inchpincher

2-stroke terror

- Messages

- 471

- Location

- Tring, UK

I've owned my Murex Tradestig 160 for about three years now and although I practised the basics in the beginning, I pretty much just pick it up now to do a job but usually walk away thinking 'it'll do but that could have been neater...'

So now I've decided to try to take it to the next level where people will say nice things about the welds and I think it's purely down to a bit of torch time and feedback from the experienced eyes on here. I've never done welding course in my life or been shown in person how to do things (although I've read and watched just about everything online!) so all comments, suggestions and tips are welcome no matter how fundamental...

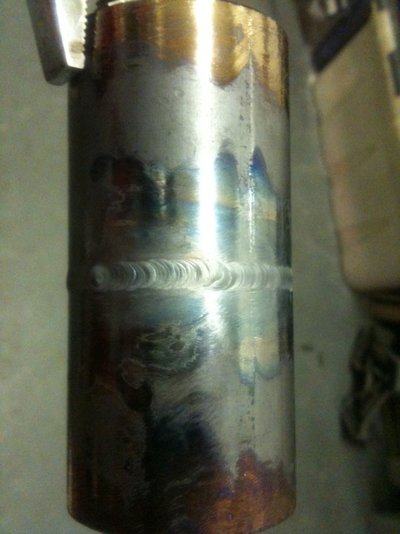

First up was a piece of 42mm CHS MS, 3mm thickness. Chopped it up on the bandsaw and set about putting it back together. Penetration I was happy with although I got some sag from where I was starting a new bead and back stepped the torch to get rid of the ugly mound of filler from the previous beads end. I think this was down from practising Ali recently where I fill the puddle with filler as the bead ends to stop a crater forming... Comments? Consistency of arc length going around the tube was the part I feel needs the most improvement

So now I've decided to try to take it to the next level where people will say nice things about the welds and I think it's purely down to a bit of torch time and feedback from the experienced eyes on here. I've never done welding course in my life or been shown in person how to do things (although I've read and watched just about everything online!) so all comments, suggestions and tips are welcome no matter how fundamental...

First up was a piece of 42mm CHS MS, 3mm thickness. Chopped it up on the bandsaw and set about putting it back together. Penetration I was happy with although I got some sag from where I was starting a new bead and back stepped the torch to get rid of the ugly mound of filler from the previous beads end. I think this was down from practising Ali recently where I fill the puddle with filler as the bead ends to stop a crater forming... Comments? Consistency of arc length going around the tube was the part I feel needs the most improvement

-

C053674C-C6EA-47CF-A63A-BD719657914D-722-000001196CD3B176_zps89333773.jpg57.7 KB · Views: 608

C053674C-C6EA-47CF-A63A-BD719657914D-722-000001196CD3B176_zps89333773.jpg57.7 KB · Views: 608 -

367074BA-4CFD-4F27-8131-0D4F5446B946-722-000001198F00AE16_zps975d15ba.jpg47.1 KB · Views: 606

367074BA-4CFD-4F27-8131-0D4F5446B946-722-000001198F00AE16_zps975d15ba.jpg47.1 KB · Views: 606 -

81DD8EE8-B97E-445C-AAB4-D199472E2F19-722-00000119B3082BA3_zps90e64c85.jpg91.3 KB · Views: 611

81DD8EE8-B97E-445C-AAB4-D199472E2F19-722-00000119B3082BA3_zps90e64c85.jpg91.3 KB · Views: 611 -

9F31D290-5C56-4777-BD27-931B7D8C30E9-722-00000119BC628264_zps4da43c41.jpg98 KB · Views: 608

9F31D290-5C56-4777-BD27-931B7D8C30E9-722-00000119BC628264_zps4da43c41.jpg98 KB · Views: 608 -

3AECB7AB-AE23-41A2-8AD3-6117D0BAC9CA-722-00000119D0BFB21A_zpse198e0c9.jpg101.3 KB · Views: 613

3AECB7AB-AE23-41A2-8AD3-6117D0BAC9CA-722-00000119D0BFB21A_zpse198e0c9.jpg101.3 KB · Views: 613 -

B081C716-370A-4990-BA0A-B5A87417DB92-722-00000119C4D003A4_zpsf56ce67c.jpg63.2 KB · Views: 608

B081C716-370A-4990-BA0A-B5A87417DB92-722-00000119C4D003A4_zpsf56ce67c.jpg63.2 KB · Views: 608

I'm useless at pipe!

I'm useless at pipe!