You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

8ob

Member

- Messages

- 14,286

- Location

- Nescient in the vale

This is where I had got to yesterday with my new column for the linisher.

View attachment 169230

Thought I had it done today, minus paint.

View attachment 169231

Nope. To front heavy when folded forwards into the vertical position, so I bolted a couple of bits of angle to the base. Then found that there isn't enough friction in the hinge to keep it in the vertical position due to the weight, so had to start bodging a stop of some kind.

I've pretty much got it but I'm not very happy with how it looks, might attach it with the grinder at some point. But, it'll work. Didn't get a pic of it finished as the evening was pressing on and the better half was waiting for me to have dinner.

Aha! A fellow user of seasoned steel

Bob

mpats

Member

- Messages

- 1,177

Yup, use what I have, mainly for free. It's my favorite price!Aha! A fellow user of seasoned steel

Bob

Parm

Respect The Sound System

- Messages

- 17,894

- Location

- Towcester

Aha! A fellow user of seasoned steel

Bob

I’m going to borrow that expression, sounds much better rusty old metal

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

First thing this morning I fitted the CNC control into the housing and plugged in the cables, it will be a while before I can do the actual retrofit as I will be needing the lathe over the next few weeks and I will be too busy on the latest Cheetah Catamaran to do it.

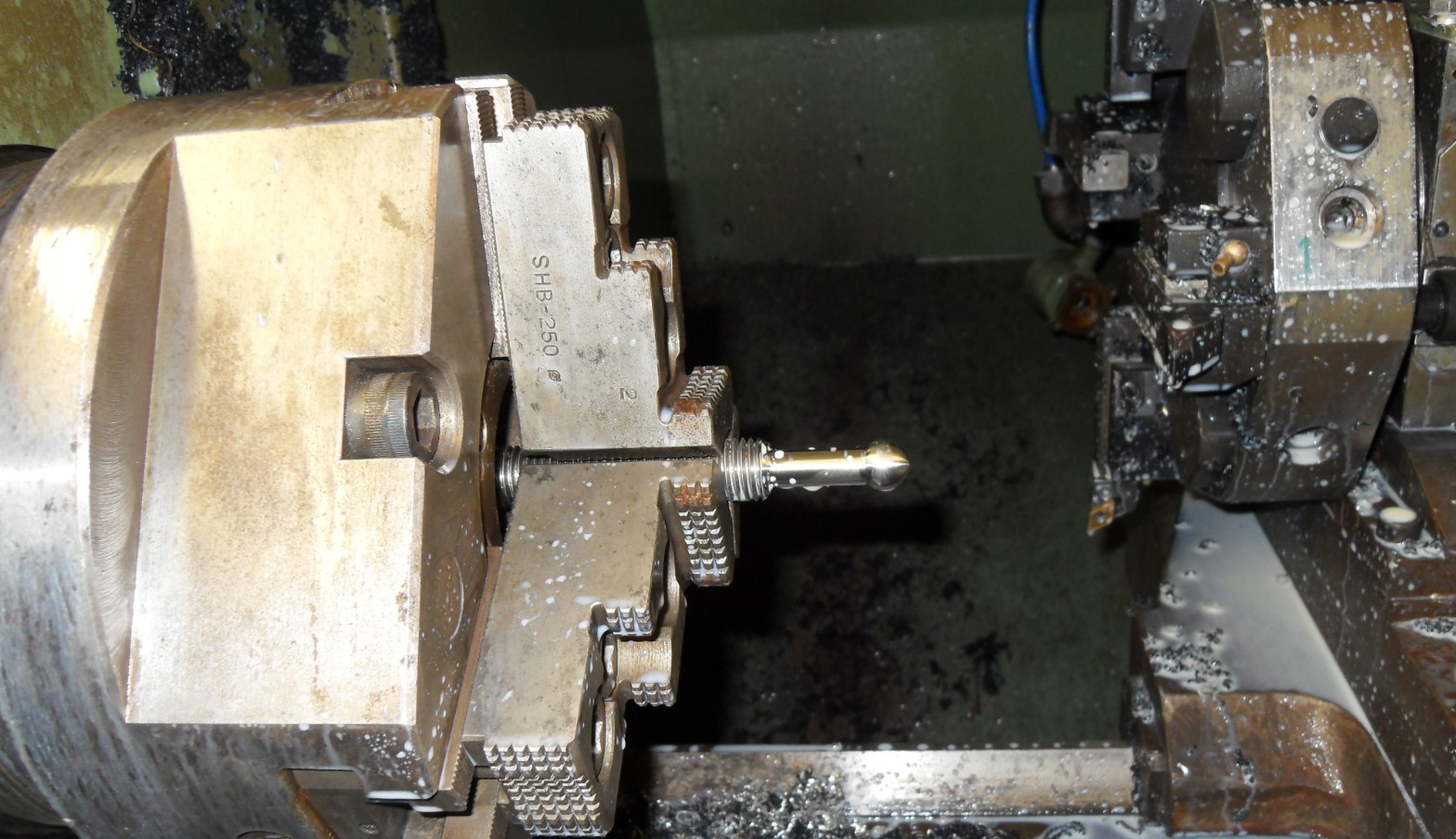

I then used the lathe to make 4 crab spikes.

