- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Think I might have purchased an Atlas Lathe!!!

- Thread starter Exuptoy

- Start date

God mode restorations

Member

- Messages

- 8,150

- Location

- uk colchester

Got ya... didn't realise.But it must be meant to have a 2 stage pulley @spencer 427 as the head pulley has the second ring.

Kram

Member

- Messages

- 8,365

- Location

- Sussex

Let me know if you need help with the pulley, I have made a few recently  One thing stands out is the small pulley has a tiny OD for an A section belt, if the drawing is correct? This may give problems unless the opposing pulley is quite large or far away - even so you'd want an XPA style belt. The minimum recommended in a couple of belt manufactures design guide is ~63mm pitch and yours looks like 38mm pitch?

One thing stands out is the small pulley has a tiny OD for an A section belt, if the drawing is correct? This may give problems unless the opposing pulley is quite large or far away - even so you'd want an XPA style belt. The minimum recommended in a couple of belt manufactures design guide is ~63mm pitch and yours looks like 38mm pitch?

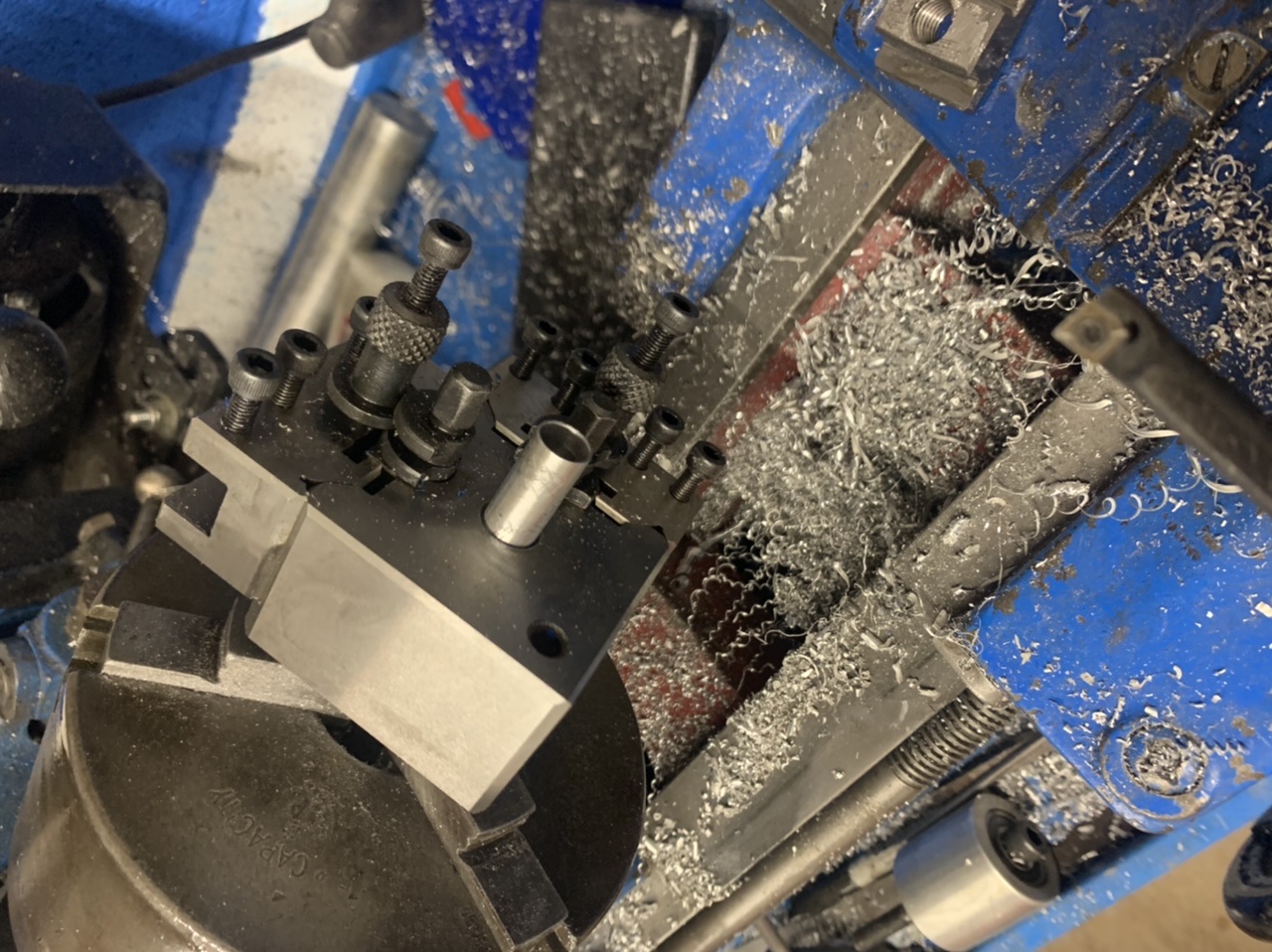

I've found much easier to make the pulleys in two pieces, shrink fit the larger one, that way you have plenty of clearance to use an VCGT1604 tool, which is almost the correct angle for this.

One thing stands out is the small pulley has a tiny OD for an A section belt, if the drawing is correct? This may give problems unless the opposing pulley is quite large or far away - even so you'd want an XPA style belt. The minimum recommended in a couple of belt manufactures design guide is ~63mm pitch and yours looks like 38mm pitch?

One thing stands out is the small pulley has a tiny OD for an A section belt, if the drawing is correct? This may give problems unless the opposing pulley is quite large or far away - even so you'd want an XPA style belt. The minimum recommended in a couple of belt manufactures design guide is ~63mm pitch and yours looks like 38mm pitch?I've found much easier to make the pulleys in two pieces, shrink fit the larger one, that way you have plenty of clearance to use an VCGT1604 tool, which is almost the correct angle for this.

