shenion

Tool Pack Rat

- Messages

- 7,586

- Location

- Stone Mountain, GA USA

Ok, here is my vintage beast: http://shdesigns.org/Welding/airco.html

This is one of the 3 welders I got in my Ebay steal as mentioned in the "I wish I had 3 phase" thread. It is old and very low tech. So it should be easy to fix. Nothing burned inside. I have already replaced some leaking caps. Only other part likely to fail is a selenium rectifier. That can easily be replaced with modern diodes. Both fuses for the control circuits are still good, so looks like no shorted caps.

I will use this thread as I try to learn TIG welding and see if it still works. I think I have most of this beast figured out. There are a few switches I'm not sure about:

1. Start circuit in/out. The is already a HF start with start/off/continuous positions. I think the start circuit waits for a load then turns on the main contactor.

2. Metallic knife switch. I think this grounds the work side to the case for safety, open position is marked TIG.

3. Start adjustment: May be related to stick welding. I think it sets the initial current.

Came with a MIG wire feeder (feed motor is must weigh 5 pounds), a massive air-cooled stick electrode and a trashed spool gun. No TIG torch, hoses or gas/electrode plate.

I have a Weldcraft WP17 150A air-cooled torch with 25' lead on order. Should be fine for my uses, I did not want to mess with the water cooler. I need a 25' work lead and ground clamp. With the price of copper these days, it will probably be my biggest expense

I'll post pics as I get going. I think I can handle TIG as I have done some mild gas welding. But I bet I'll be baffled at some point.

This thing scares me. That 460A number on the dial is daunting. Amazingly, it goes down to 5 amps.

This is one of the 3 welders I got in my Ebay steal as mentioned in the "I wish I had 3 phase" thread. It is old and very low tech. So it should be easy to fix. Nothing burned inside. I have already replaced some leaking caps. Only other part likely to fail is a selenium rectifier. That can easily be replaced with modern diodes. Both fuses for the control circuits are still good, so looks like no shorted caps.

I will use this thread as I try to learn TIG welding and see if it still works. I think I have most of this beast figured out. There are a few switches I'm not sure about:

1. Start circuit in/out. The is already a HF start with start/off/continuous positions. I think the start circuit waits for a load then turns on the main contactor.

2. Metallic knife switch. I think this grounds the work side to the case for safety, open position is marked TIG.

3. Start adjustment: May be related to stick welding. I think it sets the initial current.

Came with a MIG wire feeder (feed motor is must weigh 5 pounds), a massive air-cooled stick electrode and a trashed spool gun. No TIG torch, hoses or gas/electrode plate.

I have a Weldcraft WP17 150A air-cooled torch with 25' lead on order. Should be fine for my uses, I did not want to mess with the water cooler. I need a 25' work lead and ground clamp. With the price of copper these days, it will probably be my biggest expense

I'll post pics as I get going. I think I can handle TIG as I have done some mild gas welding. But I bet I'll be baffled at some point.

This thing scares me. That 460A number on the dial is daunting. Amazingly, it goes down to 5 amps.

My caps work. Had sudden thought of Frankenstein movie, arcs buzzing all around and the Dr screaming "He's alive!"

My caps work. Had sudden thought of Frankenstein movie, arcs buzzing all around and the Dr screaming "He's alive!"

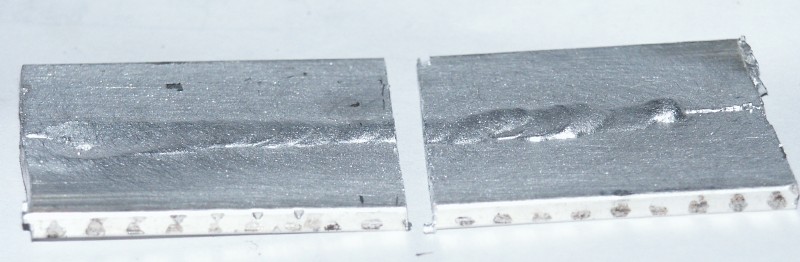

. I'm amazed how easy it was. Then again this is mild steel, not real thin or real thick.

. I'm amazed how easy it was. Then again this is mild steel, not real thin or real thick.