- Messages

- 17,533

Had this for a good few years and other than a knob that broke a few years ago it's been absolutely faultless until recently.

Every now and again while drilling, the bit would stop spinning even though the motor was working fine.

Easing the pressure on the bit would sometimes get it to spin just enough to retrieve it from the hole, fortunately everything I've been drilling lately has been to weaken it ready to break it up so if a bit got stuck I could always retrieve it eventually.

Thought I'd try and see if I could find out what was wrong with it so set about it with my tools this morning.

Before starting (obviously):

Casing removal pt1:

Motor housing off:

Casing removal pt2:

"Nose piece" removal:

This is the piston which creates the hammer action. For those unfamiliar with how these work, this piston travels back and forth inside a bore, the air it displaces causes another loose piston to strike a flat ended thingy (can't think of the best word to describe it) which is attached to the opposite end of the chuck.

The actual piston and conrod:

For anyone wincing at the above photo, the vice isn't done up tight, it's just very lightly nipped up to hold the motor upright.

Gearbox split:

The pin inside the gear on the right disengages the hammer action when that black plastic lever is flipped, it pushes up inside the bore in the photo below

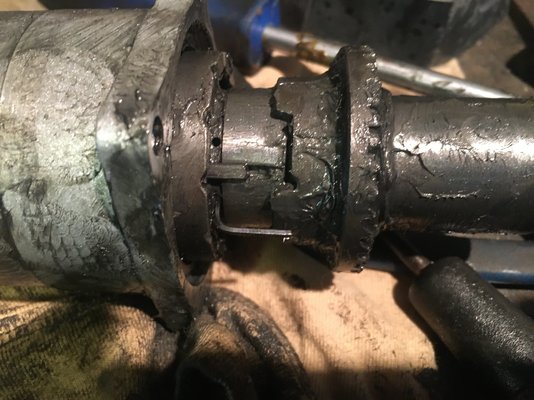

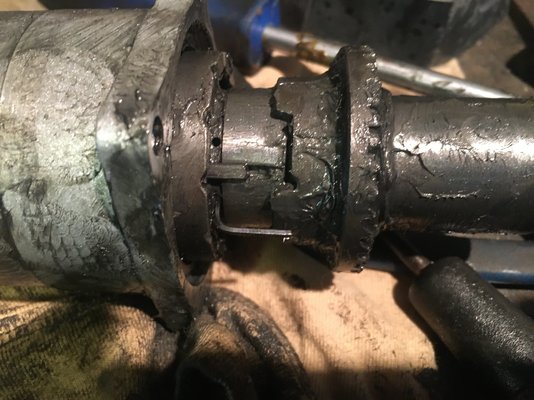

The business end:

^This is the mechanism to engage/disengage the rotation. As it's shown there, the rotation would be disengaged, it's held together by a spring and those cutouts on the left side of that gear.

Annoyingly I couldn't find anything obviously wrong with it but I regreased and reassembled everything and upon testing it does seem to be working fine though I'll know more when I put it to proper use again.

If it happens again I suspect it might be something inside the nose piece so will attempt to strip that part down further, it may even be a piece of grit or something causing the rotation stop mechanism to stick disengaged.

Every now and again while drilling, the bit would stop spinning even though the motor was working fine.

Easing the pressure on the bit would sometimes get it to spin just enough to retrieve it from the hole, fortunately everything I've been drilling lately has been to weaken it ready to break it up so if a bit got stuck I could always retrieve it eventually.

Thought I'd try and see if I could find out what was wrong with it so set about it with my tools this morning.

Before starting (obviously):

Casing removal pt1:

Motor housing off:

Casing removal pt2:

"Nose piece" removal:

This is the piston which creates the hammer action. For those unfamiliar with how these work, this piston travels back and forth inside a bore, the air it displaces causes another loose piston to strike a flat ended thingy (can't think of the best word to describe it) which is attached to the opposite end of the chuck.

The actual piston and conrod:

For anyone wincing at the above photo, the vice isn't done up tight, it's just very lightly nipped up to hold the motor upright.

Gearbox split:

The pin inside the gear on the right disengages the hammer action when that black plastic lever is flipped, it pushes up inside the bore in the photo below

The business end:

^This is the mechanism to engage/disengage the rotation. As it's shown there, the rotation would be disengaged, it's held together by a spring and those cutouts on the left side of that gear.

Annoyingly I couldn't find anything obviously wrong with it but I regreased and reassembled everything and upon testing it does seem to be working fine though I'll know more when I put it to proper use again.

If it happens again I suspect it might be something inside the nose piece so will attempt to strip that part down further, it may even be a piece of grit or something causing the rotation stop mechanism to stick disengaged.