Toscane

Member

- Messages

- 43

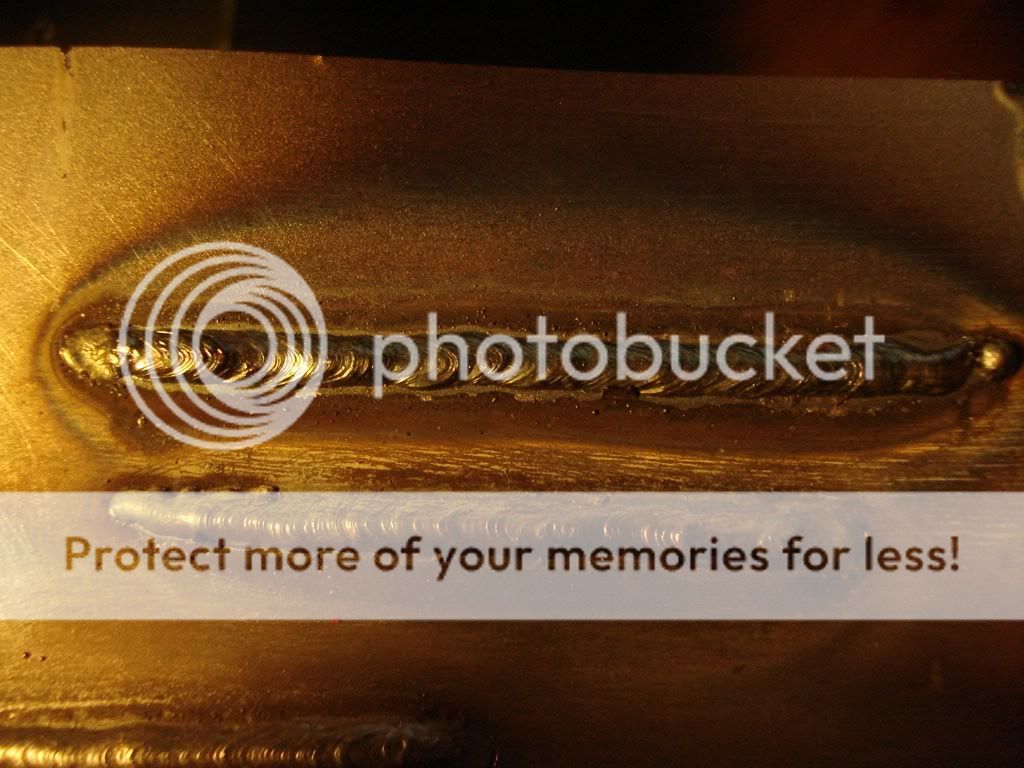

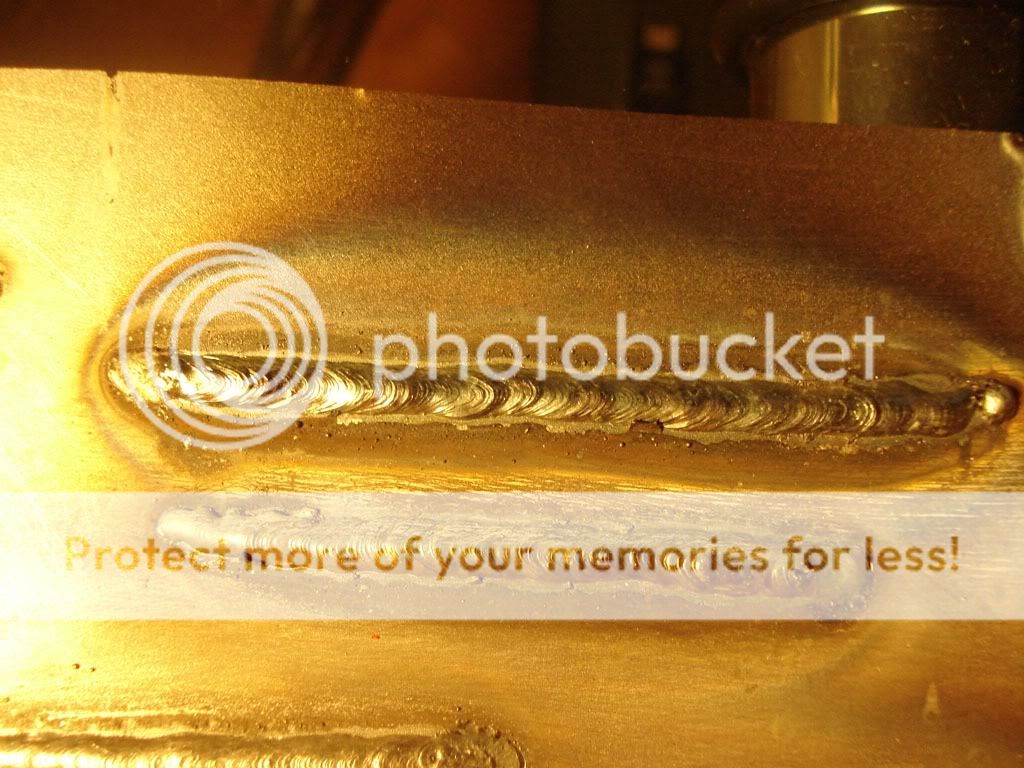

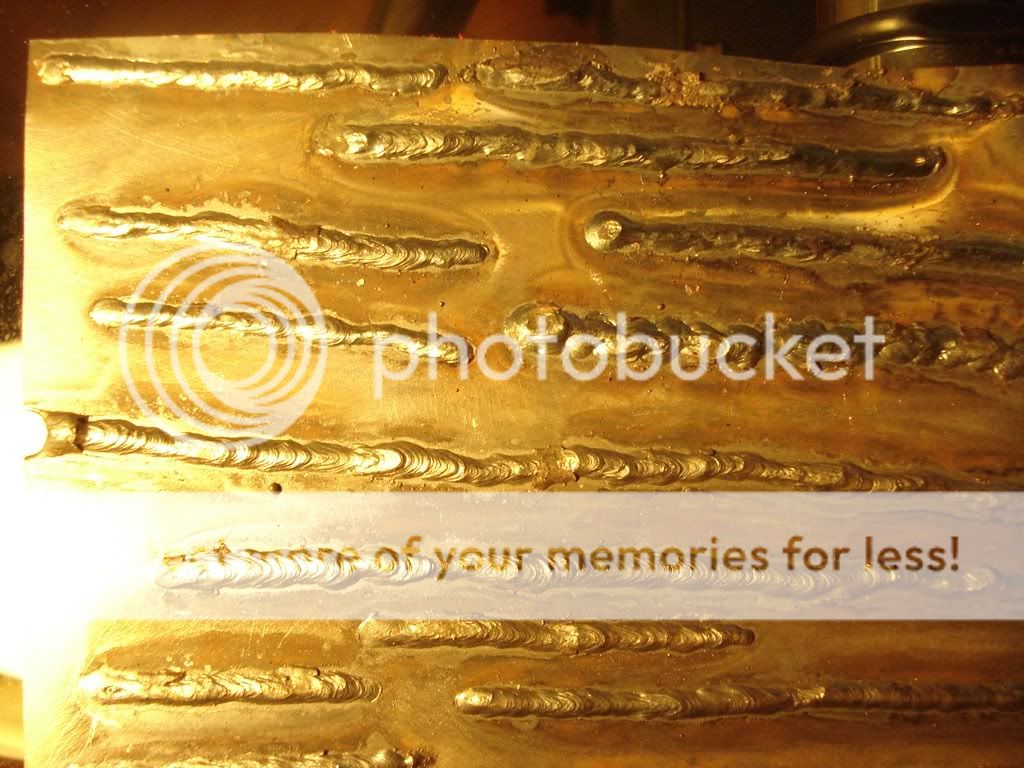

