Hi!

I've just registered to ask you for some advice. The tutorial on the main page has been very helpfull, however, I'm a bit unsure and some questions remain.

I hope you can understand everything, I'm trying my best. I'm from germany so my english is not the very best and my grammar might be a bit weird. Appologies for that!

I've been practicing a lot lately.

So basically, my question is, is this OK?

Steel is 1mm sheet. Welder is a Güde MIG190 (30-200A, 230V). 0.6mm wire and Argon gas with 18% CO². Current was set to level 2 (of 8), wire speed to 15 (digital range from 5 to 99). I set a tack every 2cm and then used the 'step back'/'pilgrim step' technique to form a continuous seam and keep distortion at bay (one spot after the other, as far apart as possible).

When ground back, there are no light leaks, the seam is solid and through. However, I'm in doubt of the back side of the seam, showing only punctual burn through. The spots however sit in the middle of the sheet.

As you can see, there are still some 'cold' welds. I've solved that problem with using a higher power setting for the last joining spot (when joining the seam sections). Or grinding the weld back and then set the last joining spots. Which worked.

So; does this look OK for a non-continuous butt weld? Can I attack a car with my current skills?

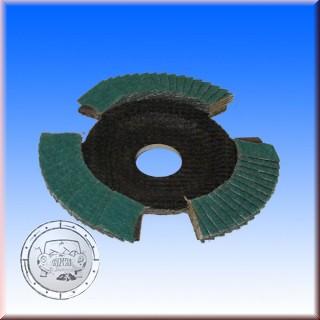

Next the plug-welds. Again 1mm sheet, power setting at 3, wire speed at 17. 5mm holes.

I'm quite happy with those. Do you agree? When pulled apart, the weld doesn't separate and rather rips a hole in the sheet.

When pulled apart, the weld doesn't separate and rather rips a hole in the sheet.

Thank you for taking the time & awnsering my questions!!

Best regards,

Jan

I've just registered to ask you for some advice. The tutorial on the main page has been very helpfull, however, I'm a bit unsure and some questions remain.

I hope you can understand everything, I'm trying my best. I'm from germany so my english is not the very best and my grammar might be a bit weird. Appologies for that!

I've been practicing a lot lately.

So basically, my question is, is this OK?

Steel is 1mm sheet. Welder is a Güde MIG190 (30-200A, 230V). 0.6mm wire and Argon gas with 18% CO². Current was set to level 2 (of 8), wire speed to 15 (digital range from 5 to 99). I set a tack every 2cm and then used the 'step back'/'pilgrim step' technique to form a continuous seam and keep distortion at bay (one spot after the other, as far apart as possible).

When ground back, there are no light leaks, the seam is solid and through. However, I'm in doubt of the back side of the seam, showing only punctual burn through. The spots however sit in the middle of the sheet.

As you can see, there are still some 'cold' welds. I've solved that problem with using a higher power setting for the last joining spot (when joining the seam sections). Or grinding the weld back and then set the last joining spots. Which worked.

So; does this look OK for a non-continuous butt weld? Can I attack a car with my current skills?

Next the plug-welds. Again 1mm sheet, power setting at 3, wire speed at 17. 5mm holes.

I'm quite happy with those. Do you agree?

When pulled apart, the weld doesn't separate and rather rips a hole in the sheet.

When pulled apart, the weld doesn't separate and rather rips a hole in the sheet.Thank you for taking the time & awnsering my questions!!

Best regards,

Jan