You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

small french hatchback

- Thread starter davenport

- Start date

hello hello my little octane lovin amigos!!

been a while and i could apologise, it really wouldnt be sincere though...

so i guess your all due an update.. so heres what i`ve been up to!

on the std 106 pedalbox the brake light activation switch is mounted off the actual pedal, seeings as i`m now running a bias pedalbox i needed to work out a new switch.. with the extra gubbins on the pedals room is tight, bloody tight! so a bit of head scratching and i ordered up 1 of these from goodridge:

and 1 of these:

the plan being installing it in the line running from front to back where the AP bias valve used to live between the seats.....

however!!

as you can see the switch is intended for a banjo fitting not a direct screw in... so.........

these were obtained:

(a massive shout to TRACY TOOLS, immense as ever!!)

and after a bit of fiddling:

this will now screw straight into the T and seal with a copper washer!!

next job....

oil pressure sensor!!!

the std sensor is just a simple on/off switch rather than a scaled item so i got on the phone to Pete @ KA sensors (again mega helpful guy, ive known him a while thru other projects so knew he`d be able to help)

i also got various fittings to go from the M16x1.5 in the block down to a -3 fitting for the sensor:

LOVE the test certificate! proper pro motorsport,, hahahaha

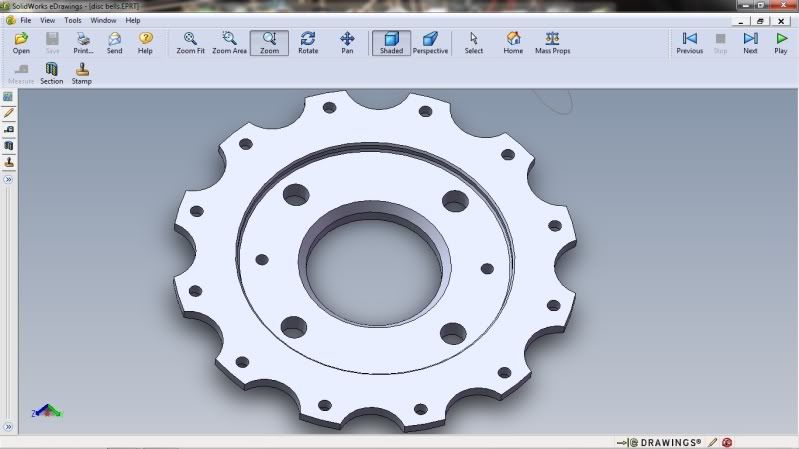

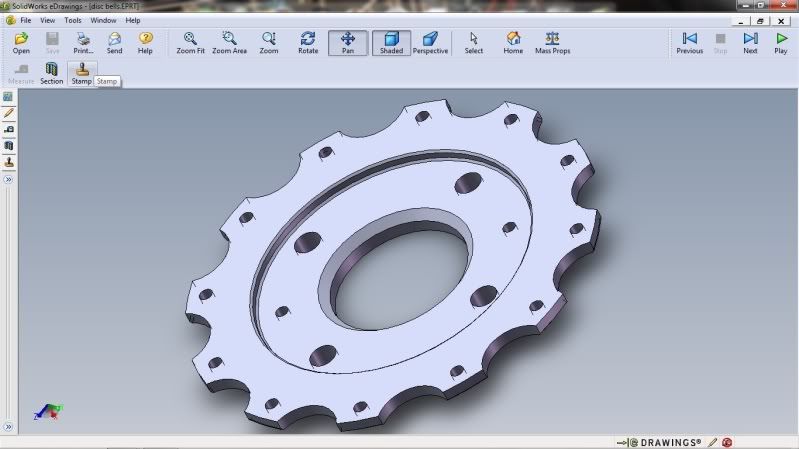

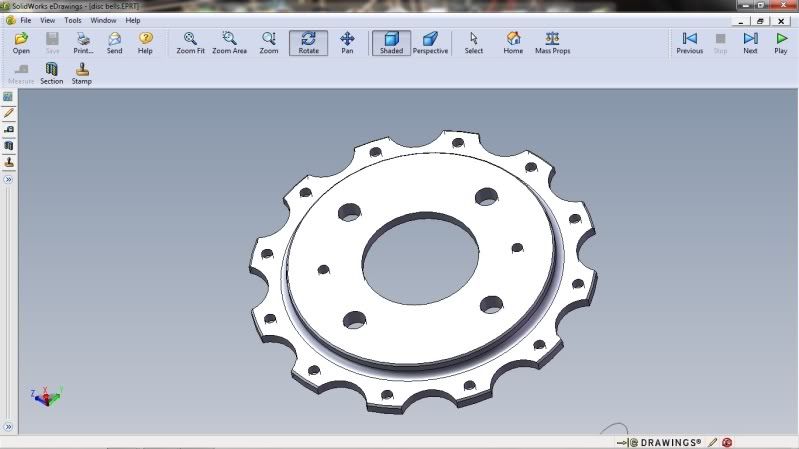

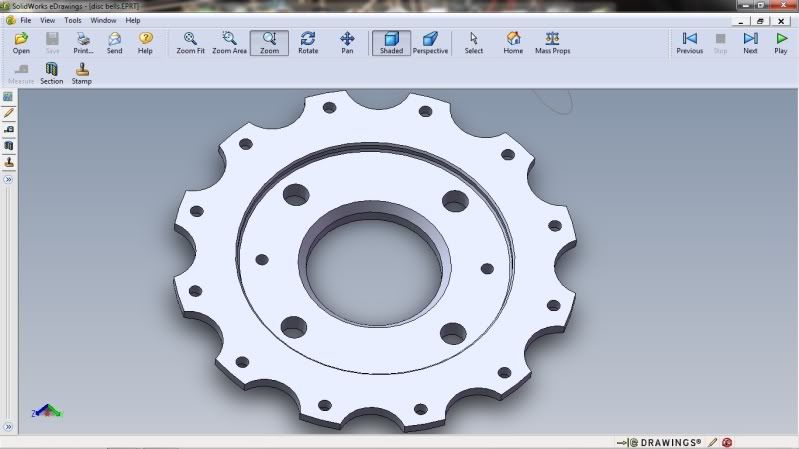

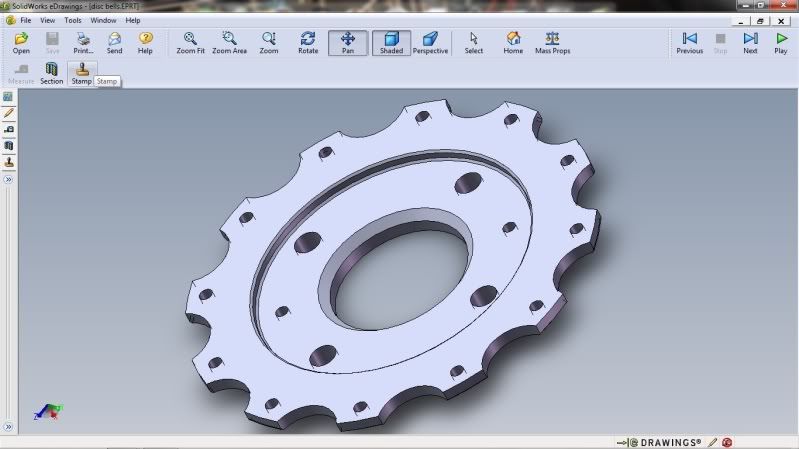

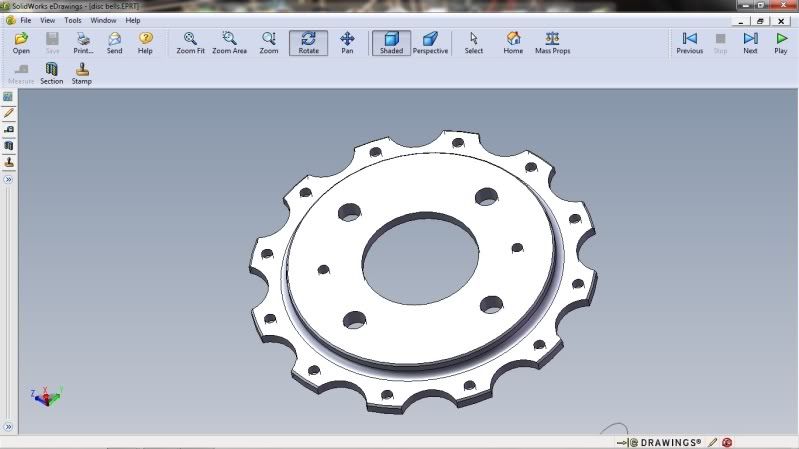

there was a small issue getting my disc bells machined and a new machinist had to be found..

