mdr

Collector of welding machines

- Messages

- 346

- Location

- wye-on-earth

On this page...

https://www.mig-welding.co.uk/electrode-classification.htm

It mentions a couple of times...

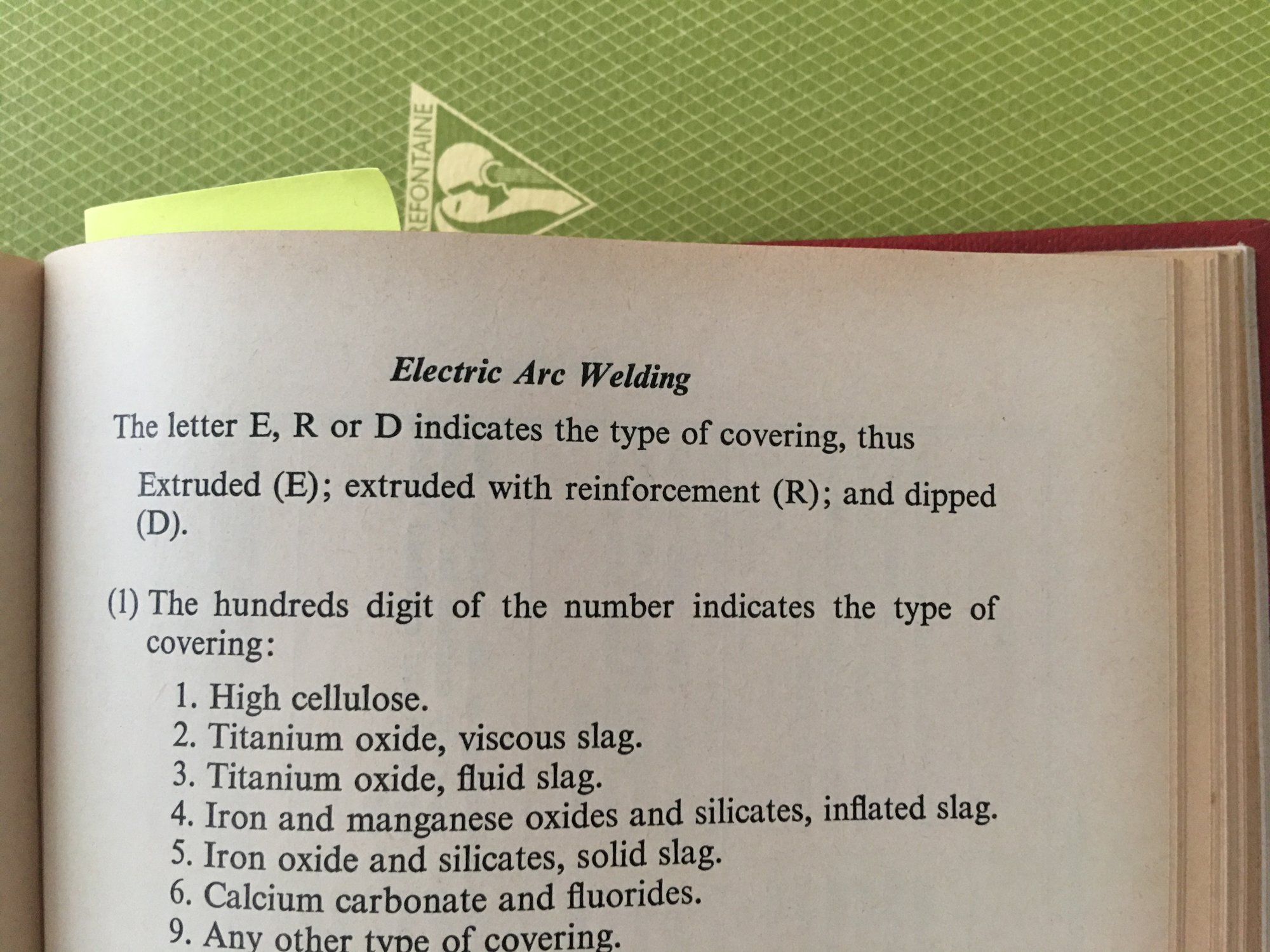

Could this be improved? Consulting The Science and Practice of Welding by A. C. Davies, fifth edition, it could be strongly argued that the E is for 'extruded'; in comparison to 'dipped' for example. Hence, the 'E' is in reference to the manufacturing process of the electrode.

https://www.mig-welding.co.uk/electrode-classification.htm

It mentions a couple of times...

E just means the electrode is for MMA welding and has a flux coating.

Could this be improved? Consulting The Science and Practice of Welding by A. C. Davies, fifth edition, it could be strongly argued that the E is for 'extruded'; in comparison to 'dipped' for example. Hence, the 'E' is in reference to the manufacturing process of the electrode.