Exuptoy

Member

- Messages

- 3,135

- Location

- Maesteg, South Wales

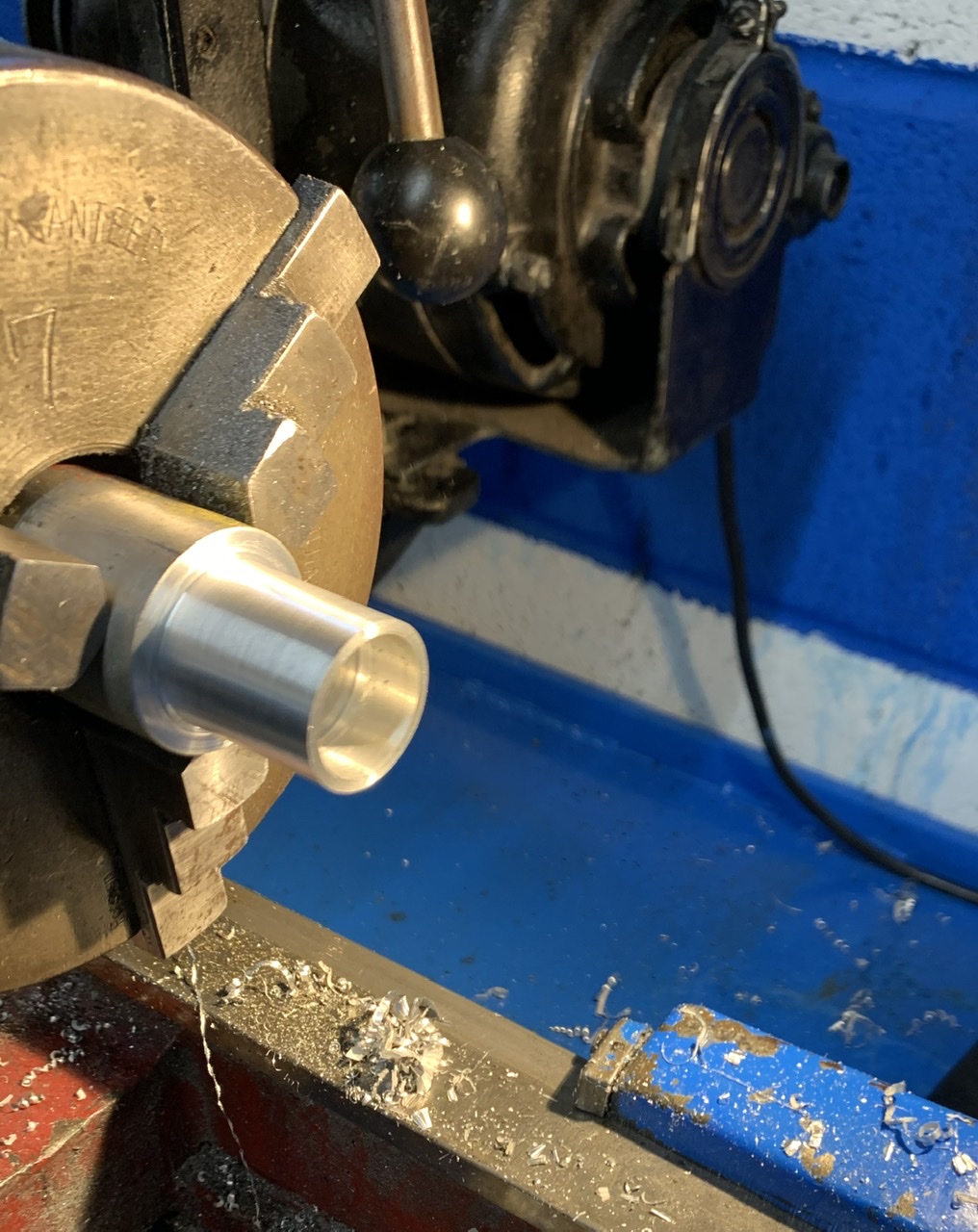

Got given a 1/2 inch Sandvik tipped internal boring tool today by one of the fitters in work. What a difference to the finish straight from the tool with no messing around with files or sandpaper! Also managed it with the auto feed on!

Also managed it with the auto feed on!

Also managed it with the auto feed on!

Also managed it with the auto feed on!

Gritineye

Member

- Messages

- 2,098

You probably know this already, but that way wiper with the hole in it, they should have a bit of L shaped rubber with felt behind them.

Worth having a look very so often, clean and oil them, put them back making sure the rubber and felts are in contact with the ways.

An good squirt with oil can in the 4 holes every day soaks the L shaped felt which should get under the carriage and down the back of the ways and lube the rear gibs, and underside of the ways, which are hard to get at otherwise.

Worth having a look very so often, clean and oil them, put them back making sure the rubber and felts are in contact with the ways.

An good squirt with oil can in the 4 holes every day soaks the L shaped felt which should get under the carriage and down the back of the ways and lube the rear gibs, and underside of the ways, which are hard to get at otherwise.

Exuptoy

Member

- Messages

- 3,135

- Location

- Maesteg, South Wales

What grade of oil we speaking about? @Gritineye

Exuptoy

Member

- Messages

- 3,135

- Location

- Maesteg, South Wales

This lathe is getting lots of work and is a pleasure to use. It’s not as agricultural as I initially thought, you just have to allow for its size when cutting etc.

