You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

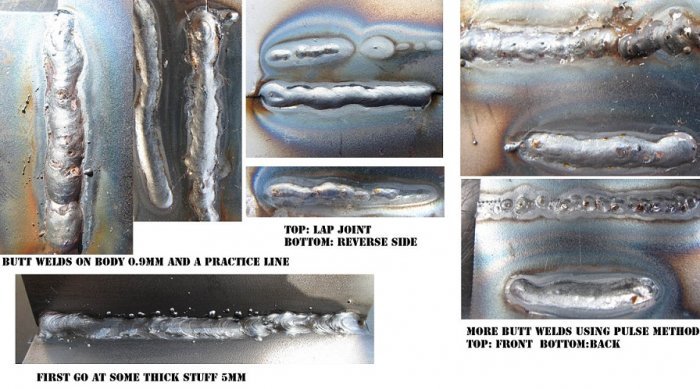

Some welds for you to have a chuckle at

- Thread starter SwissTony

- Start date

Chickenjohn

Morris Minor and Porsche 944 fan

- Messages

- 1,284

- Location

- East Kent

Those are really, really, good welds! As good as I can do. The only area that could be better is possibly your aim as some of the runs are not as straight as they could be but that will come with practise.

Did you use Argon/ CO2 mix?? I can weld neater at college with Argon/CO2 than I can at home with the Clark and CO2 only. Your weld beads look like mix rather than pure CO2.

Did you use Argon/ CO2 mix?? I can weld neater at college with Argon/CO2 than I can at home with the Clark and CO2 only. Your weld beads look like mix rather than pure CO2.

2nd pic on the left, that little wiggly line is just me playing around with settings rather than a proper weld, same on the 2 bottom welds on the right hand pics.

Had the settings wrong on the top right pic, top weld, that's why it looks better after about 1cm from the right.

Gas was Volkzone BOC argoshield light offer.

Had the settings wrong on the top right pic, top weld, that's why it looks better after about 1cm from the right.

Gas was Volkzone BOC argoshield light offer.

Chickenjohn

Morris Minor and Porsche 944 fan

- Messages

- 1,284

- Location

- East Kent

That is really good welding gas. What mig welder do you have?

Edit, just read that you have a Clark 160 on the other thread. That is a simmilar welder to mine. I did wonder if the reason for me getting much neater welds at college was due to the big expensive pro mig sets they have there or just the difference between CO2 and Argon/C02 mix. I think next cylinder I get for home , I might try a mix.

Sorry for hijacking your thread! As you've been helping me with my internet woes, I'll send you more steel just for postage next time.

Keep up the good practise, I would say good enough to start some small repairs on your car!

Edit, just read that you have a Clark 160 on the other thread. That is a simmilar welder to mine. I did wonder if the reason for me getting much neater welds at college was due to the big expensive pro mig sets they have there or just the difference between CO2 and Argon/C02 mix. I think next cylinder I get for home , I might try a mix.

Sorry for hijacking your thread! As you've been helping me with my internet woes, I'll send you more steel just for postage next time.

Keep up the good practise, I would say good enough to start some small repairs on your car!

Clarke 160tm

Had my first welding related injury today.

A neighbor came round as I had just finished running a line. After a quick chat I went back to what I was doing. I grabbed a piece of metal that I had just been welding on and burnt a nice slice through the gloves into my left index finger.

Finger will be fine, but now I need new gloves

Will teach me to pay attention.

Just re-read my original post.

Forgot to thank you for sorting me out that metal John.

Thanks again for sorting that out for me.

Had my first welding related injury today.

A neighbor came round as I had just finished running a line. After a quick chat I went back to what I was doing. I grabbed a piece of metal that I had just been welding on and burnt a nice slice through the gloves into my left index finger.

Finger will be fine, but now I need new gloves

Will teach me to pay attention.

Just re-read my original post.

Forgot to thank you for sorting me out that metal John.

Thanks again for sorting that out for me.

the snooper

getting older by the day

- Messages

- 21,063

- Location

- Hull UK

Clarke 160tm

Had my first welding related injury today.