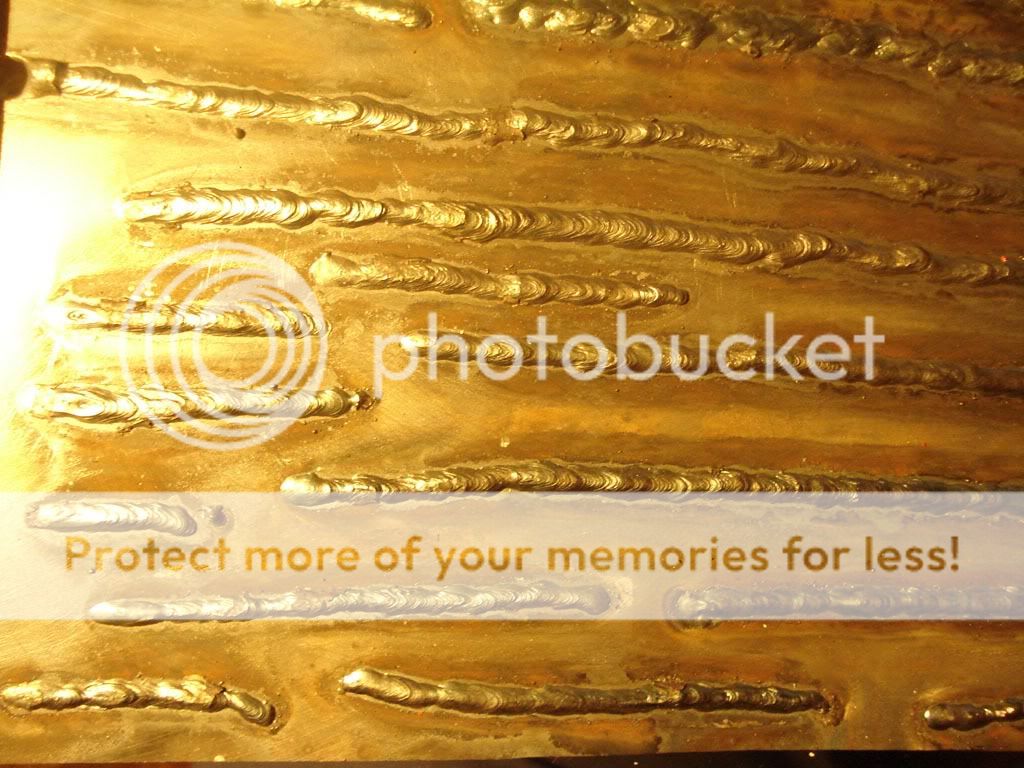

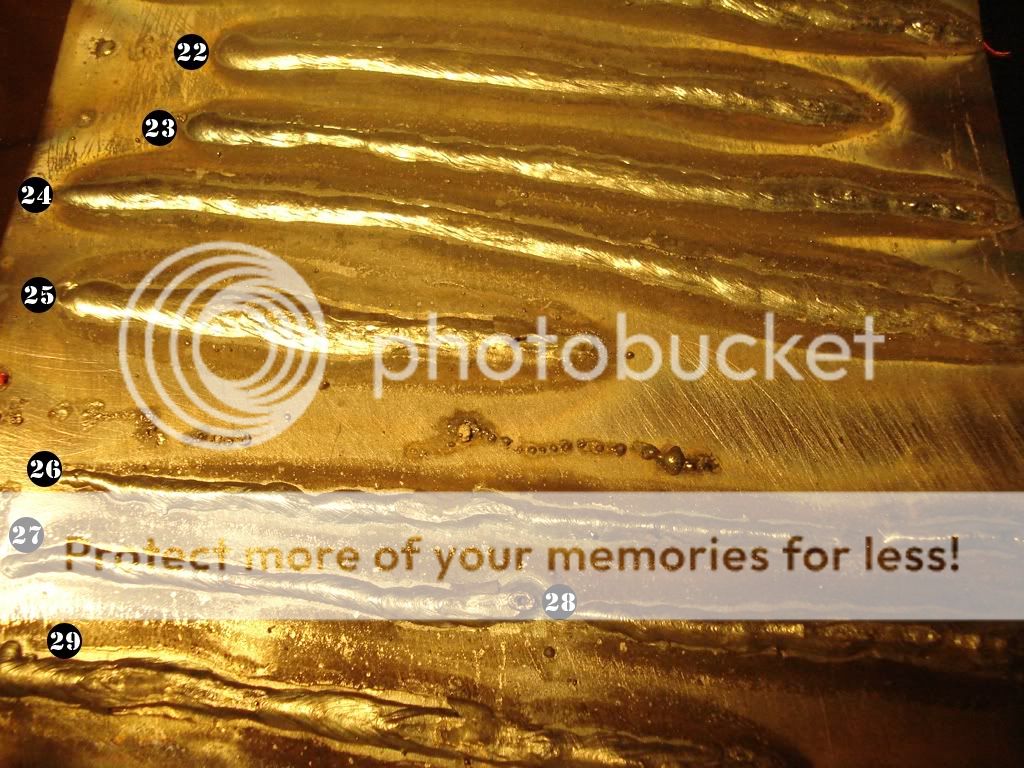

Here is the photographic evidence of my very first stick welding attempts. I am going to keep posting pictures of my welds in this thread so I can get feedback from more experienced users and improve my technique.

