Hello there i am trying to drill some holes on stainless (10mm thick). With an electric drill.

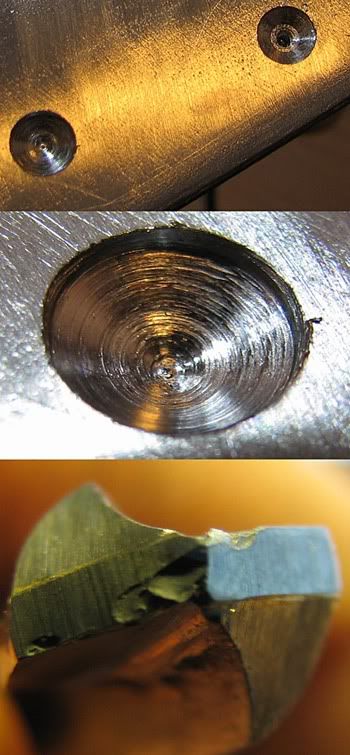

I made a pilot hole of 2mm with a cobalt drill kidna easy but in needs way much pressure so i snapped one at the base, and medium to high rpm (managed to make a continuous swarf once) didnt dull before it snaps though :P

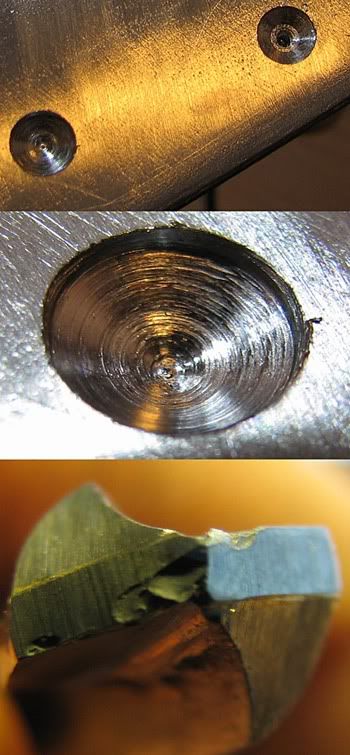

But i find out later that my tct drills (8mm) do not bite the metal too good, tried high-low speeds, much or little pressure. But all i end up is thick or dust like chips. And the drill edge broke at the edges of the pilot hole.

So what do you suggest ? Titanium or cobalt are any better ? Or is it a matter of technique mostly? Does hardened stainless is that all mighty ?

I made a pilot hole of 2mm with a cobalt drill kidna easy but in needs way much pressure so i snapped one at the base, and medium to high rpm (managed to make a continuous swarf once) didnt dull before it snaps though :P

But i find out later that my tct drills (8mm) do not bite the metal too good, tried high-low speeds, much or little pressure. But all i end up is thick or dust like chips. And the drill edge broke at the edges of the pilot hole.

So what do you suggest ? Titanium or cobalt are any better ? Or is it a matter of technique mostly? Does hardened stainless is that all mighty ?