You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

radio controlled Matchbox lorry.

- Thread starter optima21

- Start date

well since you want more, here's an update

so this is how it was when I was running it the other day......I think the wiring may need a bit of tidying up

and drilling and taping the original rivets 10ba to screw the body to the chassis. this went a bit wrong though as the trace of cutting oil on my hands removed some of the printed detailing on the body, so now I'm waiting for another truck to use the body off. a hole was also drilled and filed in the floor for the motor to go though

then I needed the equivalent of 10ba penny washers but 5mm o/d for mounting the body to the chassis so its a case of turning them from 0.6mm brass (this before turning the washer .

then the internals of the plastic moulding for the parts of the boiler, engine and cab interior needed to be hollowed out to fit over the steering servo. easiest way to do this was use a metal plate to clamp and screw the moulding to.

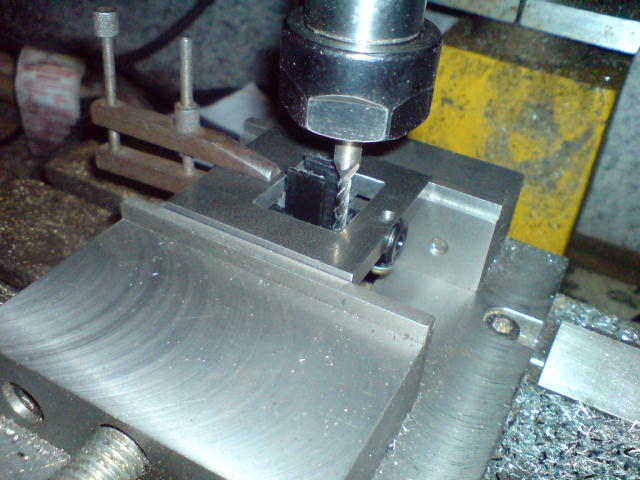

and being milled out with a long series 1/8 dia end mill.

and the modified moulding over the servo

the wires will be hidden when I decide where to route them to the back. and it will be covered by the body

ahh you dont have to worry about tyre wear on solid plastic tyres

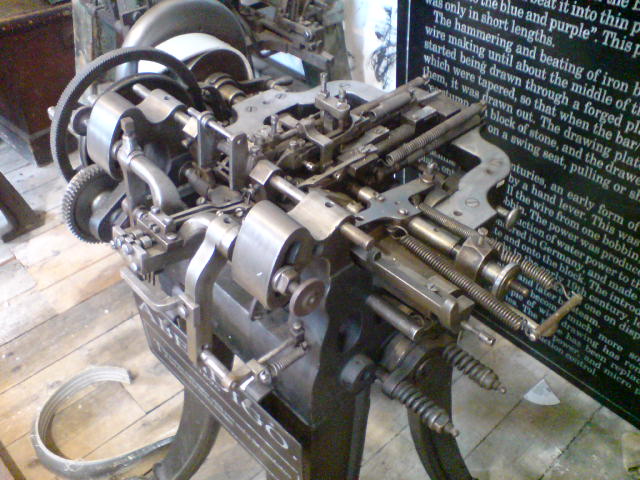

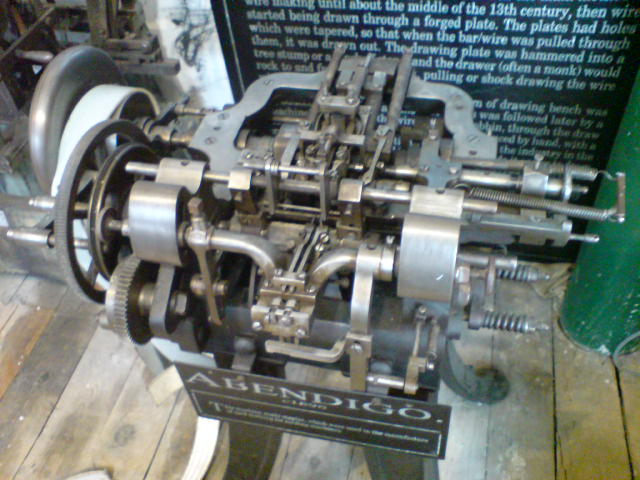

but some new links were made which were more accurate and are basically staples.... so slightly off topic is a machine that is over 120 years old and was used to make staples from coils of wire and punch them though leather or rubber belting that are used in carding machines for use in textile manufacture

so this is how it was when I was running it the other day......I think the wiring may need a bit of tidying up

and drilling and taping the original rivets 10ba to screw the body to the chassis. this went a bit wrong though as the trace of cutting oil on my hands removed some of the printed detailing on the body, so now I'm waiting for another truck to use the body off. a hole was also drilled and filed in the floor for the motor to go though

then I needed the equivalent of 10ba penny washers but 5mm o/d for mounting the body to the chassis so its a case of turning them from 0.6mm brass (this before turning the washer .

