Another Christmas hols project . Bought a Dixon type QCTP off @HughF beginning of the year which was in great nick with lots of toolholders but never got round to fitting it....until last weekend

. Bought a Dixon type QCTP off @HughF beginning of the year which was in great nick with lots of toolholders but never got round to fitting it....until last weekend

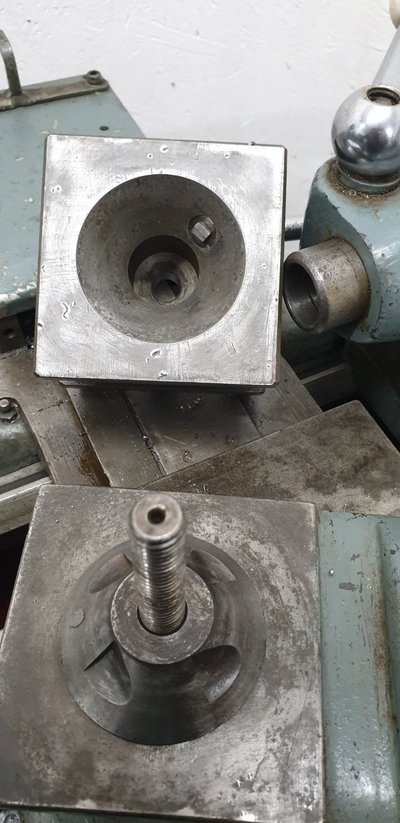

This is the original toolpost.

Mounts on a rotating cuff that is pegged into the retaining post/bolt

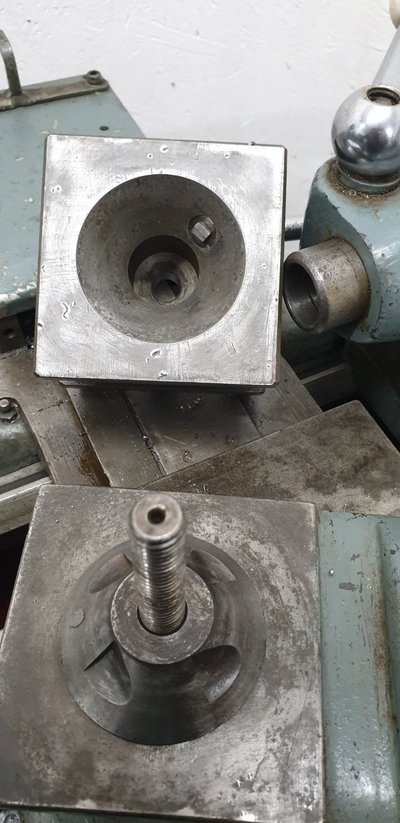

Thats great apart from the Dixon type has a larger retaining bolt which has a square dovetail/slide fitting into the compound rather than the original round/pressed fitting

Machining the underside of the compound to take the new post seemed like overkill so seemed like the pragmatic approach was to sleeve the new mount to snug up onto the original post.

As it happened I had sorted out my steel stock about 4 weeks ago, dragged it out of storage (on the floor ) and cut it down so it would fit into a corner of the machine shop I could actually get too.

) and cut it down so it would fit into a corner of the machine shop I could actually get too.

And that meant I could actually find some bright steel rod which was a pretty much perfect diameter for the inside of the new toolpost holder

So drilled and reamed out the internal bore so it was a nice snug fit over the retaining bolt

and then an easy press fit into the toolpost itself.

Then could re-assemble using the clamping washer from the new toolpost which is bevelled to centre the toolpost on the bolt and the original tool post handle.

Now I just need to find enough uses for all the holders

Seems to clamp down and hold really nicely and now means I can set the centre height accurately for each tool/holder and swap around quickly.

This was my own theory on how to solve the problem, so just checking with you experienced machinists - any issues with taking this approach to fitting the new QCTP?

Cheers,

Paul.

. Bought a Dixon type QCTP off @HughF beginning of the year which was in great nick with lots of toolholders but never got round to fitting it....until last weekend

. Bought a Dixon type QCTP off @HughF beginning of the year which was in great nick with lots of toolholders but never got round to fitting it....until last weekend

This is the original toolpost.

Mounts on a rotating cuff that is pegged into the retaining post/bolt

Thats great apart from the Dixon type has a larger retaining bolt which has a square dovetail/slide fitting into the compound rather than the original round/pressed fitting

Machining the underside of the compound to take the new post seemed like overkill so seemed like the pragmatic approach was to sleeve the new mount to snug up onto the original post.

As it happened I had sorted out my steel stock about 4 weeks ago, dragged it out of storage (on the floor

) and cut it down so it would fit into a corner of the machine shop I could actually get too.

) and cut it down so it would fit into a corner of the machine shop I could actually get too.

And that meant I could actually find some bright steel rod which was a pretty much perfect diameter for the inside of the new toolpost holder

So drilled and reamed out the internal bore so it was a nice snug fit over the retaining bolt

and then an easy press fit into the toolpost itself.

Then could re-assemble using the clamping washer from the new toolpost which is bevelled to centre the toolpost on the bolt and the original tool post handle.

Now I just need to find enough uses for all the holders

Seems to clamp down and hold really nicely and now means I can set the centre height accurately for each tool/holder and swap around quickly.

This was my own theory on how to solve the problem, so just checking with you experienced machinists - any issues with taking this approach to fitting the new QCTP?

Cheers,

Paul.