Thrashsmith

Member

- Messages

- 709

I bought a powered ring/section roller the other day, not a commercially made set, they're a very well made home made set. I think I'm the 3rd owner, including whoever made them.

They've only got flat rollers on currently but with a bit of jiggery pokery I think some dies could be slipped on that will prevent box section/circular hollow from deforming.

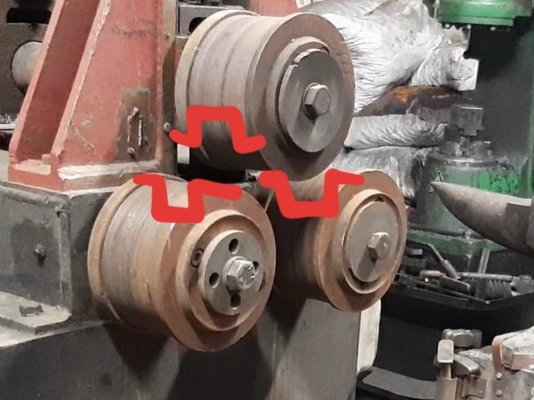

Question is: if I was rolling 40mm SHS for example, how much of the vertical face needs to be covered to prevent it pooching out? I've attached a crappy sketch to help illustrate what I mean.

I'm not looking roll 40mm SHS specifically, it's more of a generalized question. How much of the profile needs covering to prevent drastic distortion? One third? Half?

Cheers

They've only got flat rollers on currently but with a bit of jiggery pokery I think some dies could be slipped on that will prevent box section/circular hollow from deforming.

Question is: if I was rolling 40mm SHS for example, how much of the vertical face needs to be covered to prevent it pooching out? I've attached a crappy sketch to help illustrate what I mean.

I'm not looking roll 40mm SHS specifically, it's more of a generalized question. How much of the profile needs covering to prevent drastic distortion? One third? Half?

Cheers

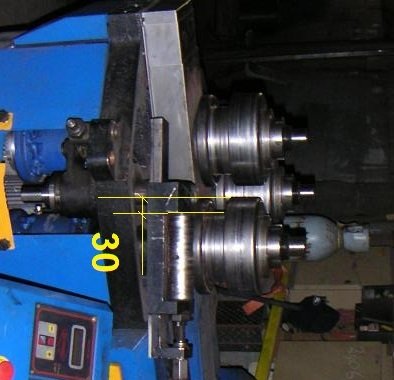

Where does the 30mm dimension you mention relate to?

Where does the 30mm dimension you mention relate to?