then the internals of the plastic moulding for the parts of the boiler, engine and cab interior needed to be hollowed out to fit over the steering servo. easiest way to do this was use a metal plate to clamp and screw the moulding to.

and being milled out with a long series 1/8 dia end mill.

and the modified moulding over the servo

the wires will be hidden when I decide where to route them to the back. and it will be covered by the body

although think the toe in is excessive

ahh you dont have to worry about tyre wear on solid plastic tyres

but some new links were made which were more accurate and are basically staples.... so slightly off topic is a machine that is over 120 years old and was used to make staples from coils of wire and punch them though leather or rubber belting that are used in carding machines for use in textile manufacture

arther dailey

Member

- Messages

- 6,973

- Location

- England

similar to the metal links in the belts that drive old machinery from overhead pulleys I geuss ,love old machinery like that.

after looking at the last picture of the truck (shown above), I decided that the chimney looked awful with the curved sides, would look better with straight tapered sides and a polished brass top, so it would be rude not to make one. turning the round part of the chimney.

milling the rectangle at the bottom to mount it.

and shown with the top cap and the original chimney, I think mine will look better on the completed model

with the wire from the servo I decided to mill a section out of the cab floor as the back of the "boiler" had been cut out to fit the steering servo and the hole was big enough to fit the servo plug through.

and a hole for the servo lead was cut in the body floor

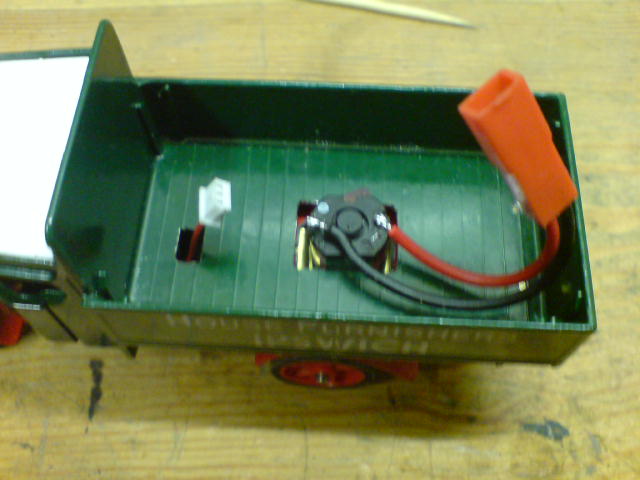

the receiver (above the motor and under the red connector) and speed controller (below right of the motor) were then plugged in

and then the battery was placed on top of that. it quite happily runs like that without being fixed in place.

and by the looks of it, if I used a smaller battery and smaller power connectors, I could have had enough space to have a foden coal waggon rather than a removal waggon like the one below.

I do prefer the graphics on the removal waggon and the cover is nice and easy to get off to get to the battery.

and here is how mine is looking now.

so the next post is likely to be 2 or 3 weeks away and thats to paint it. Im thinking of having it look very similar, with a black chassis but keep the red mudgards. and try and brighten up the cab interior so you can see some of the detail.

milling the rectangle at the bottom to mount it.

and shown with the top cap and the original chimney, I think mine will look better on the completed model

with the wire from the servo I decided to mill a section out of the cab floor as the back of the "boiler" had been cut out to fit the steering servo and the hole was big enough to fit the servo plug through.

and a hole for the servo lead was cut in the body floor

the receiver (above the motor and under the red connector) and speed controller (below right of the motor) were then plugged in

and then the battery was placed on top of that. it quite happily runs like that without being fixed in place.

and by the looks of it, if I used a smaller battery and smaller power connectors, I could have had enough space to have a foden coal waggon rather than a removal waggon like the one below.

I do prefer the graphics on the removal waggon and the cover is nice and easy to get off to get to the battery.

and here is how mine is looking now.

so the next post is likely to be 2 or 3 weeks away and thats to paint it. Im thinking of having it look very similar, with a black chassis but keep the red mudgards. and try and brighten up the cab interior so you can see some of the detail.

Dutch Welder

Member

- Messages

- 411

- Location

- Oss, The Netherlands

This sort of very small stuff would drive my totally bonkers, very impressive.

as it was so small I decided that it would be best to update my painting gear and so decided to get a new compressor and airbrush. for less than £100 I got a oil free piston compressor with receiver and filter/regulator and a 0.3mm airbrush. the compressor cut off at 4 bar and are almost silent in operation so could be used for a quick blow down with air if a normal full sized air compressor is too noisy.