i`d seen a blog about a guy up north (middlesboro) who had created some amazing parts for his motorbike:

http://homepage.ntlworld.com/shaun.wainford/Progress2.html

(honestly!! if you have 15 mins or so to kill this is an amazing read!!)

anyhow.. i emailed him, then phoned him, had a chat and liked his attitude! as a result he came up with these:

and a VERY attractive price, so they`re underway now which should see the braking side of things complete...

with regards to the wiring..... *SIGH*

still ongoing!! hahahahaha yeah yeah yeah i know, ive been saying that for a while!!

in fairness to Matt he has had some rather BIG projects on the go for VERY rich customers..

globe hopping with STARTA21`s fleet of cars including a lambo.. mosler... this!:

theres also been the PRAGA project involving the redesign or the drivetrain/electronics package of this:

originally a hayabusa based V8 which despite being ferociously quick (search youtube - "praga/slovakring" iirc) blew up after a few hours, not ideal for 24hour events!! so its been swapped to a renault/nissan V6

a LOT of trick bits and scary amounts of money but all seems well:

http://www.youtube.com/watch?v=9cgmsogPPdg

fingers crossed in the next month or so there will be some more steps forward with mine...

Cheers

Stu

been a while and i could apologise, it really wouldnt be sincere though...

so i guess your all due an update.. so heres what i`ve been up to!

on the std 106 pedalbox the brake light activation switch is mounted off the actual pedal, seeings as i`m now running a bias pedalbox i needed to work out a new switch.. with the extra gubbins on the pedals room is tight, bloody tight! so a bit of head scratching and i ordered up 1 of these from goodridge:

and 1 of these:

the plan being installing it in the line running from front to back where the AP bias valve used to live between the seats.....

however!!

as you can see the switch is intended for a banjo fitting not a direct screw in... so.........

these were obtained:

(a massive shout to TRACY TOOLS, immense as ever!!)

and after a bit of fiddling:

this will now screw straight into the T and seal with a copper washer!!

next job....

oil pressure sensor!!!

the std sensor is just a simple on/off switch rather than a scaled item so i got on the phone to Pete @ KA sensors (again mega helpful guy, ive known him a while thru other projects so knew he`d be able to help)

i also got various fittings to go from the M16x1.5 in the block down to a -3 fitting for the sensor:

LOVE the test certificate! proper pro motorsport,, hahahaha

there was a small issue getting my disc bells machined and a new machinist had to be found..

i`d seen a blog about a guy up north (middlesboro) who had created some amazing parts for his motorbike:

http://homepage.ntlworld.com/shaun.wainford/Progress2.html

(honestly!! if you have 15 mins or so to kill this is an amazing read!!)

anyhow.. i emailed him, then phoned him, had a chat and liked his attitude! as a result he came up with these:

and a VERY attractive price, so they`re underway now which should see the braking side of things complete...

with regards to the wiring..... *SIGH*

still ongoing!! hahahahaha yeah yeah yeah i know, ive been saying that for a while!!

in fairness to Matt he has had some rather BIG projects on the go for VERY rich customers..

globe hopping with STARTA21`s fleet of cars including a lambo.. mosler... this!:

theres also been the PRAGA project involving the redesign or the drivetrain/electronics package of this:

originally a hayabusa based V8 which despite being ferociously quick (search youtube - "praga/slovakring" iirc) blew up after a few hours, not ideal for 24hour events!! so its been swapped to a renault/nissan V6

a LOT of trick bits and scary amounts of money but all seems well:

http://www.youtube.com/watch?v=9cgmsogPPdg

fingers crossed in the next month or so there will be some more steps forward with mine...

