Burdekin

Chief Bodger

- Messages

- 6,657

- Location

- Aberdeen

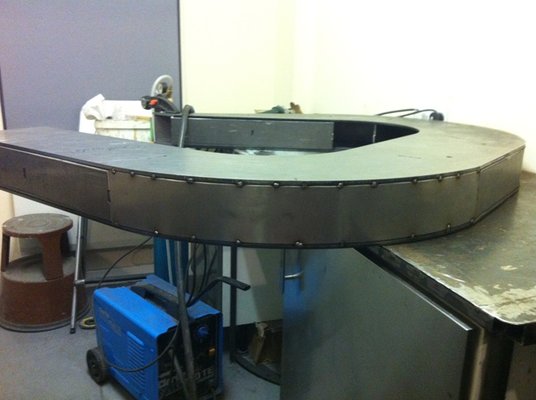

My Scottish Wheel build with a touch of English, American and Aussie thrown in; laser cut in England, wheels and adjuster from the US and welded and assembled by an Aussie living in Scotland. It's a 30" and the plan is it will get well used when she is finished.

I'm going to make this photo heavy and try not to rabbit on too much with words. I started last night and a little tonight with getting it all to fit together which involved filing the slots and tabs which locate it all together.

I'll just post as I go along but hopefully it will be a short build...

I'm going to make this photo heavy and try not to rabbit on too much with words. I started last night and a little tonight with getting it all to fit together which involved filing the slots and tabs which locate it all together.

I'll just post as I go along but hopefully it will be a short build...

-

IMG_1303.jpg49.7 KB · Views: 2,026

IMG_1303.jpg49.7 KB · Views: 2,026 -

IMG_1304.jpg82.4 KB · Views: 2,010

IMG_1304.jpg82.4 KB · Views: 2,010 -

IMG_1305.jpg38.7 KB · Views: 1,996

IMG_1305.jpg38.7 KB · Views: 1,996 -

IMG_1306.jpg33.4 KB · Views: 1,991

IMG_1306.jpg33.4 KB · Views: 1,991 -

IMG_1309.jpg28.8 KB · Views: 1,995

IMG_1309.jpg28.8 KB · Views: 1,995 -

IMG_1312.jpg74.1 KB · Views: 1,992

IMG_1312.jpg74.1 KB · Views: 1,992 -

IMG_1323.jpg109.6 KB · Views: 1,998

IMG_1323.jpg109.6 KB · Views: 1,998 -

IMG_1327.jpg41.9 KB · Views: 1,990

IMG_1327.jpg41.9 KB · Views: 1,990 -

IMG_1329.jpg49.5 KB · Views: 2,007

IMG_1329.jpg49.5 KB · Views: 2,007 -

IMG_1330.jpg55.7 KB · Views: 2,011

IMG_1330.jpg55.7 KB · Views: 2,011

...

...