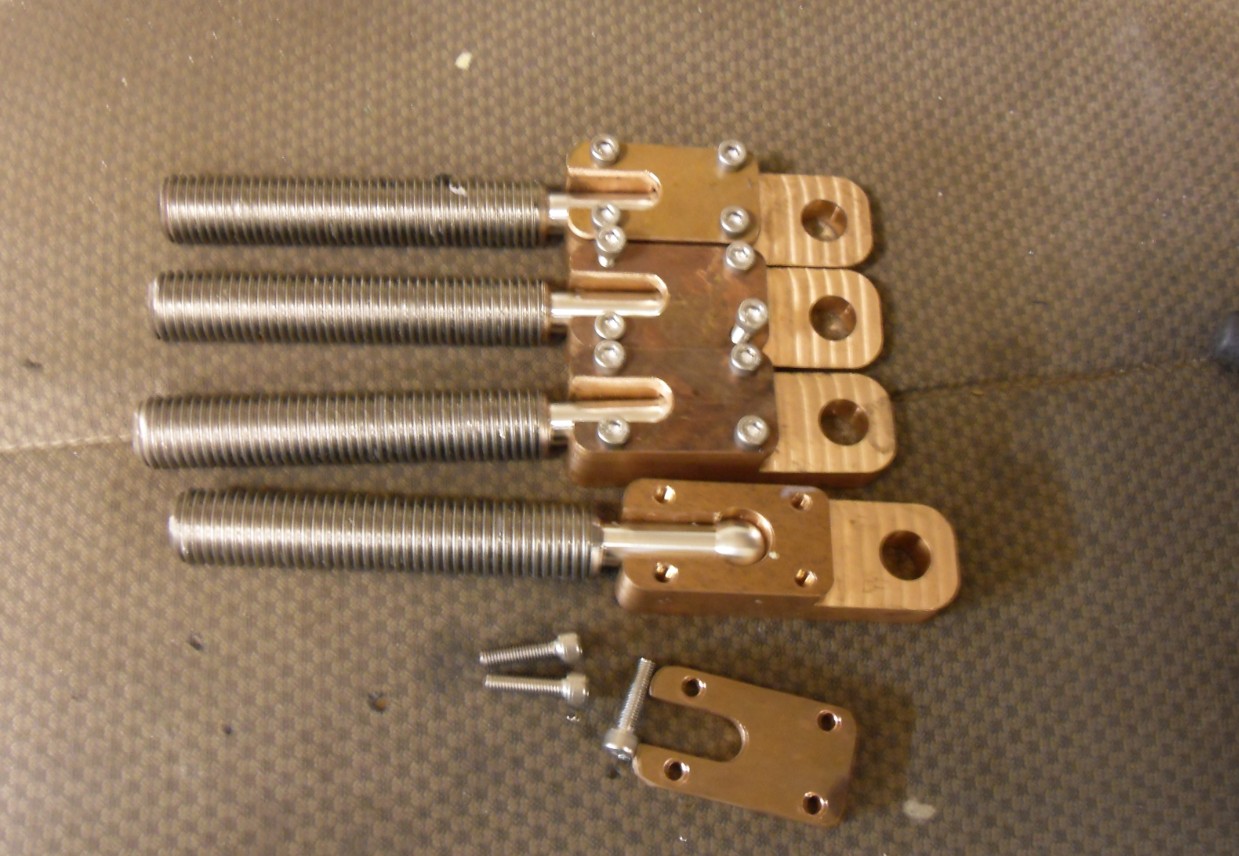

Went away down to a boat to fix a roller and replace cables on the throttle and gear levers and when I got back about 4hrs later I made the rod ends for the steering of the latest Cat from M20 316 screwed rod.

Video of the lathe doing the rod ends.

I then used the lathe to make 4 crab spikes.

Went away down to a boat to fix a roller and replace cables on the throttle and gear levers and when I got back about 4hrs later I made the rod ends for the steering of the latest Cat from M20 316 screwed rod.

Video of the lathe doing the rod ends.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Cant take full credit for them as I saw them on a boat and just improved (hopefully) a bit on the design.Love those rod ends for the steering Hood. Very neat

- Messages

- 6,227

- Location

- SW Scotland

Socket heads are a nice touch. Something to get the mole grips onto when you need itCant take full credit for them as I saw them on a boat and just improved (hopefully) a bit on the design.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Was going to use countersunk but the hex in these Chinese stainless screws are so soft it often does require mole gripsSocket heads are a nice touch. Something to get the mole grips onto when you need it

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

The originals actually just had set screws holding the rod in, I wasn't keen on that although they do seem to be secure enough I wouldn't want a boat I had fitted out suddenly losing steering when it was coming into the harbour or similar.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

That didn't really make much sense or rather didn't illustrate how they are used. You pick up a crap and allow it to grab the spike with its claw (tapered to accommodate all sizes) then you touch the joint with a knife and it disables the claw.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I think it is basically the same as you only cut when they are gripping and it only takes a touch with the knife. If you try and cut or stab when there is no tension then they usually cast the claw or bleed to death.You cut the opening joint, over this way they do the closing joint. Poke the hinged claw into a small hole, gentle pressure so the claw opens and then nick the joint. Slightly more secure as if the claw get wedged open it can't be closed.

cheb

Member

- Messages

- 3,813

- Location

- Ostdeutschland

It's a fiddly process getting the pressure right. Once cut they go straight into a vivier tank or back into the sea in a box. Most from here goes down to Spain in vivier lorries so there's a lot more opportunity for the claws to be knocked open.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Same here, either into tanks or boxes with deck hose running through, used to be on a boat and we would get 25-30 boxes a day then the clammers came round from the West. First day we had 15 boxes of good and 10 boxes with holes in their backs, next day we had about 10 boxes total then after that we were lucky to get a couple of boxes. Twenty years on and things are improving but still not up to the catches of the past and that is with 3 or 4 times the creels we used to work.

Pete.

Forum Supporter

- Messages

- 15,047

- Location

- Kent, UK

Geo water swivel shaft, made a couple. Dropped them off at the hard chrome platers today

Long series clarkson autolock came in handy View attachment 169234View attachment 169235

LH thread. They love doing that so you have to buy their expensive rods. Platypus ground anchors are the same.