Paulbarrett

Member

- Messages

- 1,141

- Location

- Northampton

It’s still available@Paulbarrett had one for sale from Welder Paul's workshop. Not sure if it's gone now.

It’s still available@Paulbarrett had one for sale from Welder Paul's workshop. Not sure if it's gone now.

I'm enjoying this thread on a number of levels. Keep up the hard work.Thanks for the moral support everyone. As I said a little earlier this is a retrospective so the damage is already done so to speak!

I do feel very bad for making the little m type (it’s actually a lovely machine) do that but needs musted I’m afraid…

What makes it worse is have both! I haven’t had time to get my Cardiff lathe off the ground which even in its shagged out state would have probably enjoyed munching it’s way through that bit of steel!

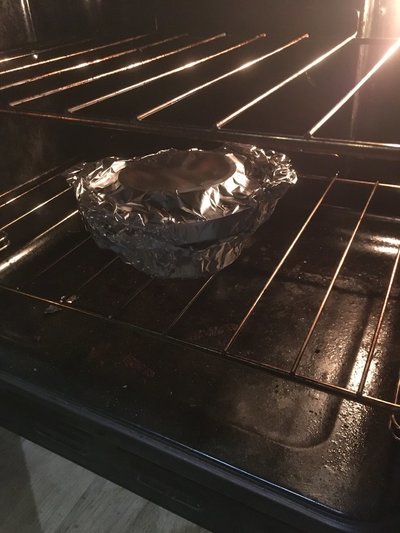

And the picture below explains exactly why I can’t use my bandsaw. Let’s just say the mill isn’t the only thing that’s a shambles…View attachment 421083

My garage is worse, I’m to ashamed to post a photo of that!

What grade is that? It turned very nicely in the other photos.So what next for our hapless hero…

The next day I rang the local metal place so I could start work on the replacement spacer, thankfully they had something I could use all I had to do was lighten my wallet a little further!

The trouble with hanging around on here is that, everyone is so capable and well equipped you kind of become imbued with a false sense that you are too. So instead of doing the sensible thing of asking them to cut it close to the size I needed I asked them for a 4 inch long piece, thinking the rest will come in handy for later...

It was only when I chucked it up that it became clear that my 3 ¾ by 4 inch piece that needed to be 3 ¼ by 1 inch might be a bit of a struggle.

View attachment 421035

Hmmm…

I dont know if theres a phrase for when the work you've got in the chuck is heavier than the chuck itself?View attachment 421037 View attachment 421038

Thanks 6ply I think my camera must have some sort of filter on for those photos! I forgot to ask what grade it was, at a guess I’d say en3 it didn’t go to tiny chips like free machining does. I should ask really it might be nice to weld with it at some point…What grade is that? It turned very nicely in the other photos.