meweldyoutalk

Member

- Messages

- 13

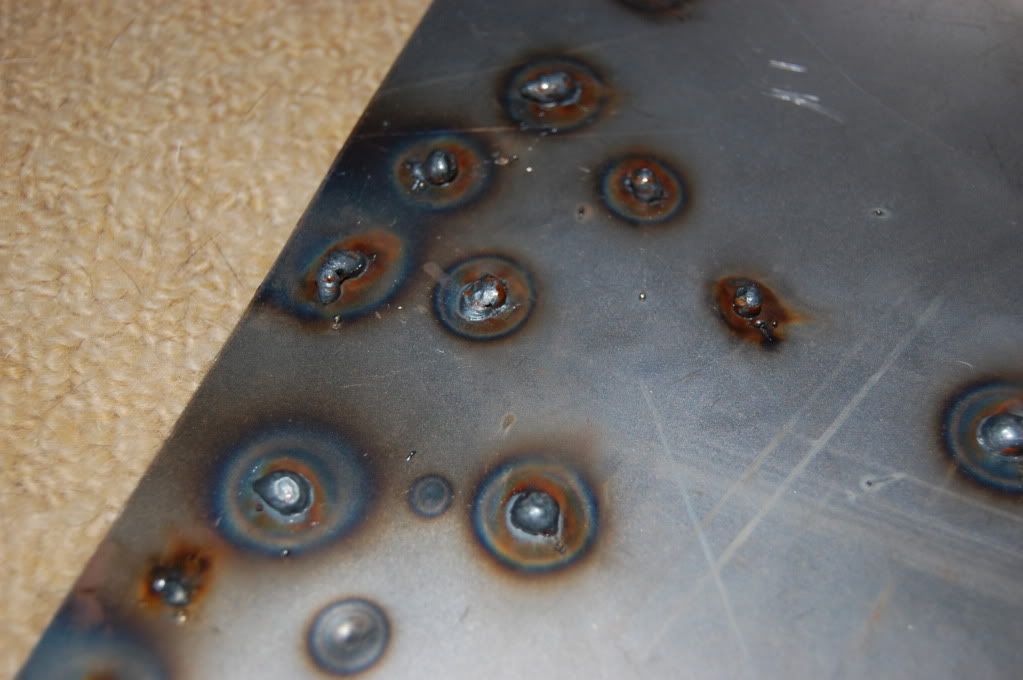

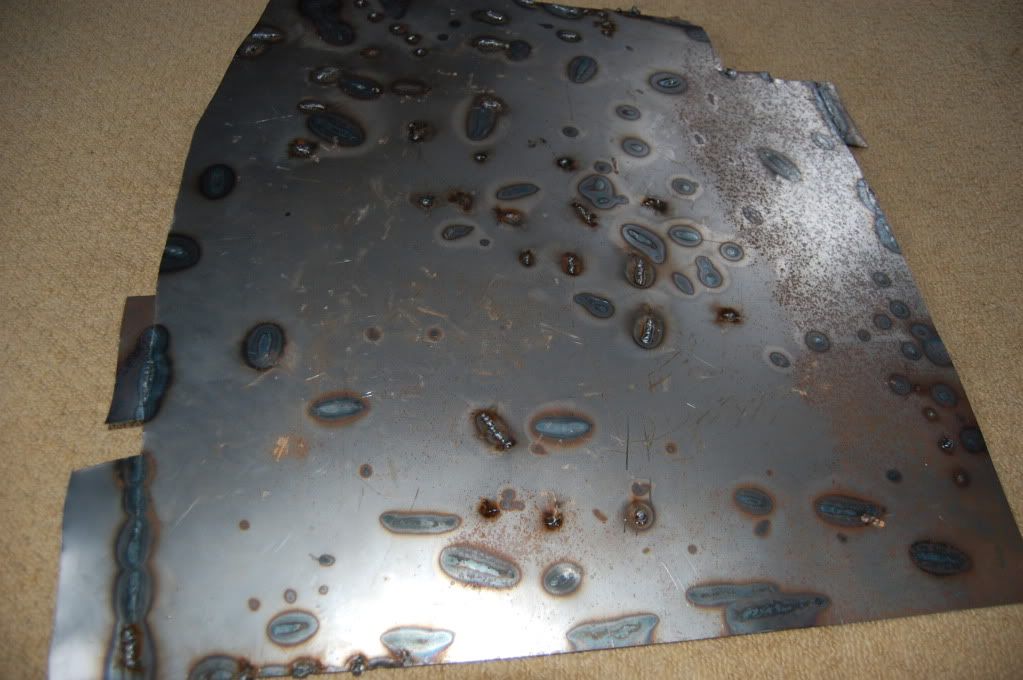

Ok, just learning to mig weld, but having a few problems, not sure if its my technique, setup or crap mig welder machine. Im trying to weld 1mm mild steel sheet, just trying to run straights line welds on the sheet but i seem to be getting no penetration thru to the other side, even on the highest setting, i have my flowmeter attached to my regulator and i have it showing 10litres per minute. im wondering if its because im using staright co2(pub gas). I am trying various wire speeds but just not getting the pebetration. My mig welder is a taskmaster 15/120. It has four power settings, even when i have it on 4 it will not penetrate to the other side. Im wondering if i have to go get myself a more expensive mig, i once read on here about cheap migs being no good. Or is it possbly because im using co2 which because it gives such a cold weld its stopping me getting good penetration, help????? If it is the mig are there any recommended that will weld 1mm steel sheet at say less than £200 or am i dreaming.

Ok, just learning to mig weld, but having a few problems, not sure if its my technique, setup or crap mig welder machine. Im trying to weld 1mm mild steel sheet, just trying to run straights line welds on the sheet but i seem to be getting no penetration thru to the other side, even on the highest setting, i have my flowmeter attached to my regulator and i have it showing 10litres per minute. im wondering if its because im using staright co2(pub gas). I am trying various wire speeds but just not getting the pebetration. My mig welder is a taskmaster 15/120. It has four power settings, even when i have it on 4 it will not penetrate to the other side. Im wondering if i have to go get myself a more expensive mig, i once read on here about cheap migs being no good. Or is it possbly because im using co2 which because it gives such a cold weld its stopping me getting good penetration, help????? If it is the mig are there any recommended that will weld 1mm steel sheet at say less than £200 or am i dreaming.