Gragson

Member

- Messages

- 2,590

- Location

- Bucks

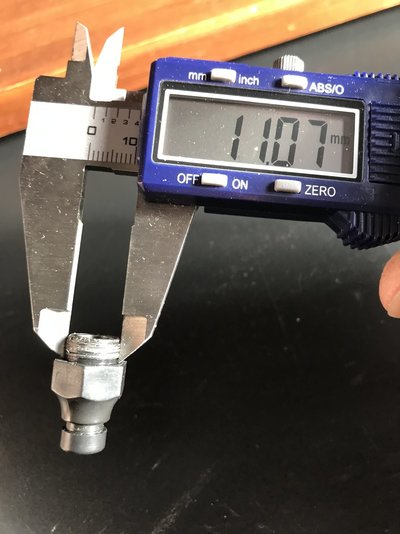

Stripped & rebuilt a carb on a poorly running cb250, it has a choke valve/plunger that is secured by this plastic nut that screws into the aluminum carb body, its strpped and will not nip up. The part appears to be NLA from Honda and the thieves known as CMSNL want over £60 delivered as it comes with a spring and the wee 50p valve. Tried a bit of PTFE but its still not nipping up enough to my liking.

I was thinking of smearing a tiny bit of JB weld on the thread and turning back in then out to let it dry hoping it would make a better thread (not a great bodge..), there is only about 3mm of thread to start with.

Any better ideas folks?

I was thinking of smearing a tiny bit of JB weld on the thread and turning back in then out to let it dry hoping it would make a better thread (not a great bodge..), there is only about 3mm of thread to start with.

Any better ideas folks?