You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torch type

- Thread starter Daz1968

- Start date

gordon stephenson

Member

- Messages

- 7,430

- Location

- Skelton in Cleveland U.K.

For your requirements I would be using aN MB 15 torch with 3 mtr length, you might get away with a 4 mtr if you need the extra length,

I am pretty sure it is in the liner or torch as it will fold between roller and tube at back of the euro connector if I increase tension, so it's past the roller where the problem is, for the cost of a liner I may as well try a blue one designed for this size wire as if I hold torch straight it feeds better. It's just frustrating when trying to make a decent weld, the torch itself is not very old so a liner is cheapest option to try first,

Thanks for advice

Thanks for advice

Kent

Member

- Messages

- 9,914

- Location

- Bowland, Lanacshire,UK

you know that solid tube to which you refer, just run through it with a small drill bit turning it by hand only, thing is they often get full of crud and the hole narrows. Straightening the torch will always get a smoother feed, if you have an issue at the rollers (have you checked your on the right groove) or the tube to which I refer or the liner is a bit shot straightening just gives it a bit back

wyn

Member

- Messages

- 3,766

- Location

- Cardiff

I am pretty sure it is in the liner or torch as it will fold between roller and tube at back of the euro connector if I increase tension, so it's past the roller where the problem is

The liner or tube needs to reach right up to the roller...you shouldn't have much of a gap to allow the wire to birds nest.

Kent

Member

- Messages

- 9,914

- Location

- Bowland, Lanacshire,UK

Not all plants set up this way. Many use a rigid tube inbetween the liner and the rollersThe liner or tube needs to reach right up to the roller...you shouldn't have much of a gap to allow the wire to birds nest.

Woody.v8

Blue gluer

- Messages

- 4,218

- Location

- staffs

Exactly, with a euro torch the liner starts in the plug not the feeder.Not all plants set up this way. Many use a rigid tube inbetween the liner and the rollers

NickyEng

Brown belt in Origami

- Messages

- 826

- Location

- Argyll Scotland

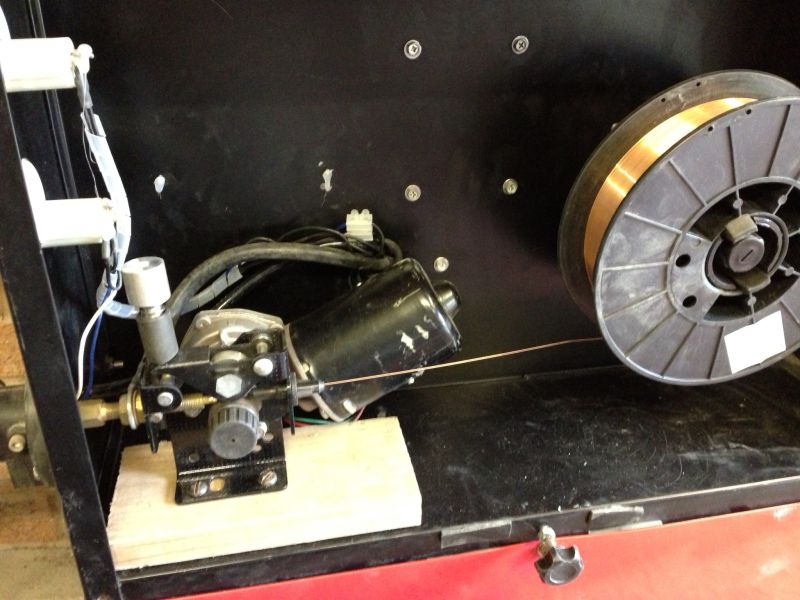

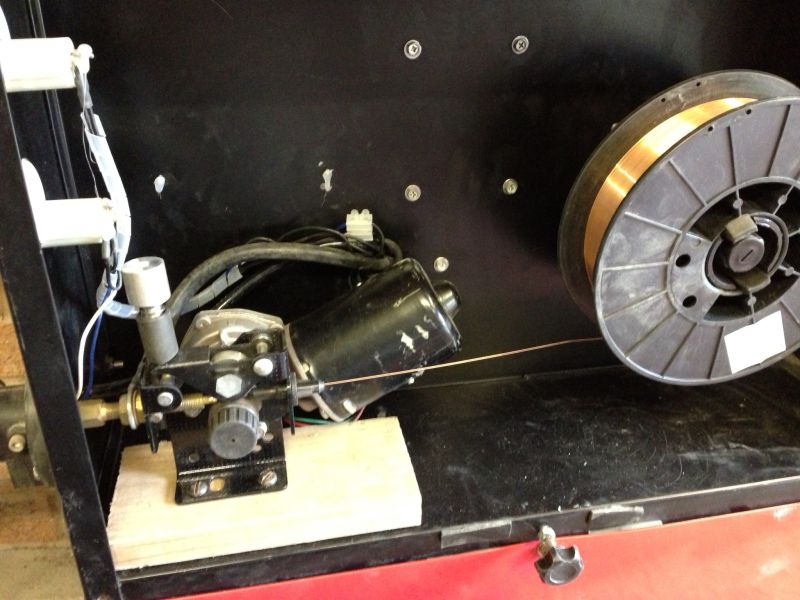

Yes all my mig welders have a brass rigid tube from the rollers to the euro torch connectionNot all plants set up this way. Many use a rigid tube inbetween the liner and the rollers

This is only picture I have of my wire feed, I know the motor is running fine, and when it does feed the weld quality is perfect for my needs. It's just sometimes it jams, if I adjust rollers correct it just slips which is what I would expect. It's only when I put too much pressure on I have problems at this end. Don't think I can get the tube any closer to wheel. Hopefully correct sized liner and new tips will solve it. The motor is an upgrade I fitted and is probably overkill for my needs but is working fine.