You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

He's on very safe ground if he's driven a good 75 . . . my TS was wonderfully neutral, nicely balanced when you did get the tail sliding, or even when you didn't actually intend to when you found the diesel patch on a wet Leeds roundaboutMy Alfa loving mate was taking the **** out of me last night for owning 5 Vauxhall's (a diesel Zafira cured me totally of that) he has a few 75's!

I'm gonna have me some fun next time I see him

Another one of the cars that if I had enough space, I'd have again.

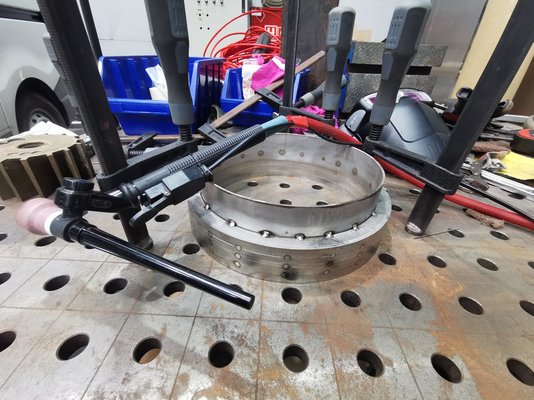

I made some holes in a bit 2mm steel, cut a corner of a wall box, then glued them together with the TIG welder -

Given I can't even remember the last time I used the TIG welder (obviously since the last time I arc welded anything, as the TIG torch was attached!), my welding helmet is playing up (12 year old Optrel Satellite that I think the batteries are finally dying on, as the auto darkening is quite hit and miss), and the thinnest welding gloves I could find were still far too thick and stiff that I could hardly feel the torch let along the rod, I think I done well to only blow a few holes in the metal, and only need to regrind the tungsten twice.

Given I can't even remember the last time I used the TIG welder (obviously since the last time I arc welded anything, as the TIG torch was attached!), my welding helmet is playing up (12 year old Optrel Satellite that I think the batteries are finally dying on, as the auto darkening is quite hit and miss), and the thinnest welding gloves I could find were still far too thick and stiff that I could hardly feel the torch let along the rod, I think I done well to only blow a few holes in the metal, and only need to regrind the tungsten twice.

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Made a lowering/rising table for the laser, well basically I just bolted some MDF to an adjustable lab stand and made the feet adjustable for levelling, I was going to make one but they are only £25 for a nicely made aluminium one so cheaper than I could make.

It means now I can raise or lower the table and have the camera work well no matter what I have on the table as the top of the part is always at the cameras calibrated height, also means I never have to adjust the laser height to focus it

It means now I can raise or lower the table and have the camera work well no matter what I have on the table as the top of the part is always at the cameras calibrated height, also means I never have to adjust the laser height to focus it

MattF

Forum Supporter

- Messages

- 18,537

- Location

- South Yorkshire

but they are only £25 for a nicely made aluminium one

Link?

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Link?

VEVOR Aluminum Lab Jack Stand 8'' Heavy Duty 60-310mm Laboratory Scissor Stand 687117081797 | eBay

Find many great new & used options and get the best deals for VEVOR Aluminum Lab Jack Stand 8'' Heavy Duty 60-310mm Laboratory Scissor Stand at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Just tested out the lowering table/camera placement setup and it is spot on.

Placed a top clamp end on so 125mm from the base board, lowered the board and placed my logo in position on the computer screen.

Image on computer screen showing logo has etched exactly under the placement of the screen logo.

And the result.

Placed a top clamp end on so 125mm from the base board, lowered the board and placed my logo in position on the computer screen.

Image on computer screen showing logo has etched exactly under the placement of the screen logo.

And the result.

northwest

Searching for the Holy Grail.........

- Messages

- 6,692

- Location

- Manchester UK

Well, I got stuck in, had my Weetabix and made a start, Heavy Engineering today, first off, using a 3mm boring bar to clean up a pressure cylinder valve unit:

Then I got stuck in to the tough stuff, 1.6mm Titanium (after turning):

No wonder I need glasses.

