davidjohnperry

a different breed

- Messages

- 2,493

- Location

- yate/bristol

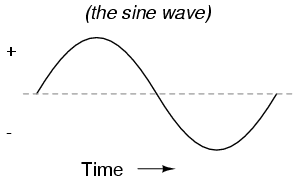

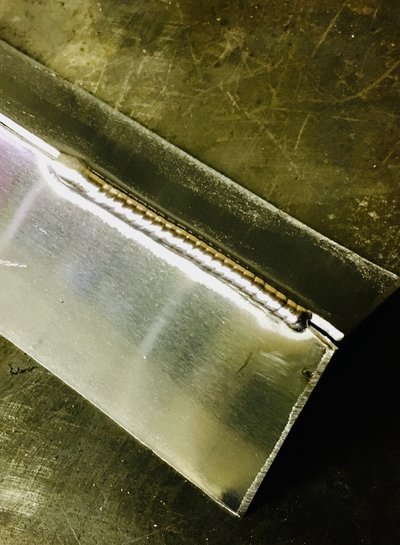

Got the sincosald fired up so nice having various Freq settings got to put the first 30 mins on her the torch is big but it's just a matter of getting used to it but I'm sofar happy with it there is a one thing that is a pain but it's not the end of all ends I might do a proper review on the machine when I get time

Here is a few pics of my first welds on the machine

At between 135 amps and 120 amps

120 Freq

110 freq

I should of let the weld cool between passes or dropped the amps but I'm just getting a feeling for the machine just for the moment

Here is a few pics of my first welds on the machine

At between 135 amps and 120 amps

120 Freq

110 freq

I should of let the weld cool between passes or dropped the amps but I'm just getting a feeling for the machine just for the moment