Also it might be useful for the beginners in the future...

...or not.

Anyways, here we go.

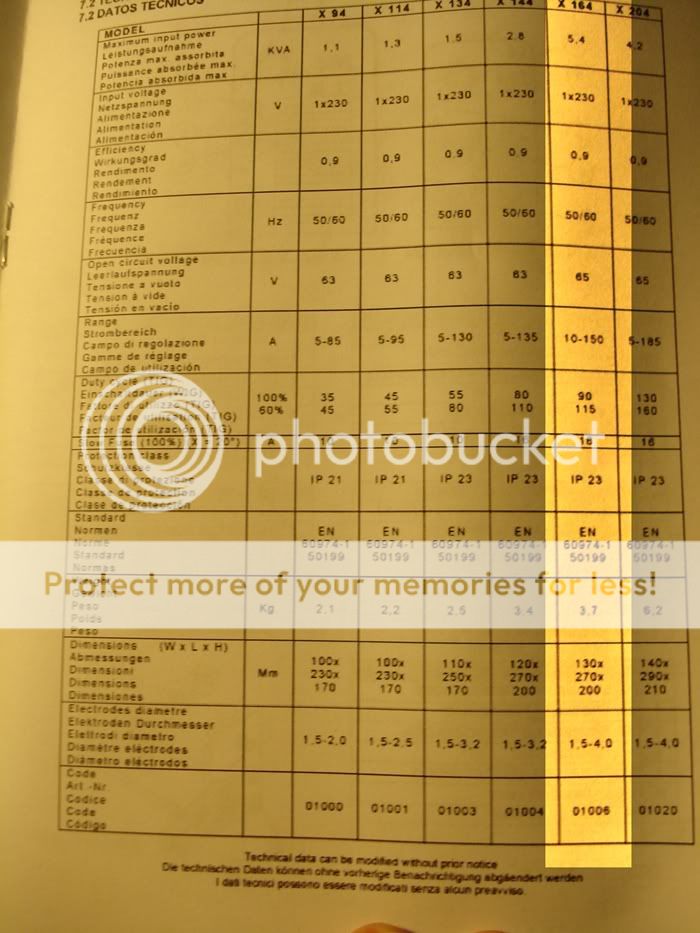

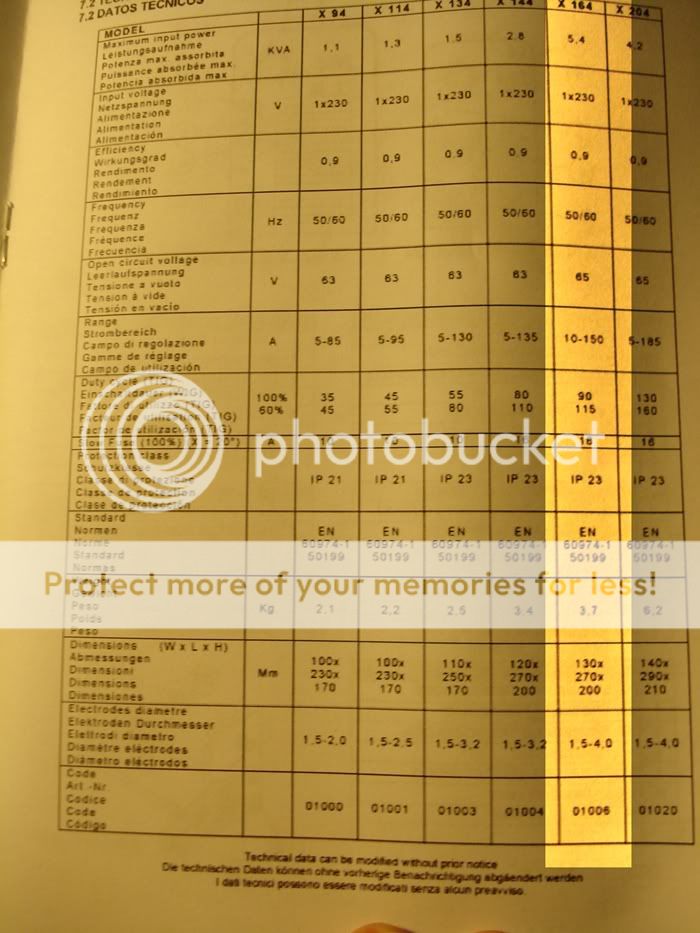

Welding Machine: I am using a small inverter but I don't know if its DC or AC, can't be both right? So I'm posting the specifications of my inverter as a first picture.

