northwest

Searching for the Holy Grail.........

- Messages

- 5,398

- Location

- Manchester UK

So, I am trying to install a turning target system for the gun club.

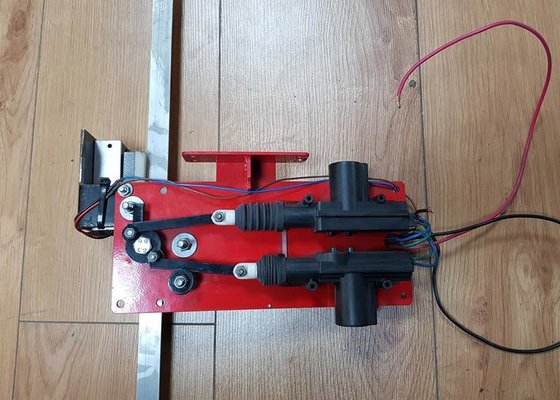

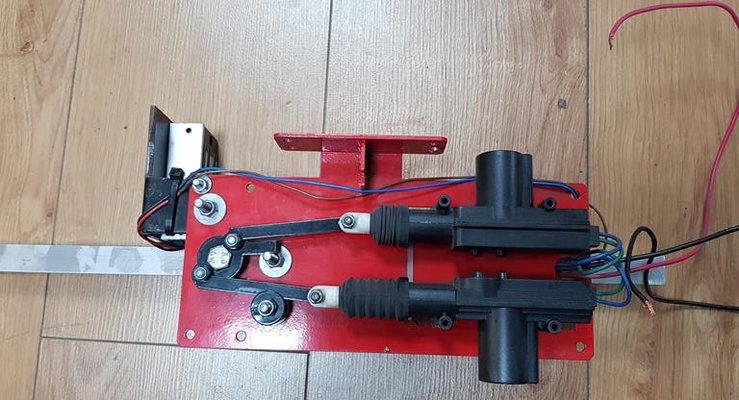

About four months ago we bought this prototype system from someone to get us a turning target system going. I installed it and made the hanging target holding frames for it. It did not perform to expectations and since it is "electronic" I gave it to someone familiar with these Dark Arts to sort out.

As is almost always the case with these things, it has ended up back in my lap.

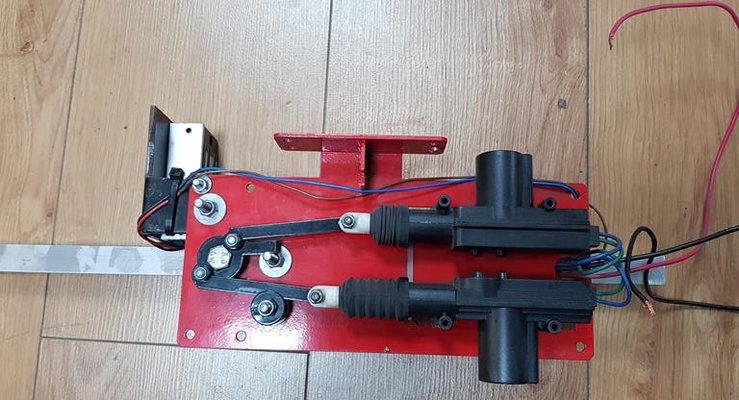

It does everything we want it to, in theory. As you can see from the controller it has turn, delay, timing, frequency and so on. In practice however it just will not work. The unit itself does everything as advertised.

