Hi all,

I’m new here and would really appreciate some urgent advice regarding a residential weld on my project.

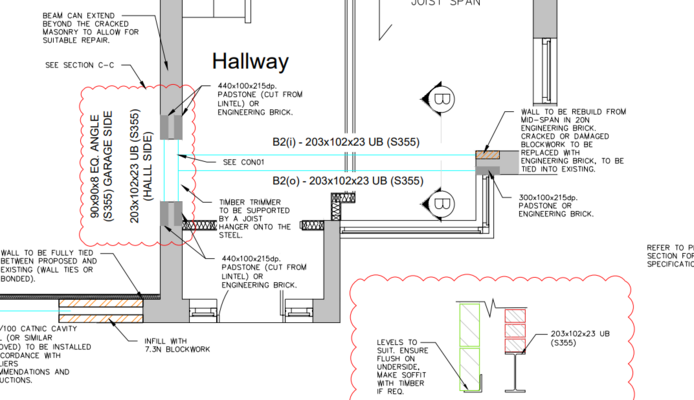

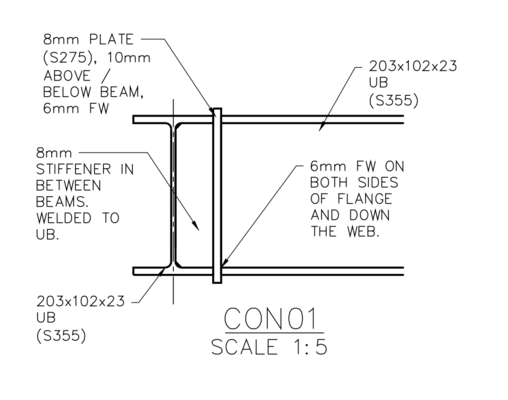

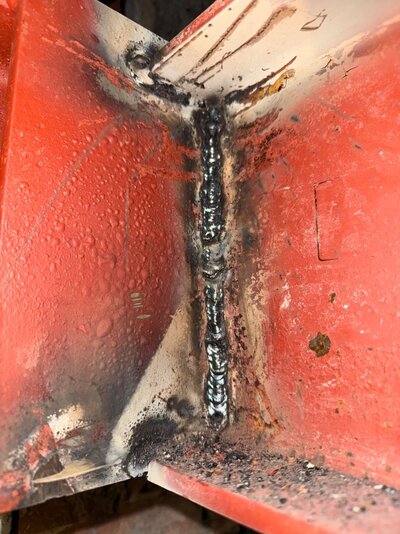

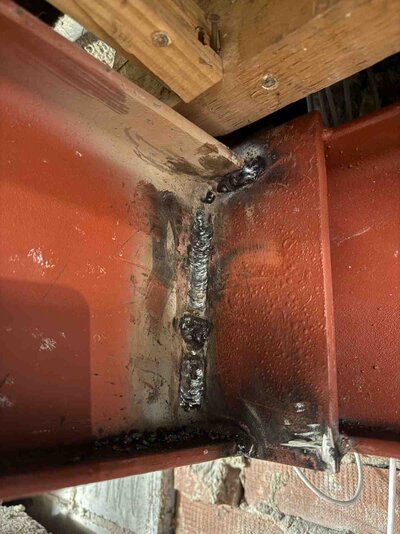

Our builder, who has been good up to now - brought in a welder today to join two steel beams (one supporting the inner leaf and one supporting the outer leaf) onto another steel using a welded plate. I’ve attached some photos along with the structural engineer’s details for reference.

Unfortunately, I wasn’t home when the welder arrived; otherwise, I would have asked questions on the spot. Now that I’ve seen it, I’m concerned about the quality of the work and its structural integrity - although I’m not a welding expert, something doesn’t look right to me. The Acrow props are still in place.

My main concerns are:

Before I push this further, I’d really value the opinion of people who actually know what they’re looking at. Do I have legitimate cause for concern here?

Thanks in advance - any guidance would be hugely appreciated

I’m new here and would really appreciate some urgent advice regarding a residential weld on my project.

Our builder, who has been good up to now - brought in a welder today to join two steel beams (one supporting the inner leaf and one supporting the outer leaf) onto another steel using a welded plate. I’ve attached some photos along with the structural engineer’s details for reference.

Unfortunately, I wasn’t home when the welder arrived; otherwise, I would have asked questions on the spot. Now that I’ve seen it, I’m concerned about the quality of the work and its structural integrity - although I’m not a welding expert, something doesn’t look right to me. The Acrow props are still in place.

My main concerns are:

- The welder hasn’t ground the primer at all. I’m worried about how well a fillet weld can bond through primer, and whether porosity could be an issue now that the paint has been burnt off instead of properly cleaned.

- Some welds appear to be “sitting on top” of the steel rather than blending into it, which makes me question the fusion.

- There’s a huge amount of spatter. It almost looks like someone practising, which doesn’t fill me with confidence about the welder’s competence.

- The structural engineer specified 6mm fillet welds, but what’s been done looks very inconsistent.

Before I push this further, I’d really value the opinion of people who actually know what they’re looking at. Do I have legitimate cause for concern here?

Thanks in advance - any guidance would be hugely appreciated

-

Screenshot 2025-12-08 at 22.10.05.png188.6 KB · Views: 248

Screenshot 2025-12-08 at 22.10.05.png188.6 KB · Views: 248 -

Screenshot 2025-12-08 at 21.46.21.png102.9 KB · Views: 225

Screenshot 2025-12-08 at 21.46.21.png102.9 KB · Views: 225 -

IMG_6979.JPG257.5 KB · Views: 193

IMG_6979.JPG257.5 KB · Views: 193 -

IMG_6978.JPG157.3 KB · Views: 254

IMG_6978.JPG157.3 KB · Views: 254 -

IMG_6967.JPG106.6 KB · Views: 275

IMG_6967.JPG106.6 KB · Views: 275 -

IMG_6966.JPG190.8 KB · Views: 284

IMG_6966.JPG190.8 KB · Views: 284 -

IMG_6965.JPG182.2 KB · Views: 283

IMG_6965.JPG182.2 KB · Views: 283 -

IMG_6964.JPG99 KB · Views: 276

IMG_6964.JPG99 KB · Views: 276 -

IMG_6968.JPG155.8 KB · Views: 267

IMG_6968.JPG155.8 KB · Views: 267 -

IMG_6969.JPG139.1 KB · Views: 264

IMG_6969.JPG139.1 KB · Views: 264