You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

My Old Landy

Engineering Mayhem

- Messages

- 3,506

- Location

- North Lincs

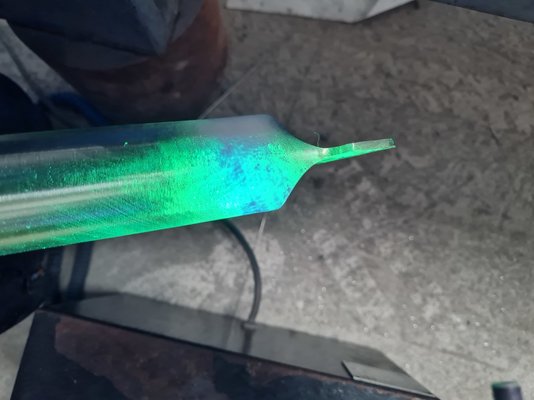

Steam punk maybe?Made a genuine light sabre.View attachment 369903

Let see if I can sell it to a cosplayer and get money out of scrap ?

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

Assembly. Now we need to add a little chaos from the connecting pipes. The engineer who designed all this (dissimilar equipment) threw me a pig. In the dew point sensor, compression fittings with a thread size of 11 mm * 1.25 and a non-standard tube are used. All this will have to be redone, for Festo quick pneumatic connections. Tig welding and angle grinders, as always, will help out.A frame for a technological module for preparing clean air with a screw compressor + an additional 500-liter receiver is mounted + a huge dehumidifier, then a refrigeration module + humidity sensor + carbon filter. All with automatic condensate removal valves. The output of compressed air from the compressor is 3/4", from the latest filter the output is 1/4" ... and again the entrance to a separate reactor with a diameter of 18 mmThe designer was an entertainer. In metal, it turned out intricately. Dimensions 2000*800, steel pipe 80*40*2.5, 40*40, 40*20 and 4 wheels with bearings, 500 kg load capacity each.

Remove grease from black scale with acetone, spray with 2K epoxy primer and then paint with 2K Raptor Polyurethane Paint. Applying paint with a roller turns out economically and a good appearance.

View attachment 369115 View attachment 369116 View attachment 369117

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

^^ A bit like a 3D jigsaw.

fbiiburton

Member

- Messages

- 101

Looks fantastic thatFinally got them in, and stupidly forgot to take finished photos...but I did get 1, lessons learned from this, need to quote more time, measure 35 not 30 times especially when they are so far away, pretty certain iv made a loss, but at least customer was happy.

View attachment 365936

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

View attachment 370092Been a busy 2 weeks but this will be the 4th shed I have done this year, each one better and more complicated than the last. I really love doing them!View attachment 370093View attachment 370093View attachment 370097View attachment 370096

It's a great feeling when you get a big etrection like that .

It's a great feeling when you get a big etrection like that .One that you build up yourself and everything fits without alterations.

Was it a kit made to measure or one you made & welded up yourself & bolted up .

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

Where abouts are you based in Cumbria? Are you guys doing ce marking on structural stuff?View attachment 370092Been a busy 2 weeks but this will be the 4th shed I have done this year, each one better and more complicated than the last. I really love doing them!View attachment 370093View attachment 370093View attachment 370097View attachment 370096

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

Made a small rack to hold the longer bits or stainless studding as I kept losing bits amongst the bzp stuff..!

Anything under 250mm ish goes in the drawer of that size stainless bolts.

Anything under 250mm ish goes in the drawer of that size stainless bolts.

Morris

Forum Supporter

- Messages

- 2,212

- Location

- Northamptonshire.

I needed a gear lever for Wifey's Ford Pop project so a quick rummage saw a piece of stainless in the chuck and machined up. I don't have a taper turning attachment so the taper was done with the compound slide offset to 0.6 degrees. Needless to say this was a long job. There was then the long slow job of polishing it (I don't have a polisher).

The bottom is drilled to suit the stub on my home-made shift mechanism. It all works very nicely, just need a knob (fnar-fnar) for it now.

The bottom is drilled to suit the stub on my home-made shift mechanism. It all works very nicely, just need a knob (fnar-fnar) for it now.

- Messages

- 13,490

- Location

- England

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Nice work, that will breath a bit betterSomething different this week.

Wasn't a lot left underneath.

Yes. They did run the membrane over the joists. Stayed damp all year.

View attachment 370237 View attachment 370238 View attachment 370239 View attachment 370240 View attachment 370241 View attachment 370242 View attachment 370243 View attachment 370244 View attachment 370245

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Lifted it a couple of inches above the wall to allow airflow underneath.Nice work, that will breath a bit better

Same with the step. Supports touching slabs have plastic underneath. Should last well.

One I’ve made from scratch, just a little one compared to the last ones thou, I done that shed and its lean too to the right.... theirs now talk of a lean too left as well

It's a great feeling when you get a big etrection like that .

One that you build up yourself and everything fits without alterations.

Was it a kit made to measure or one you made & welded up yourself & bolted up .

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex