK

i got the teflon liner off ebay i think about a tenner for a 3 meter one

yorkie_chris

Member

- Messages

- 69

Getting close to buying new machine...

Wondering whether the MTS255 is worth the extra over the promig250 for what I want to do.

Any thoughts guys?

Wondering whether the MTS255 is worth the extra over the promig250 for what I want to do.

Any thoughts guys?

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

It has more top end than the other ones you mention which will probably be needed or at least give a comfortable amount capacity spare.

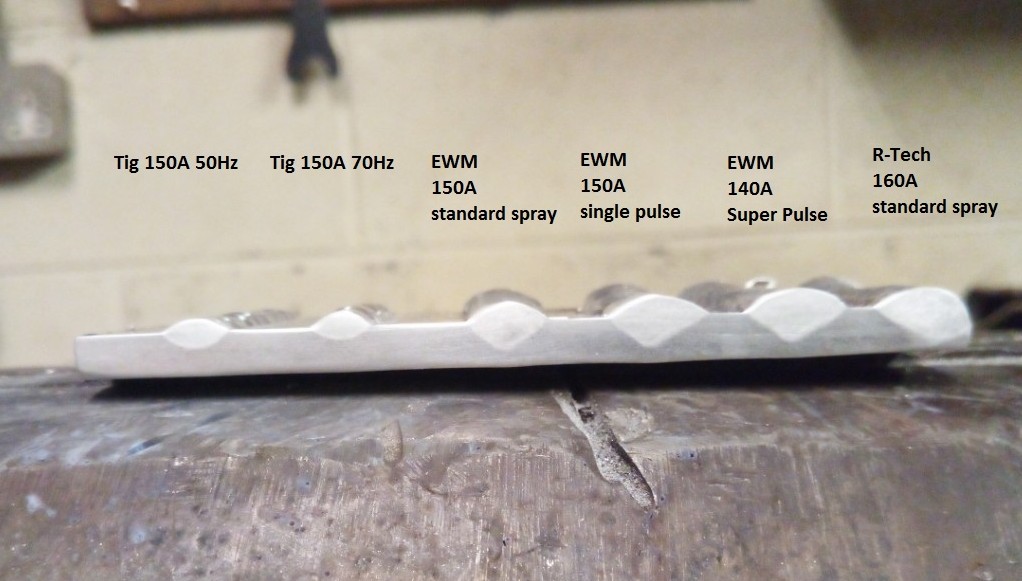

I recently did some tests with Mig and Tig welding Alu as we were having a discussion, the results surprised me a bit regarding the current required with Mig, I always thought it would be more but with the EWM Phoenix Puls it was quite low, with the R-Tech it was higher but still not as high as I had expected. I think it was around about the 160Amps for 5mm but would have to double check. If it was then you would be over 180Amps for 1/4" I would think.

I recently did some tests with Mig and Tig welding Alu as we were having a discussion, the results surprised me a bit regarding the current required with Mig, I always thought it would be more but with the EWM Phoenix Puls it was quite low, with the R-Tech it was higher but still not as high as I had expected. I think it was around about the 160Amps for 5mm but would have to double check. If it was then you would be over 180Amps for 1/4" I would think.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Here it is on 5mm plate I think, the R-Tech one at the righ was on the edge of the plate so really wasn't the best test as it had a kind of an advantage but still.

So basically for a decent weld on 5mm Alu you are looking around about the 160Amp mark with standard spray Mig. The Pulse and super pulse Mig allows lower currents overall but likely peaks as much if not more than the standard spray.

So basically for a decent weld on 5mm Alu you are looking around about the 160Amp mark with standard spray Mig. The Pulse and super pulse Mig allows lower currents overall but likely peaks as much if not more than the standard spray.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Oh sorry, just noticed you were talking the Pro Mig 250 rather than the 180 that doubleboost was using.

So basically the current will be fine so the only difference really will be the Lift Tig functionality and maybe the synergic lines if they work for steel/stainless. They are certainly no use for Alu in my opinion so I just used it in manual.

So basically the current will be fine so the only difference really will be the Lift Tig functionality and maybe the synergic lines if they work for steel/stainless. They are certainly no use for Alu in my opinion so I just used it in manual.

yorkie_chris

Member

- Messages

- 69

Just ordered the 250

yorkie_chris

Member

- Messages

- 69

So with the promig 250, a teflon liner from weldac in halifax, pure argon, 5356 1.2mm wire, U rollers from Rtech... we have some bits stuck together

If I had a quid for every time some of the local experts had told me it was impossible... lol...

I seem to be getting quite a lot of fine white dust on everything, but no spatter. Is this normal?

It's quite fussy for you getting all the crap off especially when welding back into your tacks. Need some different brushes for the drill to get awkward corners cleared out as it seems really easy to just end up bogging chewing gum everywhere and not getting a decent penetration if it's no clean.

Had to bump the plate thickness up to 8mm as well, but it seems to be hacking it ok. Got the voltage up at about 90% of max and wire speed probably about 70%

If I had a quid for every time some of the local experts had told me it was impossible... lol...

I seem to be getting quite a lot of fine white dust on everything, but no spatter. Is this normal?

It's quite fussy for you getting all the crap off especially when welding back into your tacks. Need some different brushes for the drill to get awkward corners cleared out as it seems really easy to just end up bogging chewing gum everywhere and not getting a decent penetration if it's no clean.

Had to bump the plate thickness up to 8mm as well, but it seems to be hacking it ok. Got the voltage up at about 90% of max and wire speed probably about 70%

yorkie_chris

Member

- Messages

- 69

Not sure on gas flow, will have a look next time I'm up there. Was getting loads of black soot before I upped the gas once. I need to put a proper flow meter on it as it just has a single stage reg on that came with the welder.

Regarding the stick out, what is the symptom of that? The white dust or can you see something else on the pic? I am having a few problems with it burning back and sticking to the tip when stopping the weld as it is. Is it normal to make the stickout longer when filling the crater at the end to avoid this?

Regarding the stick out, what is the symptom of that? The white dust or can you see something else on the pic? I am having a few problems with it burning back and sticking to the tip when stopping the weld as it is. Is it normal to make the stickout longer when filling the crater at the end to avoid this?