Cheers

Stu

Angusdog

Well-meaning amateur

- Messages

- 726

- Location

- Wellington, NZ

i`d seen a blog about a guy up north (middlesboro) who had created some amazing parts for his motorbike:

http://homepage.ntlworld.com/shaun.wainford/Progress2.html

(honestly!! if you have 15 mins or so to kill this is an amazing read!!)

^^ Wow! That is an interesting read. Thanks for the link.

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

^^ Wow! That is an interesting read. Thanks for the link.

^^^^^^^^^^^^ WHS ^^^^^^^^^^^

One talented bloke, sounds like he has had a rough time though.

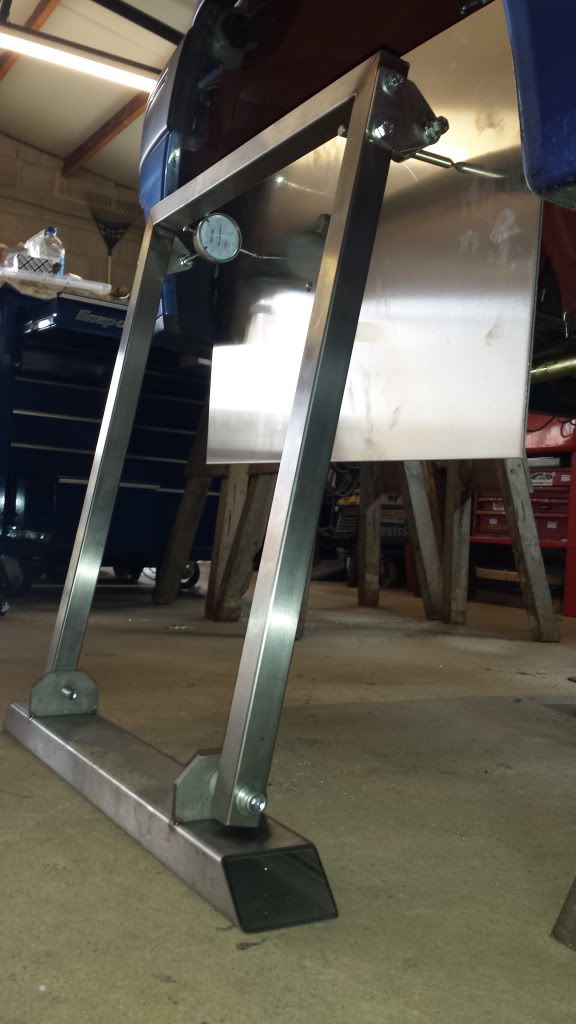

got a few pics sent from Shaun today...

billet bells step by step:

a massive thanks to Shaun for taking the pics during there machining (theres also a vid) finished items and mounts will be off to PeterboroughPlating for anodising and i can get things mounted up... (shaun also mentioned to ask for the bells to be in the ao-tank for the minimum time possible or i`ll lose the machining marks (something that happened to him on his bike parts)

billet bells step by step:

a massive thanks to Shaun for taking the pics during there machining (theres also a vid) finished items and mounts will be off to PeterboroughPlating for anodising and i can get things mounted up... (shaun also mentioned to ask for the bells to be in the ao-tank for the minimum time possible or i`ll lose the machining marks (something that happened to him on his bike parts)

tattyjeans

New Member

- Messages

- 2

I have just purchased a Saxo for her indoors, and have tried to explain what "gusset rot" implies.... I am looking forward to showing her the pictures and expect some panic....

Rather than copy the original panel slavishly, it occurred to me to make it into a jacking point proper. A little bit of square section inside, to make it rock solid.....one little drain hole with a radius pressed in. I'll post pictures when I do the other side!

