TR6 Rebuild

New Member

- Messages

- 21

If anyone has got any ideas why my trusty Murex Tradesmig 135 has stopped working I would really appreciate it.

I've had this machine for years, bought it second hand and not used it in a while.

Everything seemed fine, got gas and wire feed, can hear the relay kicking in on trigger but I get a spark but no ARC.

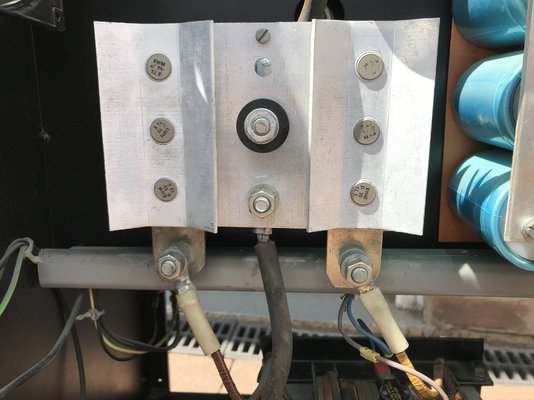

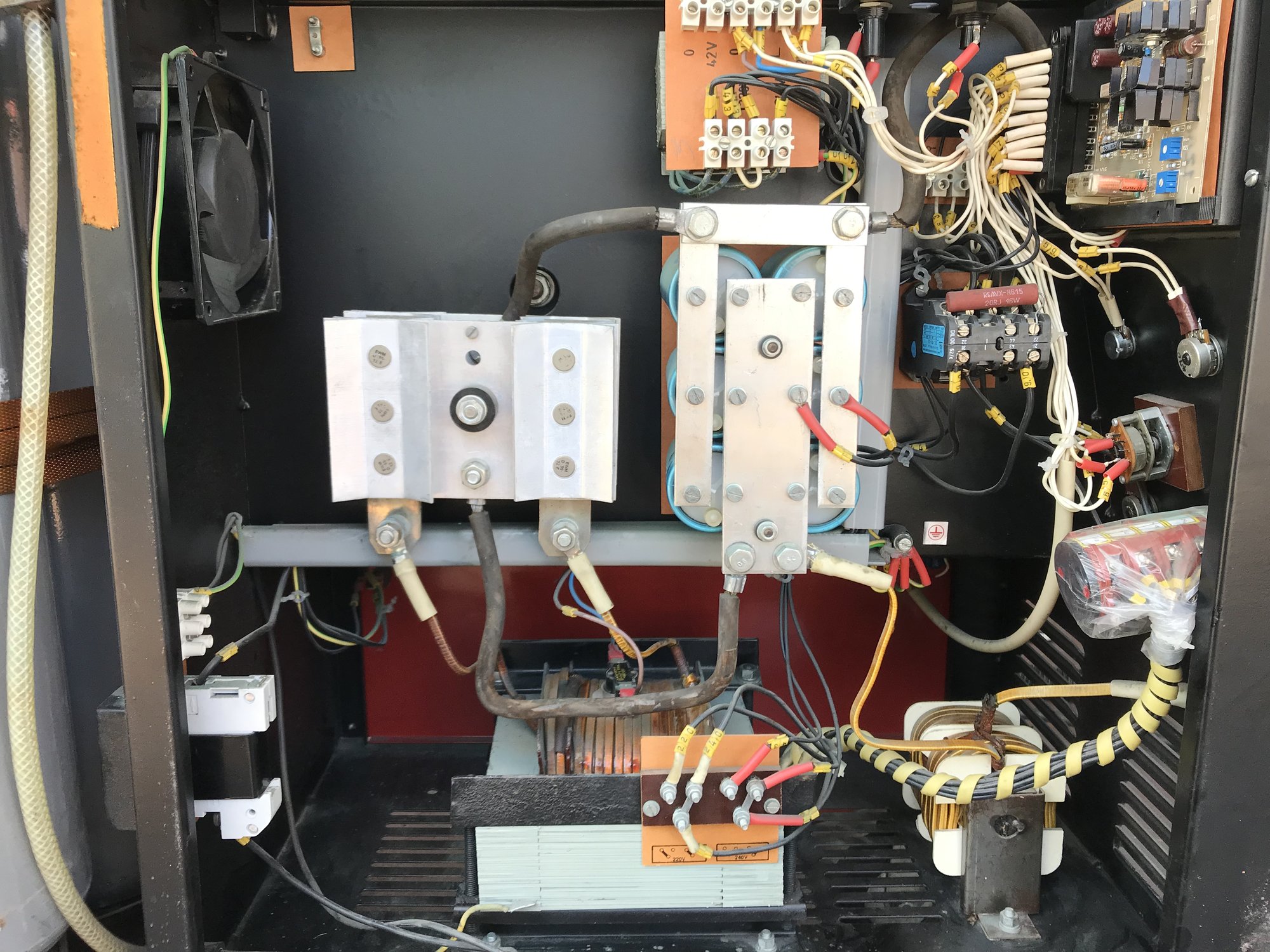

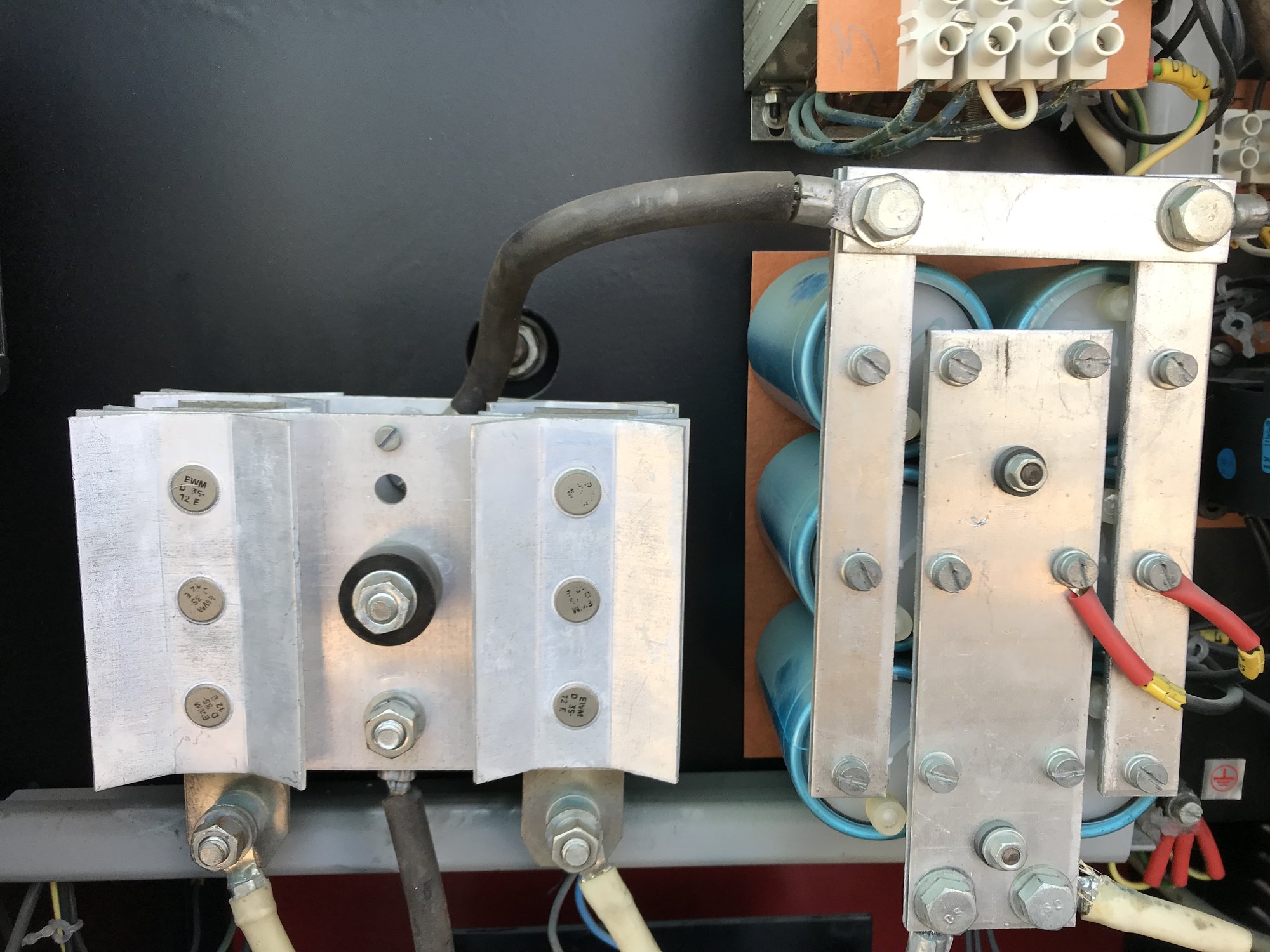

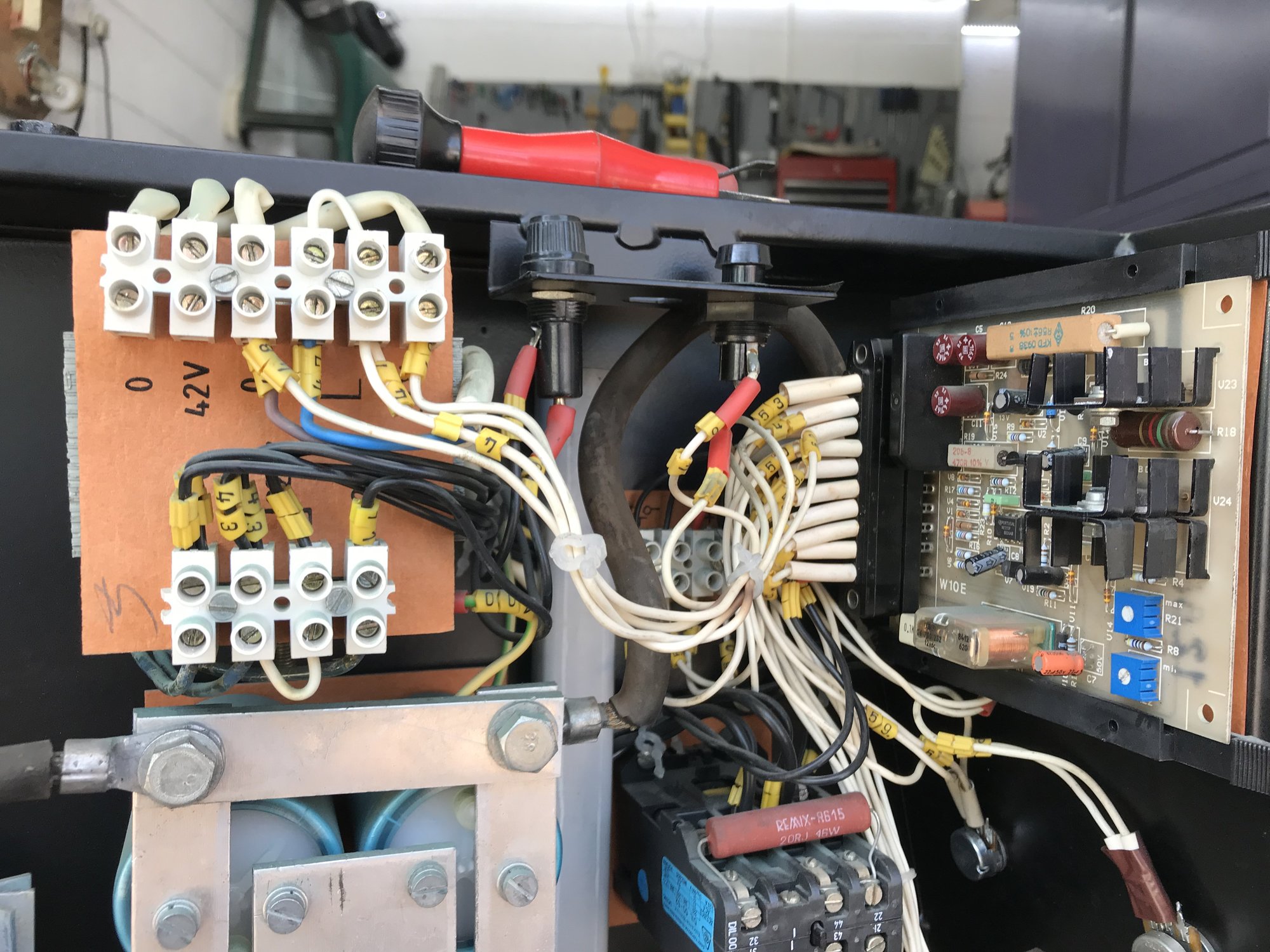

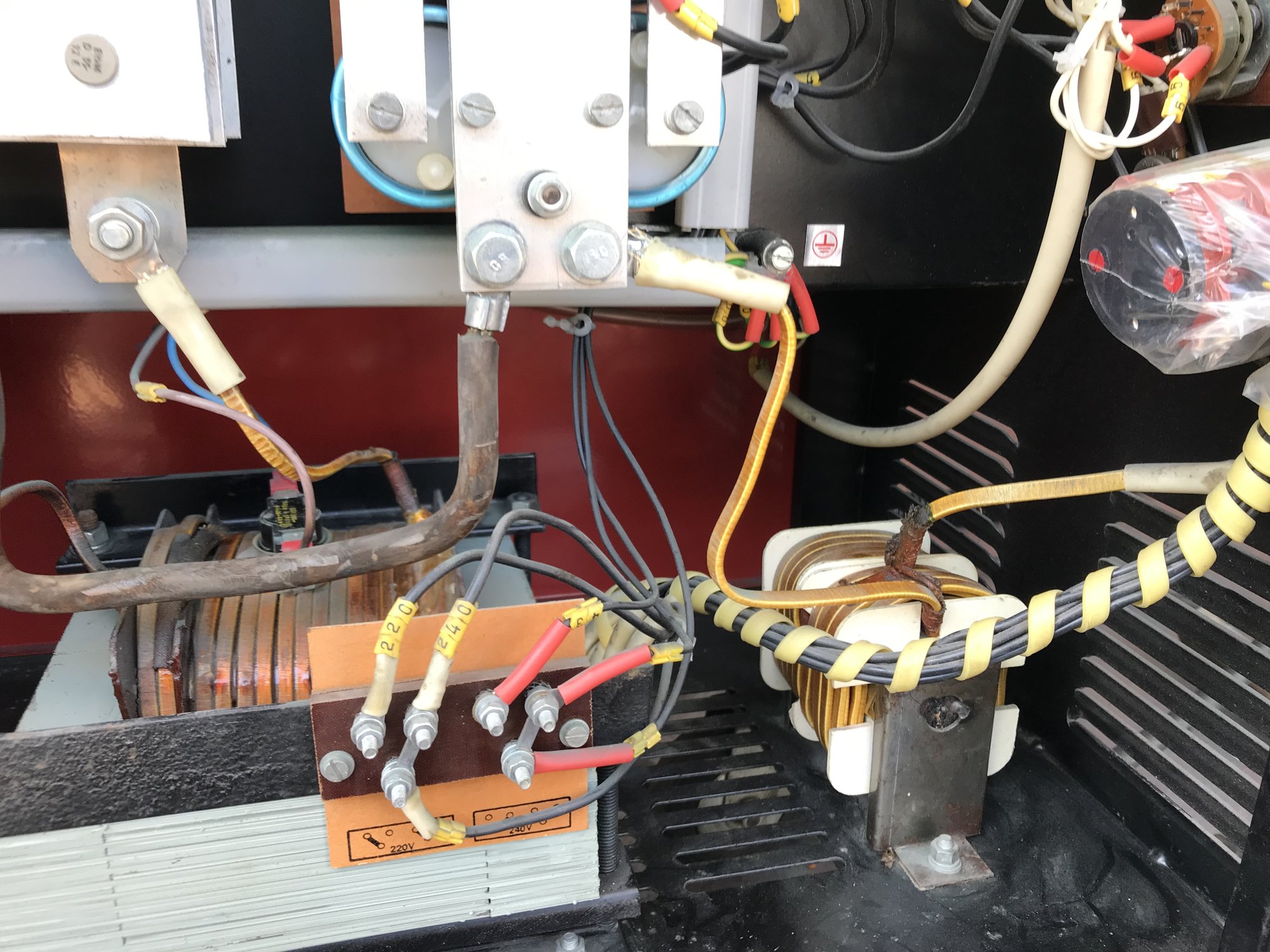

I thought it might be the earth, so I tried another lead but the same. I opened up the cabinet to look for loose/dirty joints, went all through them making sure they were tight, the capacitors look ok to me so I have run out of ideas.

Any thoughts or suggestions gratefully received.

I've had this machine for years, bought it second hand and not used it in a while.

Everything seemed fine, got gas and wire feed, can hear the relay kicking in on trigger but I get a spark but no ARC.

I thought it might be the earth, so I tried another lead but the same. I opened up the cabinet to look for loose/dirty joints, went all through them making sure they were tight, the capacitors look ok to me so I have run out of ideas.

Any thoughts or suggestions gratefully received.