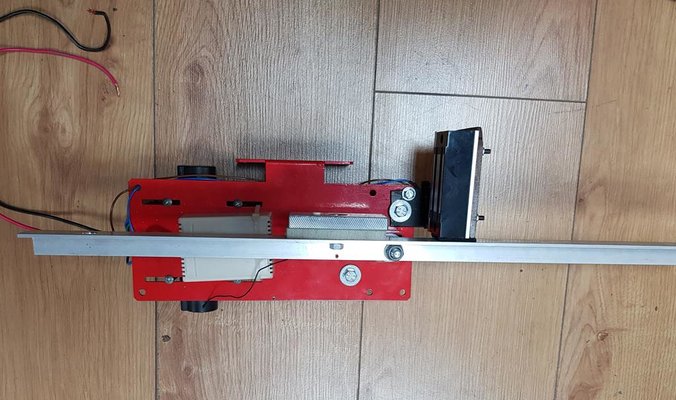

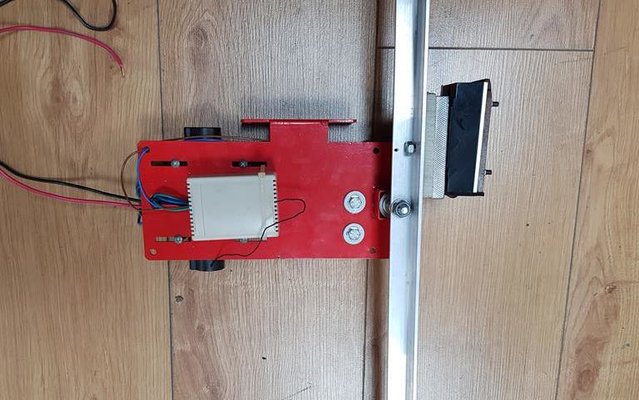

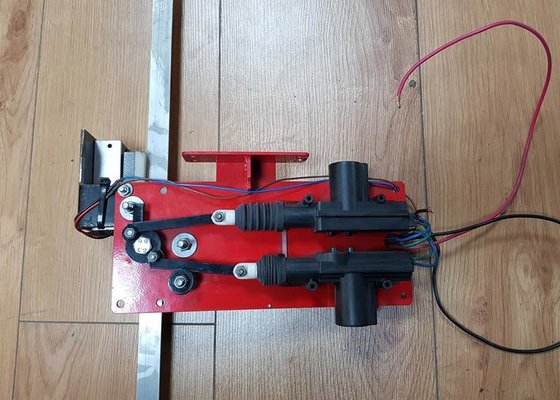

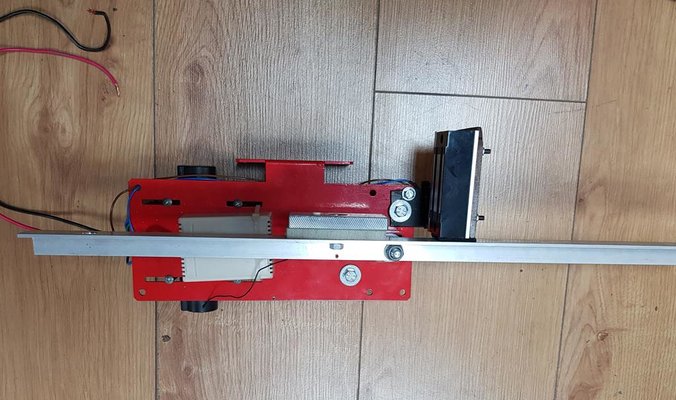

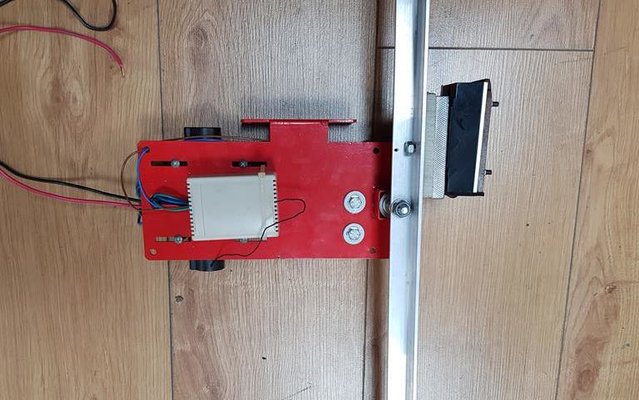

The shortcomings are these: It turns just fine, reaches the end of travel and immediately bounces half way back. I think this is because these are motors and not solenoids on a rack and pinion arrangement. One of the guys that looked at it has fitted an electro magnet to try to hold it in place when it turns, this doesn't work either. I think the answer here are solenoids that hold in place.