Rather than copy the original panel slavishly, it occurred to me to make it into a jacking point proper. A little bit of square section inside, to make it rock solid.....one little drain hole with a radius pressed in. I'll post pictures when I do the other side!

octo0072000

Member

- Messages

- 5,994

- Location

- south yorks

brake light switch

with the brake light switch a standard old type mini uses a switch that that screws into a brass tee piece no machining needed

http://www.ebay.co.uk/itm/CLASSIC-M...arts_Vehicles_CarParts_SM&hash=item416d2cacee

with the brake light switch a standard old type mini uses a switch that that screws into a brass tee piece no machining needed

http://www.ebay.co.uk/itm/CLASSIC-M...arts_Vehicles_CarParts_SM&hash=item416d2cacee

alright folks...

been a while aint it!!???

apologies for not being on here much.. this little fella has been taking up a LOT of time:

so, where am I on the car???

well.. the disc bells got finished:

and mated up with the AP discs:

clearance is TIGHT!!!

but all good.... unfortunately, the clearance between the wishbone and the inner disc face was also as tight!!:

there was only 1 sensible solution:

the std 106 legs were sold, and I treated myself to a set of fabricated struts from Colin down @ SatchellEngineering

these differ from the std legs in that the hub (a modified 307 unit) is separate, the ackerman has been altered slightly and thanks to the hub layout the wishbone balljoint is much lower not only giving better brake clearance but also helping the roll centre and bumpsteer correction.....

as for the wiring....

ahhhhhhh the wiring.... its a LONG story but the basics are, I found out a few things I was told regarding progress turned out to be bare faced lies, so I lost my temper and had the car collected and brought home, a new manufacturer has been commissioned to do the job and is currently working on it...

that's about it tbh.....

cheers

Stu

been a while aint it!!???

apologies for not being on here much.. this little fella has been taking up a LOT of time:

so, where am I on the car???

well.. the disc bells got finished:

and mated up with the AP discs:

clearance is TIGHT!!!

but all good.... unfortunately, the clearance between the wishbone and the inner disc face was also as tight!!:

there was only 1 sensible solution:

the std 106 legs were sold, and I treated myself to a set of fabricated struts from Colin down @ SatchellEngineering

these differ from the std legs in that the hub (a modified 307 unit) is separate, the ackerman has been altered slightly and thanks to the hub layout the wishbone balljoint is much lower not only giving better brake clearance but also helping the roll centre and bumpsteer correction.....

as for the wiring....

ahhhhhhh the wiring.... its a LONG story but the basics are, I found out a few things I was told regarding progress turned out to be bare faced lies, so I lost my temper and had the car collected and brought home, a new manufacturer has been commissioned to do the job and is currently working on it...

that's about it tbh.....

cheers

Stu

Cris B

Every day welding is a school day

- Messages

- 512

- Location

- Sefton

ahhhhhhh the wiring.... its a LONG story but the basics are, I found out a few things I was told regarding progress turned out to be bare faced lies, so I lost my temper and had the car collected and brought home, a new manufacturer has been commissioned to do the job and is currently working on it...

Blimey, I think we could compare notes on this topic over a beer

Nonetheless onwards and upwards

BeeJay99

Forum Supporter

- Messages

- 185

Managed to get some 1/2 unf inserts (2 left hand, 2 right hand) and some tube so got busy making some steering arms... these might need a tweek in the tube bender to clear the rack.. will check that at the weekend...

Two questions...

1. How much tweak will the rods tolerate before they become vulnerable to steering loads causing them to bend further?

2. Did you consider putting any kind of hex (in the geometric and not the voodoo sense) on the rods to make gripping them while adjusting them easier? I have bored out a plain nut, slid it over the exposed part of one of the inserts and welded it there in the past to achieve this.

I have 2 unplated M20 nuts sat on my toolbox waiting to be bored out to 1" for adjustement...

as for how much bend is too much.. as it happens thanks to the reduced length of the arm on the strut I dont need to bend them at all.. but even with the old setup it was only around the 5° mark.. enough to lower their strength certainly but not enough to cause any issues in terms of flex or creating a dangerous weak spot...

as for how much bend is too much.. as it happens thanks to the reduced length of the arm on the strut I dont need to bend them at all.. but even with the old setup it was only around the 5° mark.. enough to lower their strength certainly but not enough to cause any issues in terms of flex or creating a dangerous weak spot...

them struts looks awesome!

Thank you, I'm very pleased with them.. but all credit must go to Dave + Colin Satchell

madkayaker

Pro sparkey Pro Welder

- Messages

- 13,678

Another example of the annoyance of people using photo bucket most of the photos have gone!

- Messages

- 23,939

- Location

- Birmingham

Another example of the annoyance of people using photo bucket most of the photos have gone!

Easy solution, just add to ignore list