You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Battery boxWhat is it?

Kram

Member

- Messages

- 8,458

- Location

- Sussex

While messing about with melter I did a round tuit on lathe and made up 6 pins for dinse 10-25 plugs to be brazed on. Then stuck the 3 I can find with silver solder.

I dont have any original 10-25's so not sure what size the pin should be turned to, 4 or 5mm square is probably ok.

I dont have any original 10-25's so not sure what size the pin should be turned to, 4 or 5mm square is probably ok.

Coat rack finished, apart from making 20 odd hooks, that’s the last time I’ll see it now.

View attachment 334067

Spot the mistake?

I rather like that. Simple and effective.

Munkul

Jack of some trades, Master of none

- Messages

- 7,744

- Location

- Cumbria

Good effort, I bet the cost of material was similar to buying ones off the shelfWhile messing about with melter I did a round tuit on lathe and made up 6 pins for dinse 10-25 plugs to be brazed on. Then stuck the 3 I can find with silver solder.

I dont have any original 10-25's so not sure what size the pin should be turned to, 4 or 5mm square is probably ok.

prepman

Forum Supporter

- Messages

- 2,757

- Location

- Gwynedd UK

One legged races?I only ever see single shoes at the side of the road.

God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Cuthy246

Member

- Messages

- 924

- Location

- Scotland, Highlands

Don't weld it on with the magnet in placeNow that the crap weather has passed I was able to do a bit. Got the shoots done. Made a start on the handles.

View attachment 334330 View attachment 334331 View attachment 334332

are all the chamfers done by hand? The way everything lines up next to that g clamp is almost pornographic

are all the chamfers done by hand? The way everything lines up next to that g clamp is almost pornographicGod mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Magnet is just to hold it in place so I can step back to get a visual. Everything is done by hand. All I use is a 0.8 cutting disc. Flap wheel and files.Don't weld it on with the magnet in placeare all the chamfers done by hand? The way everything lines up next to that g clamp is almost pornographic

Cuthy246

Member

- Messages

- 924

- Location

- Scotland, Highlands

Top notch work as alwaysMagnet is just to hold it in place so I can step back to get a visual. Everything is done by hand. All I use is a 0.8 cutting disc. Flap wheel and files.

God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Thanks cuthy.Top notch work as always

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

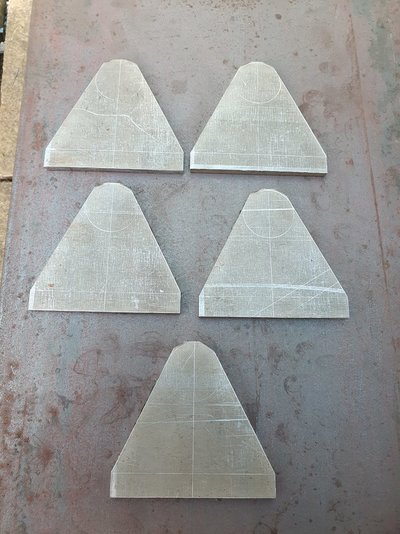

Today I made a set of forms for making 100mm long louvers.

All made out of scrap using various grinders.

Started by cutting a bit of 10mm plate to size with a 4.5 inch grinder then shaping it with a flap discs.

Then squared an edge on an off-cut of 25mm plate, marked the rough shape and made a few cuts with a slitting disc.

Ground the middle out with a 4 inch and did the corners with a 2 inch grinder

FInished off the shaping with a die grinder.

Then tack welded a short piece of 5mm x 25 flat to close off the end of the die. This would probably be better if it was 25 square bar but it will do for a test.

And tacked a bit of heavy flat bar to the other form.

Cut a slot in a bit of scrap and tried it out.

I need to be a bit more particular in cutting the slot and clean up the sharp edges but it seems to work ok.

All made out of scrap using various grinders.

Started by cutting a bit of 10mm plate to size with a 4.5 inch grinder then shaping it with a flap discs.

Then squared an edge on an off-cut of 25mm plate, marked the rough shape and made a few cuts with a slitting disc.

Ground the middle out with a 4 inch and did the corners with a 2 inch grinder

FInished off the shaping with a die grinder.

Then tack welded a short piece of 5mm x 25 flat to close off the end of the die. This would probably be better if it was 25 square bar but it will do for a test.

And tacked a bit of heavy flat bar to the other form.

Cut a slot in a bit of scrap and tried it out.

I need to be a bit more particular in cutting the slot and clean up the sharp edges but it seems to work ok.

Edward Teach

pre-moderated

- Messages

- 992

- Location

- South West England

I don't comment often on this page,Today I made a set of forms for making 100mm long louvers.

All made out of scrap using various grinders.

Started by cutting a bit of 10mm plate to size with a 4.5 inch grinder then shaping it with a flap discs.

View attachment 334363

Then squared an edge on an off-cut of 25mm plate, marked the rough shape and made a few cuts with a slitting disc.

View attachment 334364

Ground the middle out with a 4 inch and did the corners with a 2 inch grinder

View attachment 334366

FInished off the shaping with a die grinder.

View attachment 334367

Then tack welded a short piece of 5mm x 25 flat to close off the end of the die. This would probably be better if it was 25 square bar but it will do for a test.

View attachment 334368

And tacked a bit of heavy flat bar to the other form.

View attachment 334369

Cut a slot in a bit of scrap and tried it out.

View attachment 334372

I need to be a bit more particular in cutting the slot and clean up the sharp edges but it seems to work ok.

View attachment 334373

But this is worth commenting on,

Brilliant, time consuming, top work.

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

I don't comment often on this page,

But this is worth commenting on,

Brilliant, time consuming, top work.

Thanks @Edward Teach it took a good two hours to make.

It helped that I have more grinders than any sensible person should ever need but sometimes having the right tool really helps.

Now I'm not saying a grinder is the ideal tool for a job like this but it's surprising what you can make with simple tools if you put your mind to it.

God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I have a job coming up that I need 4 accurate holes bored into. The Chiron does a reasonable job at interpolating circles but it is 35 years old and probably had a hard life for at least half of that and it has a wee bit of backlash, about 0.02mm on the X and a bit less on the Y.

I needed a boring head but had given my good ones away years ago thinking I would never need them but I did have one for the Beaver NC5 that looks to be a home made one, a decent one though and it had been properly hardened.

but I did have one for the Beaver NC5 that looks to be a home made one, a decent one though and it had been properly hardened.

So strip it down and into the Triumph.

Turned it down to 25mm Dia.

Popped in the Chiron and milled a flat.

Built it back up

Then tried it out, finish was decent and after a bit of tweaking it was on size.

I needed a boring head but had given my good ones away years ago thinking I would never need them

but I did have one for the Beaver NC5 that looks to be a home made one, a decent one though and it had been properly hardened.

but I did have one for the Beaver NC5 that looks to be a home made one, a decent one though and it had been properly hardened.So strip it down and into the Triumph.

Turned it down to 25mm Dia.

Popped in the Chiron and milled a flat.

Built it back up

Then tried it out, finish was decent and after a bit of tweaking it was on size.