rob passfield

New Member

- Messages

- 6

- Location

- colchester

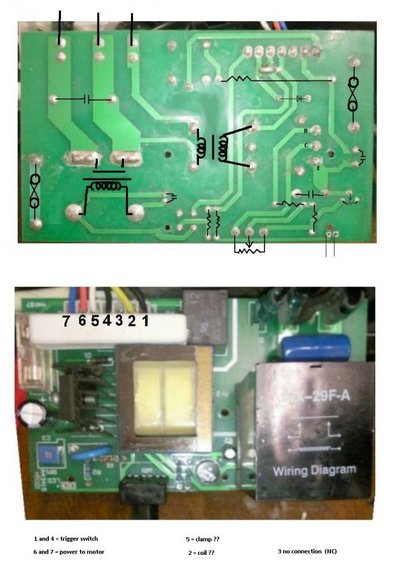

Hi all, I need some thoughts on a wire feed problem I am having with my Kende 150. Problems started recently welding new spring boxes into my MG Midget. When using the handset without any twists or bends the welder works ok, but with a little more splatter than before. But when any slight bend or twist in the hose, wire continuously burns back to the tip of the contact tip. I have renewed the liner, changed the contact tips, checked connections at the mains plug & internal cables. I have observed the wire feed without making an arc & all looks smooth & without snagging, but as soon as the arc is struck the burn back is apparent. I have tried another spool of 0.6 wire, no change. Someone has suggested a new grooved roller in the wire feed? What do you think? Any help would be welcome. The wire feed is similar to the sealey mightymig 150.