paulmitchell1984

Member

- Messages

- 814

- Location

- Leeds

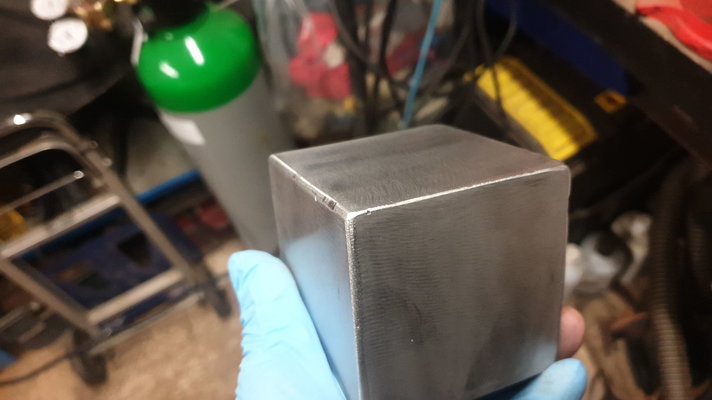

Hi guys

Been tinkering lately with tig (only got it last week)

Got board of doing flat plate straight runs so I made a box...

It's nothing compared to the masterpieces on here but I'm pretty chuffed with it.

Still need to massively improve on tacking up iv been trying to get the 2 pieces to just blend with no filler bit not proving successful at minute.

Been tinkering lately with tig (only got it last week)

Got board of doing flat plate straight runs so I made a box...

It's nothing compared to the masterpieces on here but I'm pretty chuffed with it.

Still need to massively improve on tacking up iv been trying to get the 2 pieces to just blend with no filler bit not proving successful at minute.