Someone was asking about having a lathe and milling machine recently, thought I'd bore everyone with what I used mine for today (the mill).

I repaired a mower bracket that I'd previously repaired (previously I just vee'd out the cracked area and re-welded, so the result was inevitable really).

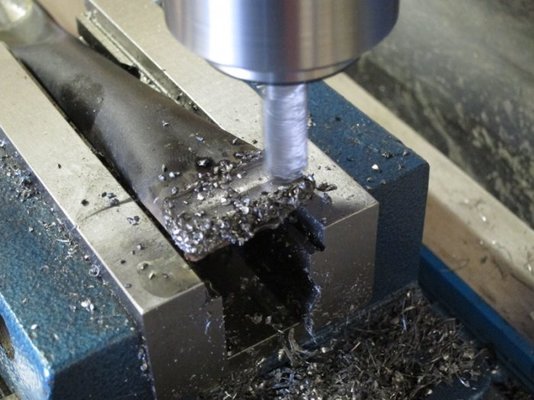

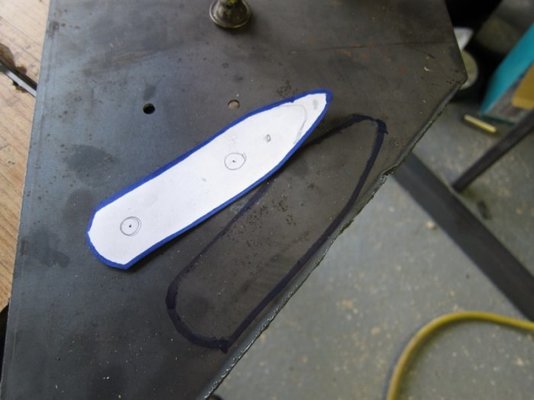

Made a new flange(?) from 3mm plate, cut it freehand on the plasma. Milled the end flat of the remaining piece of the bracket, then tidied the new piece on the bench grinder, drilled the holes and then got into welding the two back together. I thought it'd be tricky with the relative thickness of the new piece vs the tube walls, needn't have worried. I did use the pedal on the TIG.

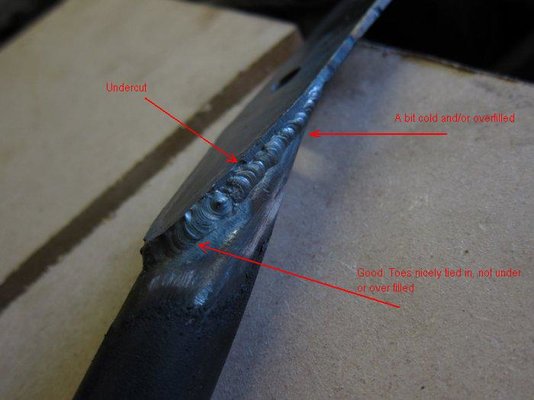

Would love to have comments on the welding, feel like it's coming on but think there are still bits I can do better. In particular, the coordination, I spent more time positioning the bracket to my comfort, not going to be possible on larger items.

I repaired a mower bracket that I'd previously repaired (previously I just vee'd out the cracked area and re-welded, so the result was inevitable really).

Made a new flange(?) from 3mm plate, cut it freehand on the plasma. Milled the end flat of the remaining piece of the bracket, then tidied the new piece on the bench grinder, drilled the holes and then got into welding the two back together. I thought it'd be tricky with the relative thickness of the new piece vs the tube walls, needn't have worried. I did use the pedal on the TIG.

Would love to have comments on the welding, feel like it's coming on but think there are still bits I can do better. In particular, the coordination, I spent more time positioning the bracket to my comfort, not going to be possible on larger items.

bet it cost a fortune in time but you can't put a price on the satisfaction value

bet it cost a fortune in time but you can't put a price on the satisfaction value