I got this from Scale Model Shop

https://www.scalemodelshop.co.uk/product/as-186s-sms-092-compressor-airbrush-bundle-hose

and also got model paints, paint brushes, and masking tape etc from them too. and if you want to mask small items, I was using masking fluid and Tamiya masking tape. I was using 6mm wide straight tape and 2mm wide tape for curves (seems to be a bit like narrow insulation tape).

the chassis and steering/suspension parts were grit blasted using fine crushed glass and a pressure of 25 to 30 psi, and it works well on the smaller parts...it helps to hold them on the cocktail sticks

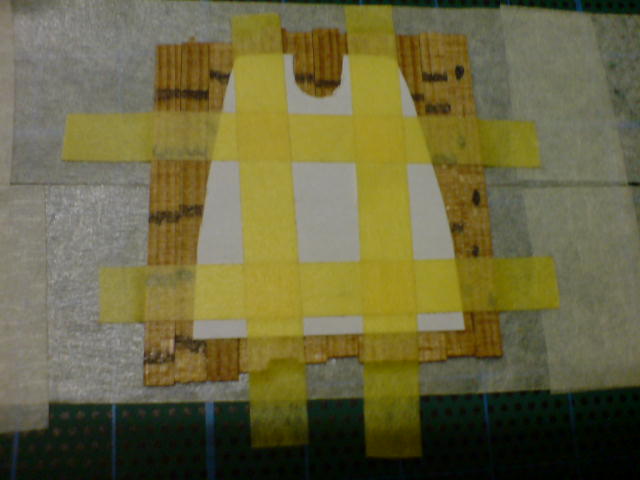

I decided that I wanted a wooden roof, cab back and floor, so used some 3mm wide planks cut from veneer. shown here with a template for the roof before I cut it to shape.

the planks were then clamped and glued into the cab

and a new flywheel would look better than the one that can with the truck. this is 8mm o/d

so this is the top half of the boiler, engine and cab interior, which is a shame that it can't really be seen and as standard it comes as black from matchbox. Im impressed with how well the paintwork came out and the airbrush and decent masking tape helped with this. As standard with the matchbox truck the steering wheel has a vertical column, but in reality they were always at an angle, which resulted in me making a tiny little bracket to achieve this.

and finally when the painting is done there is a kit of parts to assemble (there a few more bits than as it came from matchbox)

coming together now, shame I have to put the body on top

and the completed radio controlled matchbox truck

and here it is compared to a standard one and mine is on the right if you dont know. I have to say that mine looks better than the standard one, I just wish I could have kept the front suspension that was cast into the chassis, but it had to go as there wasn't enough metal there to leave it and have working steering.

and now that is finished, the boat at the start of the past should be with me next week, so this wasn't a bad refresher on radio control models and model painting.

I got this from Scale Model Shop

https://www.scalemodelshop.co.uk/product/as-186s-sms-092-compressor-airbrush-bundle-hose

and also got model paints, paint brushes, and masking tape etc from them too. and if you want to mask small items, I was using masking fluid and Tamiya masking tape. I was using 6mm wide straight tape and 2mm wide tape for curves (seems to be a bit like narrow insulation tape).

the chassis and steering/suspension parts were grit blasted using fine crushed glass and a pressure of 25 to 30 psi, and it works well on the smaller parts...it helps to hold them on the cocktail sticks

I decided that I wanted a wooden roof, cab back and floor, so used some 3mm wide planks cut from veneer. shown here with a template for the roof before I cut it to shape.

the planks were then clamped and glued into the cab

and a new flywheel would look better than the one that can with the truck. this is 8mm o/d

so this is the top half of the boiler, engine and cab interior, which is a shame that it can't really be seen and as standard it comes as black from matchbox. Im impressed with how well the paintwork came out and the airbrush and decent masking tape helped with this. As standard with the matchbox truck the steering wheel has a vertical column, but in reality they were always at an angle, which resulted in me making a tiny little bracket to achieve this.

and finally when the painting is done there is a kit of parts to assemble (there a few more bits than as it came from matchbox)

coming together now, shame I have to put the body on top

and the completed radio controlled matchbox truck

and here it is compared to a standard one and mine is on the right if you dont know. I have to say that mine looks better than the standard one, I just wish I could have kept the front suspension that was cast into the chassis, but it had to go as there wasn't enough metal there to leave it and have working steering.

and now that is finished, the boat at the start of the past should be with me next week, so this wasn't a bad refresher on radio control models and model painting.

, can’t wait that long. I can but don’t want to. This must be one of the most fun projects I’ve seen for a while

, can’t wait that long. I can but don’t want to. This must be one of the most fun projects I’ve seen for a while