You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some advice for a novice

- Thread starter woj

- Start date

Well, now I convinced myself that I can do it next time I'll need to do some welding work on my car parts. All I have learnt will have to wait until then, and also then I will be thinking about getting my own equipment. This is more difficult than the welding itself. the choice is basically between a good used one or a new chinese but decent one (considering the amount of welding I can forsee, the cheap-product-factor should not be an issue). I like the machine that I have rented (Rehm Tiger DC) for what it can do weld-wise, but I do not like its one-knob control system. In any case even a used one is in the range of 1000 Euros, this is twice as much as I would consider spending.

Another things is of course learning the AC welding on aluminium, but this somehow does not yet excite me so much, I still have so much to learn about DC welding.

Another things is of course learning the AC welding on aluminium, but this somehow does not yet excite me so much, I still have so much to learn about DC welding.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

Have a search for MIGTIG Italia they have ACDC sets going on ebay for little money. I've a Plasma by them, works a treat.

No wonder really, they look remarkably like R-techs

No wonder really, they look remarkably like R-techs

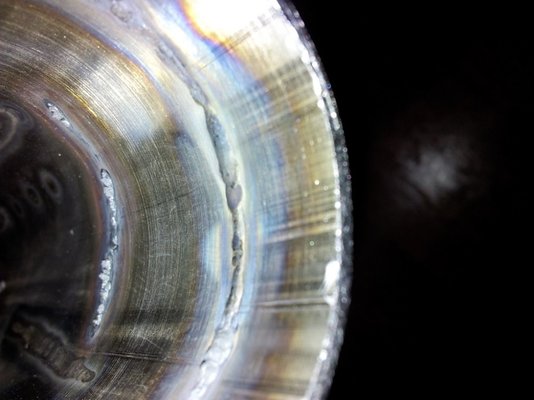

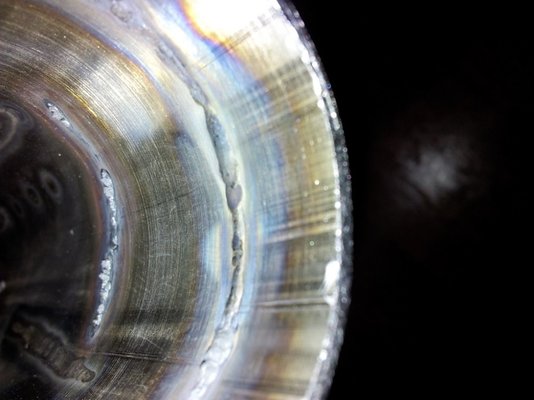

So my final weld turned out to be two. I made one with 45/20 amp split at 100Hz, it came out nice on the outside (first pic) on one half (the other half I somehow could not tune myself in), then I cut the pipe to see the inside (second pic) - not so good, penetration lacking in some places and I also forgot to turn on the back purge for one of the sections. But since I just had the pipe cut, I welded it again now at 50/20. This came out way better (third pic, the weld to the right), although it seems a bit more erratic on the pic, in reality it is much more uniform than the first one. Also I can see from the distance that the inside came out much better, but I am too lazy to cut the pipe again to check, perhaps on Friday.

So the inside of my last weld, better than the previous one, but still missing it in places. I guess I could have welded it with more juice still.

Anyhow, I got rid of the welder, one thing that I did not try, but wanted and forgot, is to see how the lift-arc starting works. Just to get an overview.

Anyhow, I got rid of the welder, one thing that I did not try, but wanted and forgot, is to see how the lift-arc starting works. Just to get an overview.

So I have one post-fact (as in I do not have access to the welder anymore) question. A while back I read here on this forum somwhere that the visual of the weld puddle gives a hint of whether the weld is penetrating through. I cannot find the post on that. Any insights on this? Instruction picture or video?