Submariner1

Member

- Messages

- 194

- Location

- Berkshire

New compressor manual says you must check torque setting on Head bolts before first use (note The small print warns omission to do this will void warranty!).

1. The manual omits to say check when cold ... a usual convention. I assume this is also applicable for compressor pumps?

2. The manual covers 5 compressors ... my pet hate. So it shows a table for 5 cylinder head bolt sizes.

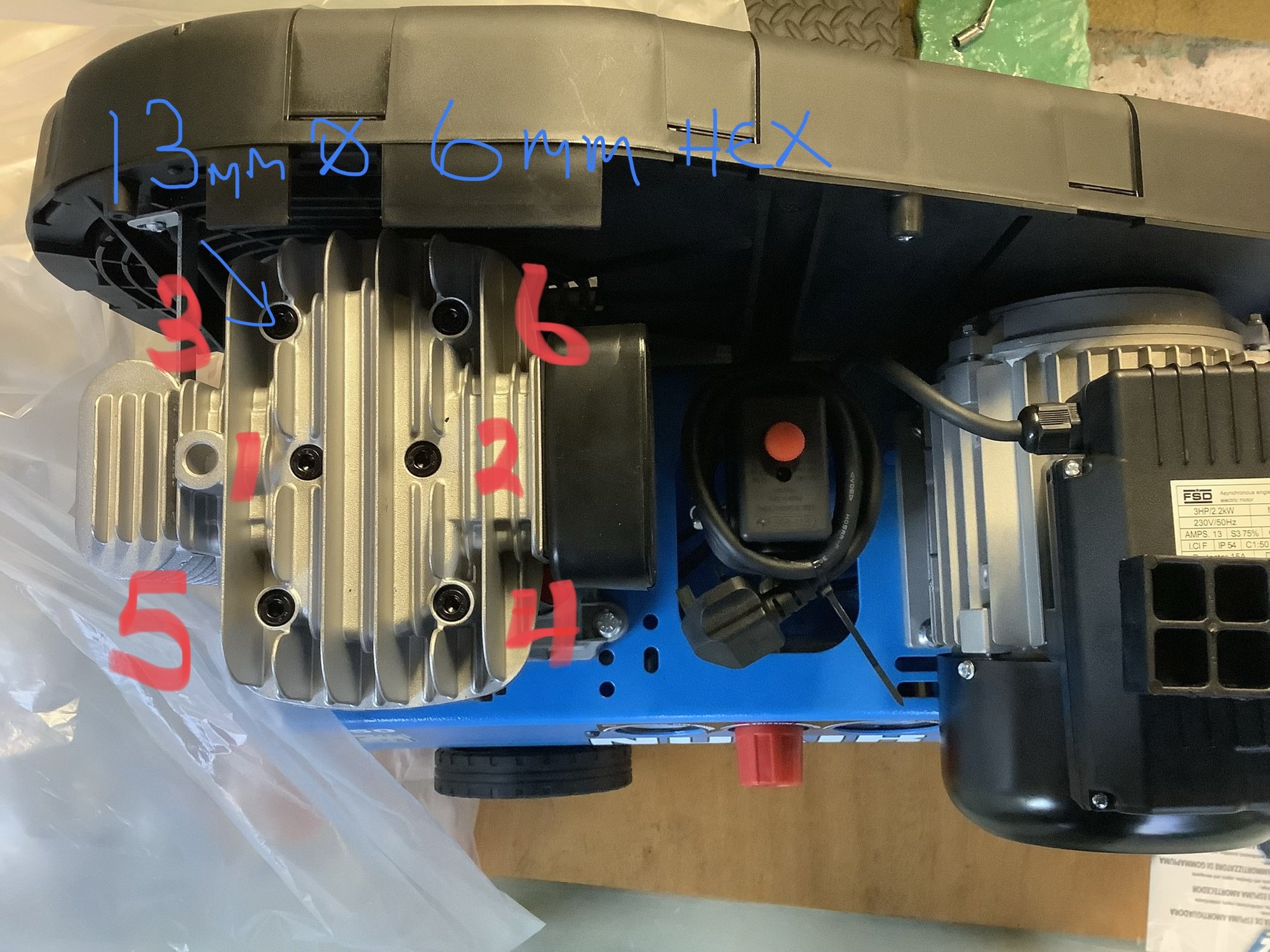

The cap screws on my pump are just under 13mm head diameter and take a 6mm Hex key. I assume they are therefore 8mm cap screws?

These require 22 to 27 Nm torque.

The next size down is an M6 bolt requiring 9 To 11 Nm Torque.

It would be reassuring to know if anyone has one of these B2800B 12 CFM 3HP pumps (used in Nuair, ABAC Fini etc.) and knows for sure, that its definitely an M8 bolt (I don't want to undo one, to definitely verify it’s an M8 bolt diam.

I only ask as mfg’s sometimes have access to odd head sizes, and Numatic do use a 15mm hex head socket on their 12mm diam wheel shaft. (M12 are normally 19mm spanners)

3. They do not specify the Head Bolt torque order of tightening in the manual

In the pic below is the Order / Sequence I would do it in ... but is this correct?

pump looks like this

Any advice appreciated

1. The manual omits to say check when cold ... a usual convention. I assume this is also applicable for compressor pumps?

2. The manual covers 5 compressors ... my pet hate. So it shows a table for 5 cylinder head bolt sizes.

The cap screws on my pump are just under 13mm head diameter and take a 6mm Hex key. I assume they are therefore 8mm cap screws?

These require 22 to 27 Nm torque.

The next size down is an M6 bolt requiring 9 To 11 Nm Torque.

It would be reassuring to know if anyone has one of these B2800B 12 CFM 3HP pumps (used in Nuair, ABAC Fini etc.) and knows for sure, that its definitely an M8 bolt (I don't want to undo one, to definitely verify it’s an M8 bolt diam.

I only ask as mfg’s sometimes have access to odd head sizes, and Numatic do use a 15mm hex head socket on their 12mm diam wheel shaft. (M12 are normally 19mm spanners)

3. They do not specify the Head Bolt torque order of tightening in the manual

In the pic below is the Order / Sequence I would do it in ... but is this correct?

pump looks like this

Any advice appreciated