Bryan Williams

Member

- Messages

- 1,232

- Location

- Manchester England

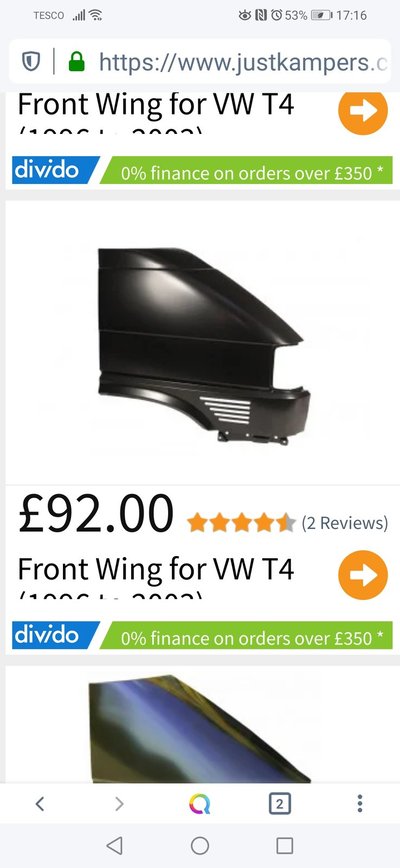

My van needs 2 front wings.

My van needs 2 front wings.These are weld on.

A year later they switched to bolt on.

Been on a few forums, some lads have bought the bolt on later wings and drilled /fettled these to fit.

The bolt on are twice the price though.

Other lads have drilled the weld on wings and bolted them on.. This appeals to me more.

They aren't massive wings the spotwelds are accessible,apart from the vertical door area, the doors may need to come off, I can't see if it is bonded, welded or just floating in the door jamb area.

My plan would be to drill the spots out with a spotweld bit carry the holes through, bolt or rivnut the new ones on, they are bonded around the wheel arch, this is none existant due to rust.

I also have to weld on the lip of the bottom of the inner wings that have rotted away.

My welding skills are basic, I have welded 2mm with arc.

I have a couple of buzz boxes which would blow through this stuff, but I do have a little inverter that the amps get low enough for me to lay small beads.

Just basically asking is bolting weld on wings viable, or should I attempt to spot weld or get someone to mig it.. do rivnuts work?

I think welding a strip of steel along the arch of the inner wing is doable, these vans are a bit sturdier than modern stuff, so I should be able to tack a piece with the inverter.. any thoughts or tips would be appreciated.

One other thing, I read in one forum post that it was the posters opinion if it was originally welded then it's structural so part of the chassis so should always be welded when replacing.

Can't see this but curious as to what people think.

Cheers.