Pollys13

Member

- Messages

- 377

- Location

- Wiltshire UK

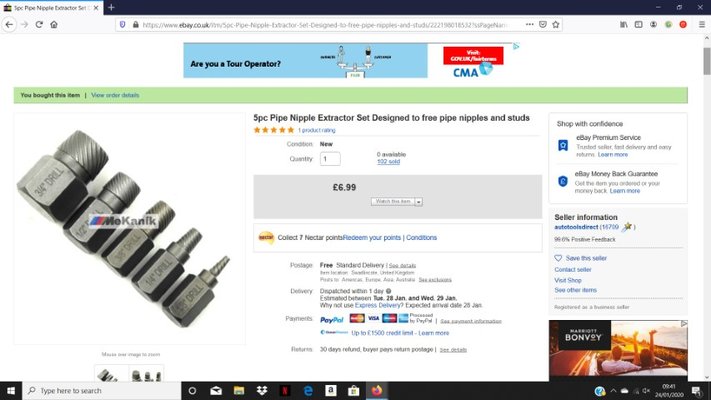

After receiving advice on the forum, thanks  I bought a set of nipple extractors. Using a butane torch to free up the Loctite stuff. I'm wondering how the paint might react with the heat? If powder coated I have a feeling, it will pretty much stay put. If another finish might flake and bits fall into the 120 grit, which I think should be avoided if poss.

I bought a set of nipple extractors. Using a butane torch to free up the Loctite stuff. I'm wondering how the paint might react with the heat? If powder coated I have a feeling, it will pretty much stay put. If another finish might flake and bits fall into the 120 grit, which I think should be avoided if poss.

So should I fit the nipple extractor into the end of pipe, then heat up, would perhaps expand the extractor making a tighter fit but could also expand the end of the pipe making harder to get out? I'm thinking of a 10 second burst with the torch, which I've used to get other fittings off, is 10 seconds too long?

Please advise.

Cheers.

I bought a set of nipple extractors. Using a butane torch to free up the Loctite stuff. I'm wondering how the paint might react with the heat? If powder coated I have a feeling, it will pretty much stay put. If another finish might flake and bits fall into the 120 grit, which I think should be avoided if poss.

I bought a set of nipple extractors. Using a butane torch to free up the Loctite stuff. I'm wondering how the paint might react with the heat? If powder coated I have a feeling, it will pretty much stay put. If another finish might flake and bits fall into the 120 grit, which I think should be avoided if poss.So should I fit the nipple extractor into the end of pipe, then heat up, would perhaps expand the extractor making a tighter fit but could also expand the end of the pipe making harder to get out? I'm thinking of a 10 second burst with the torch, which I've used to get other fittings off, is 10 seconds too long?

Please advise.

Cheers.