lchris21

Member

- Messages

- 2,014

- Location

- South Wales

Morning all,

Got a small project on the horizon which includes replacing the filler neck on a steel motorcycle petrol tank. I've done a few repairs over the years, mods etc and have noticed some production tanks have the filler neck, or fuel pump flanges etc brazed in?

The Tig weld repairs I've carried out just with some patches to old tanks, the odd bung, pipe etc has not really distorted to badly.

This job will involve the complete removal and replacement of the filler neck, that's going to stare you in the chops! so I'm concerned the stresses induced during the forming of the tank will decide to make their great escape during the welding process. With a wonky cap as a result.

Will using some flavour of silicon bronze filler reduce the heat and fingers crossed the potential distortion?

I've used the tig, cool, tig, cool technique on small flatter sections some other jobs in the past, which had limited or random success in reducing distortion?

Cheers

Got a small project on the horizon which includes replacing the filler neck on a steel motorcycle petrol tank. I've done a few repairs over the years, mods etc and have noticed some production tanks have the filler neck, or fuel pump flanges etc brazed in?

The Tig weld repairs I've carried out just with some patches to old tanks, the odd bung, pipe etc has not really distorted to badly.

This job will involve the complete removal and replacement of the filler neck, that's going to stare you in the chops! so I'm concerned the stresses induced during the forming of the tank will decide to make their great escape during the welding process. With a wonky cap as a result.

Will using some flavour of silicon bronze filler reduce the heat and fingers crossed the potential distortion?

I've used the tig, cool, tig, cool technique on small flatter sections some other jobs in the past, which had limited or random success in reducing distortion?

Cheers

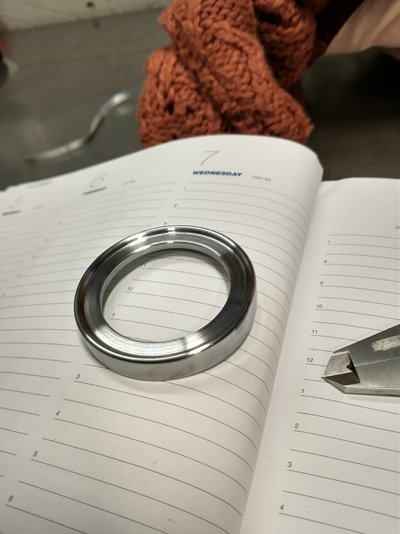

.....not too bad in the end, lots of air cooling and good fit up, small 10mm sections in opposite quadrants....very little distortion. Bit on one side where it keyholed on a thin stretched part of the tank. My painter has had much much worse off me

.....not too bad in the end, lots of air cooling and good fit up, small 10mm sections in opposite quadrants....very little distortion. Bit on one side where it keyholed on a thin stretched part of the tank. My painter has had much much worse off me