zeppelin builder

Member

- Messages

- 2,133

- Location

- peoples republic of scotland

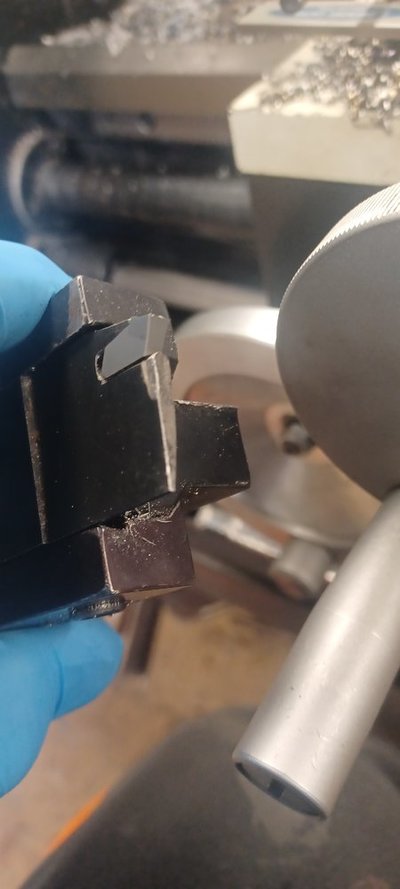

i chopped the original centre out the sprocket which had a good few reference areas i could grind it back to i didnt want to do an interupted cut with the curved parting tool .

on the new sprocket i cut a 72 mm slug out with the modded end of the iscar tool with the bed locked up and fed it with the compound then i bored it with a bar to 75 mm

i ground a prep on the weld area and tacked and welded one side , i had to turn about 3 mm out of the inside

then dug the prep out till i removed the line back to the opposite weld then welded it stick and flushed it metal bolted it up and put one wee spot on nut and the cone to secure the nut

the rear sprocket is about the size of a dinner plate so i might cut the blank with the plasma less chance of the jaws distorting the ring if its a skinny one depends what metal the original has to play with

and no im not putting 6 holes in it

the remainder of the holes allowed me to do the weld returns