- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Taper turning attachment.

- Thread starter ukracer

- Start date

8ob

Member

- Messages

- 14,370

- Location

- Nescient in the vale

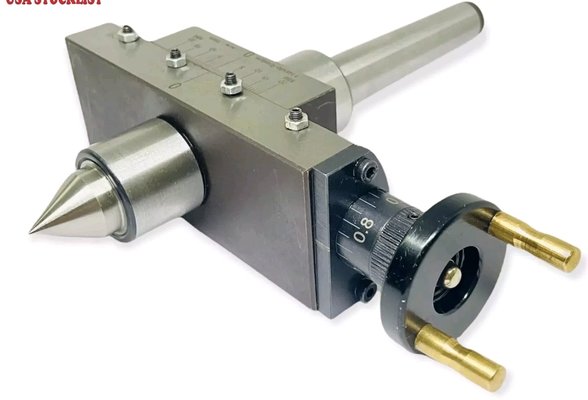

Has anyone used this type of taper turning attachment.

What were your findings about it?View attachment 462284

I like the look of that, how is the job driven when the center is trying to pull the workpiece sideways in the chuck?

Bob

Morrisman

Forum Supporter

- Messages

- 9,068

- Location

- Staffordshire, England

Kram

Member

- Messages

- 8,357

- Location

- Sussex

It is one of the simplest ways, however even simpler is that many tailstock have a screw to offset them, however then it needs to be reset afterwards which might not be a fun task.Has anyone used this type of taper turning attachment.

What were your findings about it?View attachment 462284

The best way is to mount an adjustable guide rail along the lathe bed, disengage the cross slide screw and attach the guide block to the cross slide, so that it follows the set taper.

I like the look of that, how is the job driven when the center is trying to pull the workpiece sideways in the chuck?

Bob

And this is good.

Agroshield

Member

- Messages

- 6,387

With that style, it is reasonably important to get it horizontal in use.

An alternative to that is to mount a standard boring head in the tailstock and then a rotating centre in the hole where the boring bar would go.

It is difficult to set that style to any known angle as the amount of offset depends on the length of the work (which is not obvious due to the centres in each end). Contrast to the standard type mentioned by kram above, where you can set it to (e.g. a Morse taper angle and it will cut that angle for any length of workpiece).

An alternative to that is to mount a standard boring head in the tailstock and then a rotating centre in the hole where the boring bar would go.

It is difficult to set that style to any known angle as the amount of offset depends on the length of the work (which is not obvious due to the centres in each end). Contrast to the standard type mentioned by kram above, where you can set it to (e.g. a Morse taper angle and it will cut that angle for any length of workpiece).

That's the real world application I was thinking. I wondered how people used to drive it without a morse taper at the head end.I like the look of that, how is the job driven when the center is trying to pull the workpiece sideways in the chuck?

Bob

I have been looking around for a taper turning attachment (conventional) that fits a specific lather.It is one of the simplest ways, however even simpler is that many tailstock have a screw to offset them, however then it needs to be reset afterwards which might not be a fun task.

The best way is to mount an adjustable guide rail along the lathe bed, disengage the cross slide screw and attach the guide block to the cross slide, so that it follows the set taper.

But a master. 2500 seems to be rare as hens teeth.

Agroshield

Member

- Messages

- 6,387

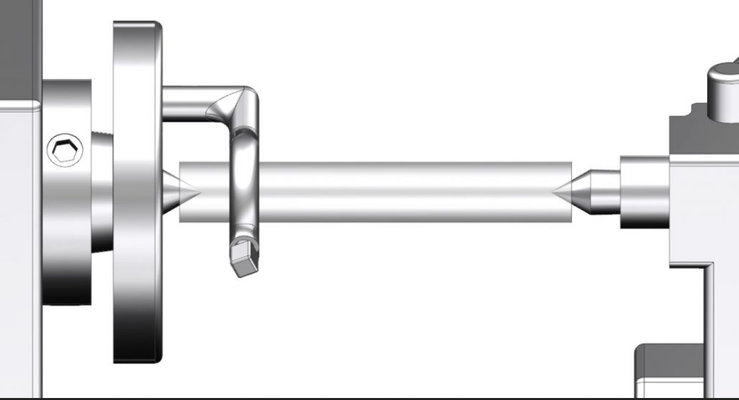

I wondered how people used to drive it without a Morse taper at the head end.

The attachment goes in the tailstock.

You could have almost nothing at all at the headstock end. Simplest is to grip an offcut of bar in a three jaw chuck and turn a 60 degree point on it using the top slide. It does not rotate relative to the workpiece, so does not need to be hardened and your chuck could be 1/4" out of true and it would not matter so long as you do not take the piece out of the chuck.

Edit, if you ever do find a taper turning attachment, it generally uses a special cross slide lead screw to the standard one. Make sure that leadscrew is included as it makes the attachment hard to use without it (some people dismantle the TT attachment off a machine they are scrapping, but do not add the x-slide screw into the bundle).

Kram

Member

- Messages

- 8,357

- Location

- Sussex

Linear guide rails and blocks are relatively cheap and would not be hard to fabricate mounts for it.I have been looking around for a taper turning attachment (conventional) that fits a specific lather.

But a master. 2500 seems to be rare as hens teeth.

Morrisman

Forum Supporter

- Messages

- 9,068

- Location

- Staffordshire, England

Simplest way to turn a fairly short taper is with the compound slide, if you don’t have a taper turning attachment of any sort. If you’re very careful and have a delicate hand you can also do long ones, by blending in several shorter sections.