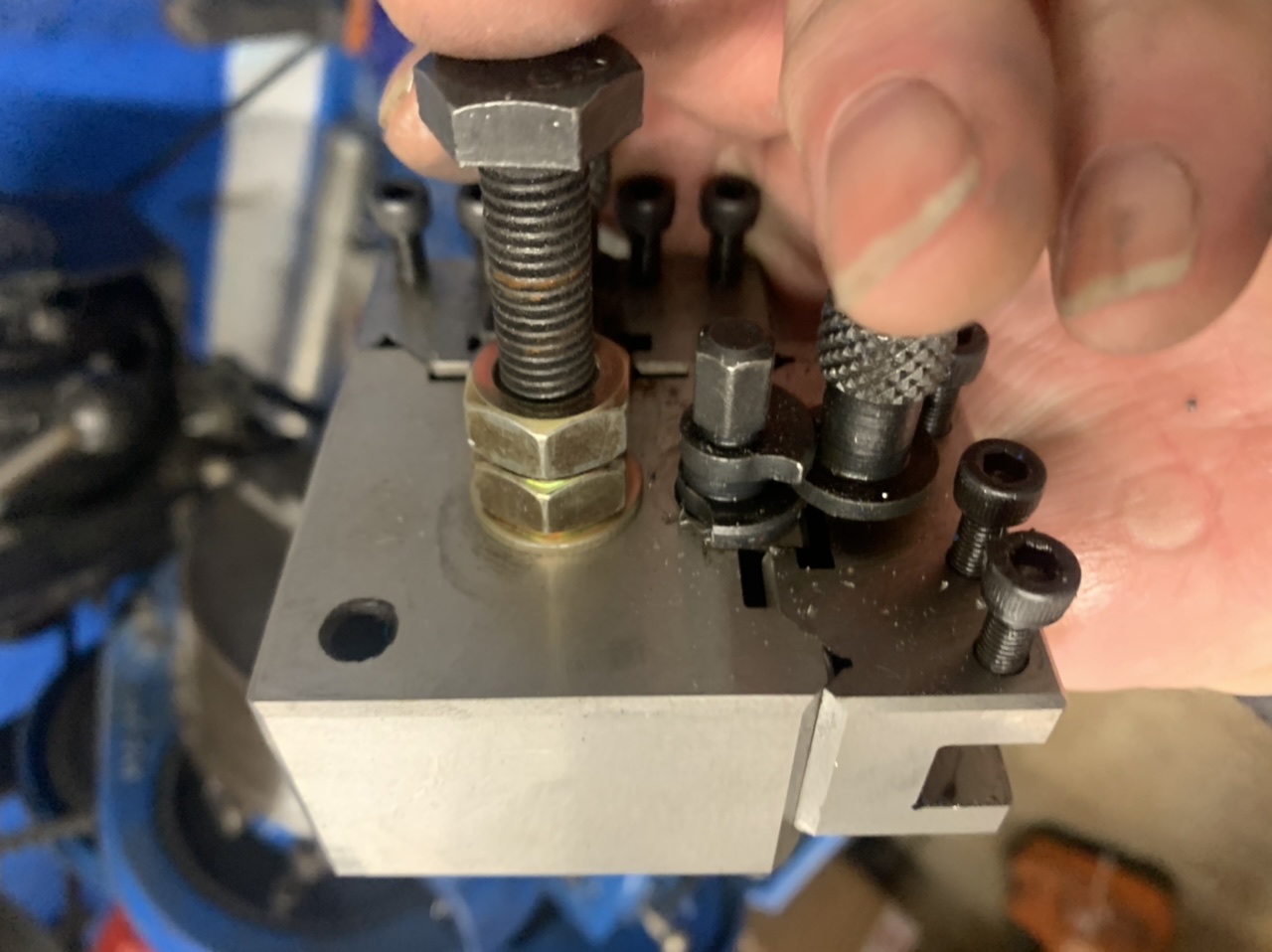

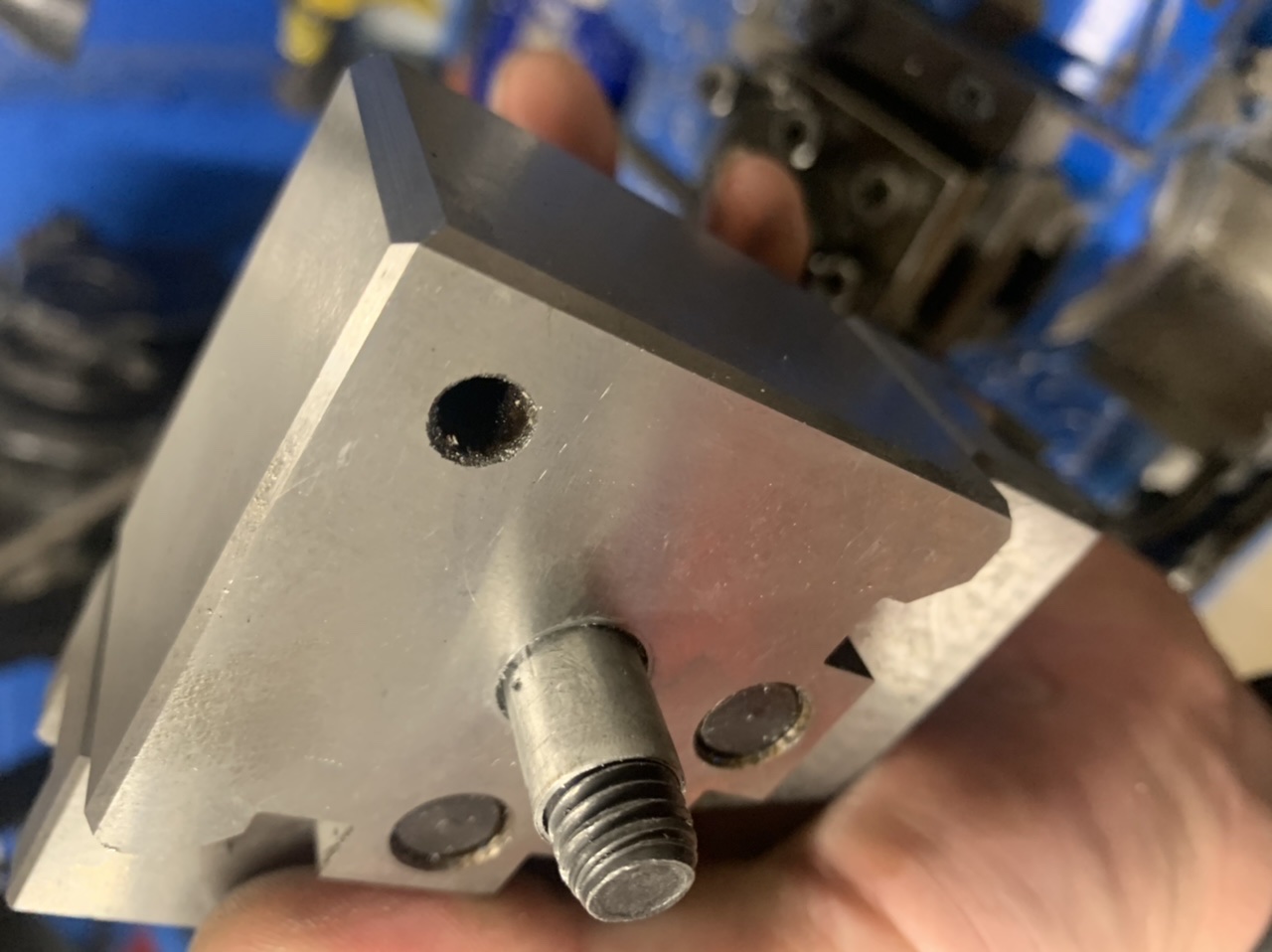

I have purchased a T37 qctp which is actually too small (T51 May be better) but it’s ok. I didn’t have and 7/16 stud here so went with 10mm for now which meant a smaller T-slot nut and a sleeve on the tool post. I’ll do a steel one maybe or just order 7/16 stud and make a new T-Slot nut. Mine is 1/2 inch.

oh yeah, I forgot, the T-slot nut was made by welding 2 pieces of 5mm steel together and using the milling slide to cut the welds back.

I have purchased a T37 qctp which is actually too small (T51 May be better) but it’s ok. I didn’t have and 7/16 stud here so went with 10mm for now which meant a smaller T-slot nut and a sleeve on the tool post. I’ll do a steel one maybe or just order 7/16 stud and make a new T-Slot nut. Mine is 1/2 inch.

oh yeah, I forgot, the T-slot nut was made by welding 2 pieces of 5mm steel together and using the milling slide to cut the welds back.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,558

- Location

- France, Brittany.

Glad to see your enjoying your lathe.

I'm missing mine badly in this lockdown...

And my welders...

Back to plasterboarding.. Ughh.

I'm missing mine badly in this lockdown...

And my welders...

Back to plasterboarding.. Ughh.

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,540

- Location

- The Shed of Danger, surrey, England

I'd make that tee nut longer if I were you. It's a bit short and would be more likely to rip the tee slot out if you get a dig-in.

Mine I made is full width too, and pretty snug in the slot - after milling it I blued it and scraped to fit the slot perfectly so the load was evenly spread.

Dave H. (the other one)

Exuptoy

Member

- Messages

- 3,135

- Location

- Maesteg, South Wales

I'd make that tee nut longer if I were you. It's a bit short and would be more likely to rip the tee slot out if you get a dig-in.

I just copied the size of my existing one. It was 1” square. You are correct though, there is movement there side to side. Once Ive mounted the QCTP I’ll make another.