Then I finished an **** of a job, slit a 20mm Titanium plate up the middle. Going to look for a GOOD dust mask in a minute as the dust and fumes were awful and I have more to do tomorrow. At first I thought "crikey, it is going through this quick" as the angle grinder sank downover, until I realised it was just eating disks:

Needed the Fein 240 volt tool to finish off as the battery gave in on the heavy Dewalt:

Then I got stuck in to the tough stuff, 1.6mm Titanium (after turning):

No wonder I need glasses.

Then I finished an **** of a job, slit a 20mm Titanium plate up the middle. Going to look for a GOOD dust mask in a minute as the dust and fumes were awful and I have more to do tomorrow. At first I thought "crikey, it is going through this quick" as the angle grinder sank downover, until I realised it was just eating disks:

Needed the Fein 240 volt tool to finish off as the battery gave in on the heavy Dewalt:

What is it going to be?Well, I got stuck in, had my Weetabix and made a start, Heavy Engineering today, first off, using a 3mm boring bar to clean up a pressure cylinder valve unit:

View attachment 410964

Then I got stuck in to the tough stuff, 1.6mm Titanium (after turning):

View attachment 410965

No wonder I need glasses.

Then I finished an **** of a job, slit a 20mm Titanium plate up the middle. Going to look for a GOOD dust mask in a minute as the dust and fumes were awful and I have more to do tomorrow. At first I thought "crikey, it is going through this quick" as the angle grinder sank downover, until I realised it was just eating disks:

View attachment 410968

Needed the Fein 240 volt tool to finish off as the battery gave in on the heavy Dewalt:

View attachment 410969

northwest

Searching for the Holy Grail.........

- Messages

- 6,692

- Location

- Manchester UK

What is it going to be?

It is, or rather, they are (I made ten) AR15 firing pins.

The titanium plate, or rather some of the titanium plate I hope to turn into Marlin lifters, the part that lifts the cartridge from the tubular magazine to the breech. We will see, it is tough stuff and not easy on the tooling.

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

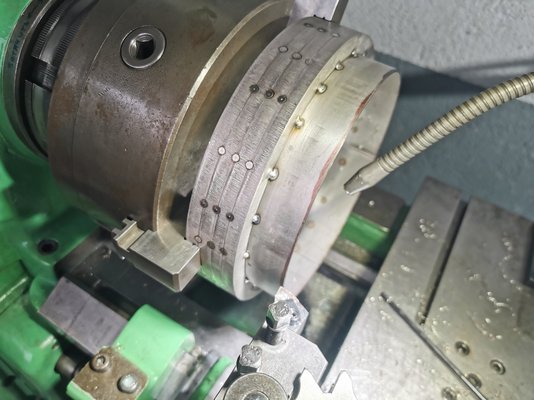

Parts #2Matryoshka principle: reworking the valve, the inner diameter should smoothly change from 225 to 204 mm. Type-setting insert 70 mm high, made of 10 mm thick plates and a pipe section. TIG welding, angle grinder, lathe and laser cutting. Parts #1.

View attachment 411060 View attachment 411061 View attachment 411062 View attachment 411063 View attachment 411064

northwest

Searching for the Holy Grail.........

- Messages

- 6,692

- Location

- Manchester UK

Made a few rests forthe benches today. Threatened to do it a while back but I needed something "suitable" which turned out to be the bottom leg for adustable scaffoldi ng. I know, but these guys could break a cannonball!

Then, continuing my mission of trying to actually finish some jobs I determined to finish cutting the large bit of rail track into two smaller bits. This is where it went a bit south. My pal realised something was up when all the sparks were going skywards, he came over explaining the grinder should be going the other way, go on then, have a go:

As yiu can see, he had to press the trigger with his thumb, it really could do with being turned 180 degrees to have the trigger in the proper orientation. If anyone has any suggestions I would welcome them. Meanwhile, finished the job so result anyway.

Then, continuing my mission of trying to actually finish some jobs I determined to finish cutting the large bit of rail track into two smaller bits. This is where it went a bit south. My pal realised something was up when all the sparks were going skywards, he came over explaining the grinder should be going the other way, go on then, have a go:

As yiu can see, he had to press the trigger with his thumb, it really could do with being turned 180 degrees to have the trigger in the proper orientation. If anyone has any suggestions I would welcome them. Meanwhile, finished the job so result anyway.

selectedgrub

Member

- Messages

- 3,550

- Location

- New Zealand

Do you live in Alaska.

That's alot of work to "make a start on this tonight"