JOEPRO

Member

- Messages

- 5,203

- Location

- UK

Its pretty amazing isn't it. The shot blasting process. You can take old gnarly looking rusted parts and blast off decades of grot revealing a shiny part below.

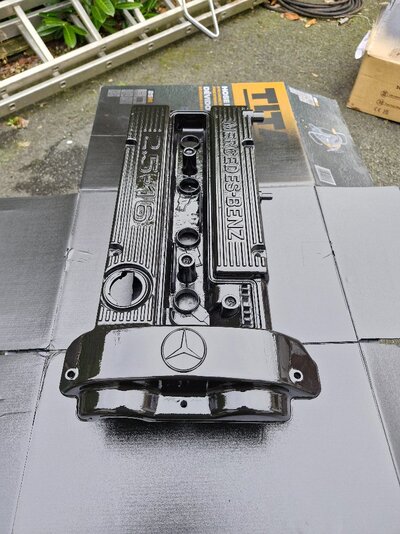

Just finished with this old magnesium valve cover. It had many layers of paint and a super tough original coating of paint.

I started shot blasting it with recycled glass bead and it was taking way too long to break through the old paint. So I lashed it in paint stripper, covered it with a bin liner so the stripper wouldn't dry off and left it all day. The remaining old paint was loosened

I then used my Lavor hot diesel washer and a 15 degree nozzle and blasted off as much paint as I could. Then about 1 hour covered it all well in my shot blast cabinet

Some imperfections are showing so tomorrow I will use a small qty of body filler to fill those and spray it with several coats of gloss black high temp caliper paint.

Just finished with this old magnesium valve cover. It had many layers of paint and a super tough original coating of paint.

I started shot blasting it with recycled glass bead and it was taking way too long to break through the old paint. So I lashed it in paint stripper, covered it with a bin liner so the stripper wouldn't dry off and left it all day. The remaining old paint was loosened

I then used my Lavor hot diesel washer and a 15 degree nozzle and blasted off as much paint as I could. Then about 1 hour covered it all well in my shot blast cabinet

Some imperfections are showing so tomorrow I will use a small qty of body filler to fill those and spray it with several coats of gloss black high temp caliper paint.