A neighbor came round as I had just finished running a line. After a quick chat I went back to what I was doing. I grabbed a piece of metal that I had just been welding

ouch i did that years ago i had made an exhaust manifold with water cooling for a boat engine someone was speaking to me and i just grabbed it to turn it over no gloves either i said oh dear that seems a little warm or words to that effect. i had no finger prints for ages and my skin felt silky smooth.

never did it again cant think why

It started ok but the angle of the torch must have changed as the weld is wider on the bottom piece than it is on the upright piece.

I gave it a good slap with a club hammer, there was no movement and it sounded very solid.

I welded both sides of the upright piece, the other side which wasn't pictured, was more consistent angle wise but didn't look so good as I was working out wire speeds.

I gave it a good slap with a club hammer, there was no movement and it sounded very solid.

I welded both sides of the upright piece, the other side which wasn't pictured, was more consistent angle wise but didn't look so good as I was working out wire speeds.

BChild

SIP - enough with the mods!!!!

- Messages

- 1,023

It started ok but the angle of the torch must have changed as the weld is wider on the bottom piece than it is on the upright piece.

I gave it a good slap with a club hammer, there was no movement and it sounded very solid.

I welded both sides of the upright piece, the other side which wasn't pictured, was more consistent angle wise but didn't look so good as I was working out wire speeds.

I'm still working out my own technique for fillet? welding - at the moment it involves increasing power and wire speed by a healthy margin and then getting the torch shroud right up against the corner

BChild

SIP - enough with the mods!!!!

- Messages

- 1,023

Going by something I read somewhere, having the contact tip slightly proud of the shroud can help on that sort of weld. Won't be trying it myself as I can't afford to be buying more shrouds and tips on top of the new gloves I need.

I have an old one that I didn't throw away for that very reason

I'll let you know when I try it - if it makes it easier or not

Chickenjohn

Morris Minor and Porsche 944 fan

- Messages

- 1,284

- Location

- East Kent

I think getting a fillet weld just right is really a question of aim. Get plenty of light on the work piece and get your head so you can see the weld pool really well. Then with practice your aim will get better and the fillet weld will be right in the corner.

My Mig tip is slightly proud of the shroud but I think that is not the best for ensuring good shielding gas coverage.

One thing is certain- those welds are nothing to chuckle at! On a car they would all easily pass the MOT. good work!

My Mig tip is slightly proud of the shroud but I think that is not the best for ensuring good shielding gas coverage.

One thing is certain- those welds are nothing to chuckle at! On a car they would all easily pass the MOT. good work!

My Mig tip is slightly proud of the shroud but I think that is not the best for ensuring good shielding gas coverage.

I would have thought that working into a corner the gas coverage might be better, as the gas has only one main way to escape, straight down the line of the weld using the push method. On butt joints (and lap on thin stuff) the gas can escape quite easily as there isn't anything to confine it.

My tired painkiller riddled brain produced the above, so if its totally wrong, sorry

Chickenjohn

Morris Minor and Porsche 944 fan

- Messages

- 1,284

- Location

- East Kent

Yes, that is what i mean, on flat joins as opposed to corner fillets having the tip proud of the nozzle won't help gas coverage.

I pulled it rather than pushed it, which I now believe gives less penetration, which is no good  At the time I thought pull gave more penetration but less gas coverage.

At the time I thought pull gave more penetration but less gas coverage.

Fortunately this was only a practice piece and will only be used as a rest to hold light stuff off the ground.

If the weather is good this week, I will get out and try again.

When welding on the thick stuff, I couldn't see the weld pool, just a large greenish arc. Do I just need to up the shade on my mask to be able to see it?

At the time I thought pull gave more penetration but less gas coverage.

At the time I thought pull gave more penetration but less gas coverage.Fortunately this was only a practice piece and will only be used as a rest to hold light stuff off the ground.

If the weather is good this week, I will get out and try again.

When welding on the thick stuff, I couldn't see the weld pool, just a large greenish arc. Do I just need to up the shade on my mask to be able to see it?