The other problem which is mechanical is that the nut holding the aluminium bar in place comes undone really quickly so that is something I can easily fix.

The frame will be held vertically under a bit of tension using a bungee rope from the middle of the frame to a weight on the floor, I have used this in the past and it is a simple solution allowing the target to turn and keep the frame in place.

What I am asking for here are some suggestions as to how to mechanically move the target frame, the electronics work just fine, it is the implementation that doesn't work. I have a suspicion that I will be totally redesigning the linkage and pivot but I have no recent experience of the type of actuators that are available now. I could do it with pneumatics , but that is just totally impractical so I would welcome all and any suggestion as to how to accomplish this.

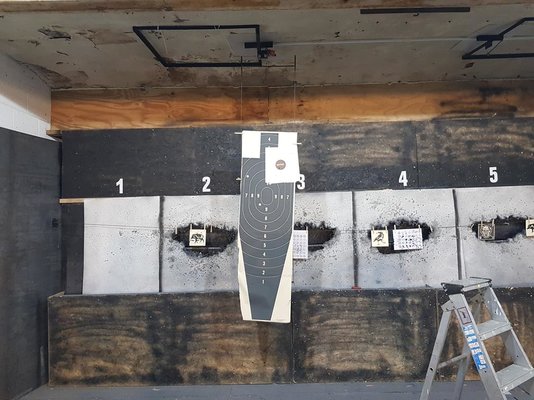

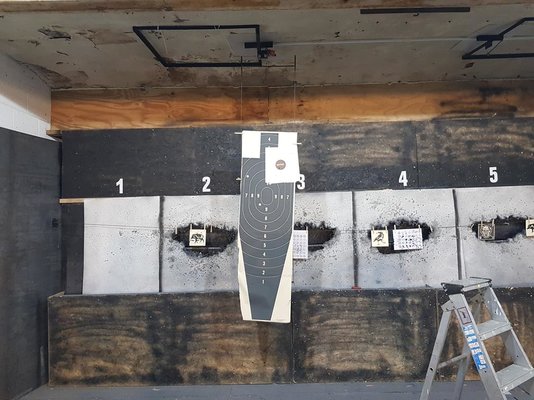

The large black frames attached to the ceiling are because the ceiling is very soft in places and I needed to anchor the system firmly, this has worked well by giving a large area to choose from. The wires are all 12 volt and cannot be seen and are protected from the firing points.

About four months ago we bought this prototype system from someone to get us a turning target system going. I installed it and made the hanging target holding frames for it. It did not perform to expectations and since it is "electronic" I gave it to someone familiar with these Dark Arts to sort out.

As is almost always the case with these things, it has ended up back in my lap.

It does everything we want it to, in theory. As you can see from the controller it has turn, delay, timing, frequency and so on. In practice however it just will not work. The unit itself does everything as advertised.

The shortcomings are these: It turns just fine, reaches the end of travel and immediately bounces half way back. I think this is because these are motors and not solenoids on a rack and pinion arrangement. One of the guys that looked at it has fitted an electro magnet to try to hold it in place when it turns, this doesn't work either. I think the answer here are solenoids that hold in place.

The other problem which is mechanical is that the nut holding the aluminium bar in place comes undone really quickly so that is something I can easily fix.

The frame will be held vertically under a bit of tension using a bungee rope from the middle of the frame to a weight on the floor, I have used this in the past and it is a simple solution allowing the target to turn and keep the frame in place.

What I am asking for here are some suggestions as to how to mechanically move the target frame, the electronics work just fine, it is the implementation that doesn't work. I have a suspicion that I will be totally redesigning the linkage and pivot but I have no recent experience of the type of actuators that are available now. I could do it with pneumatics , but that is just totally impractical so I would welcome all and any suggestion as to how to accomplish this.

The large black frames attached to the ceiling are because the ceiling is very soft in places and I needed to anchor the system firmly, this has worked well by giving a large area to choose from. The wires are all 12 volt and cannot be seen and are protected from the firing points.