Rods: I couldn't find anything other than some domestic brand which is manufactured where I live, made in a factory about 2 hours away from me so I'm stuck with them. They are called Oerlikon and I got the Overcord-S model, 2.00x300 dimensions, 6013.

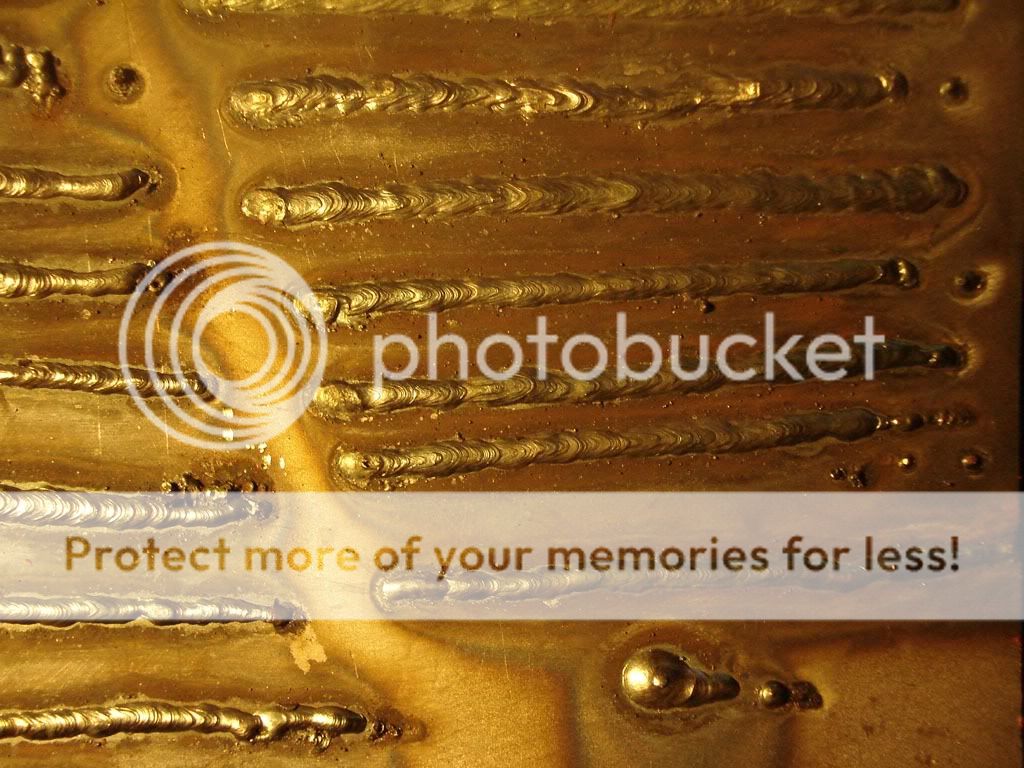

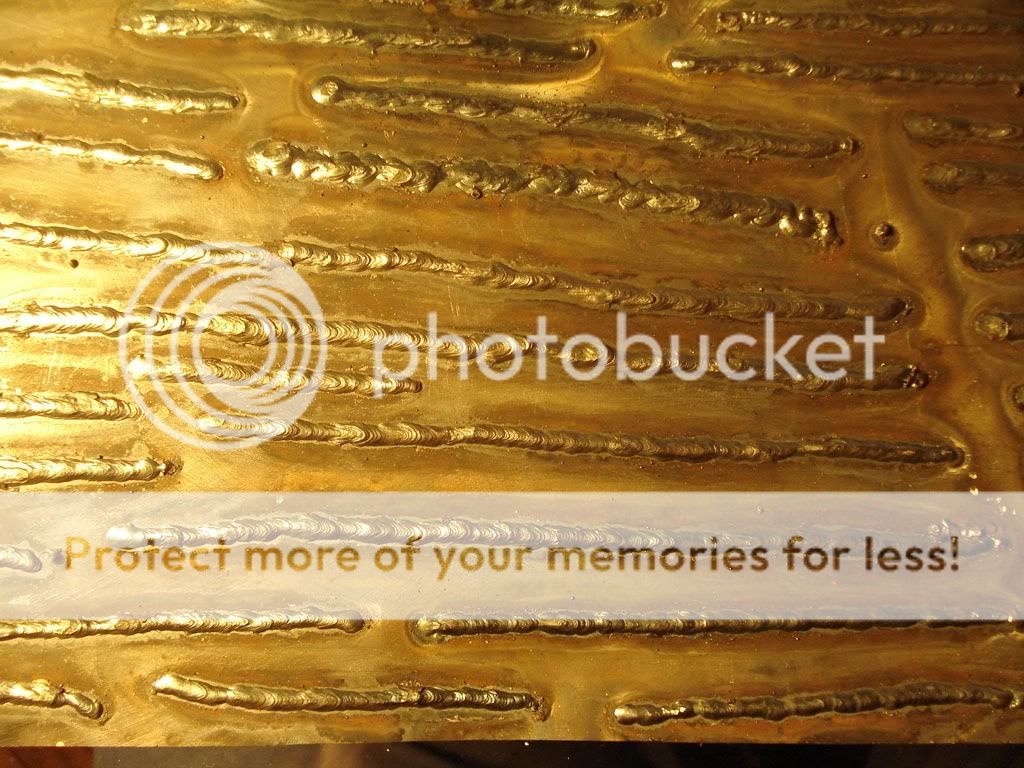

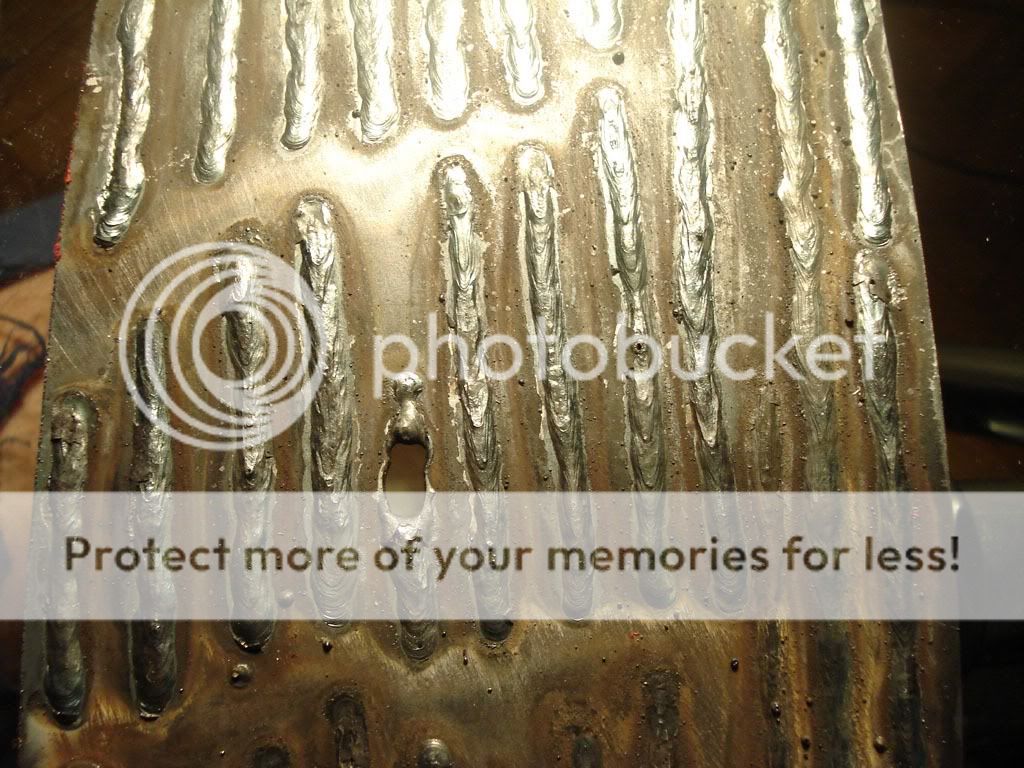

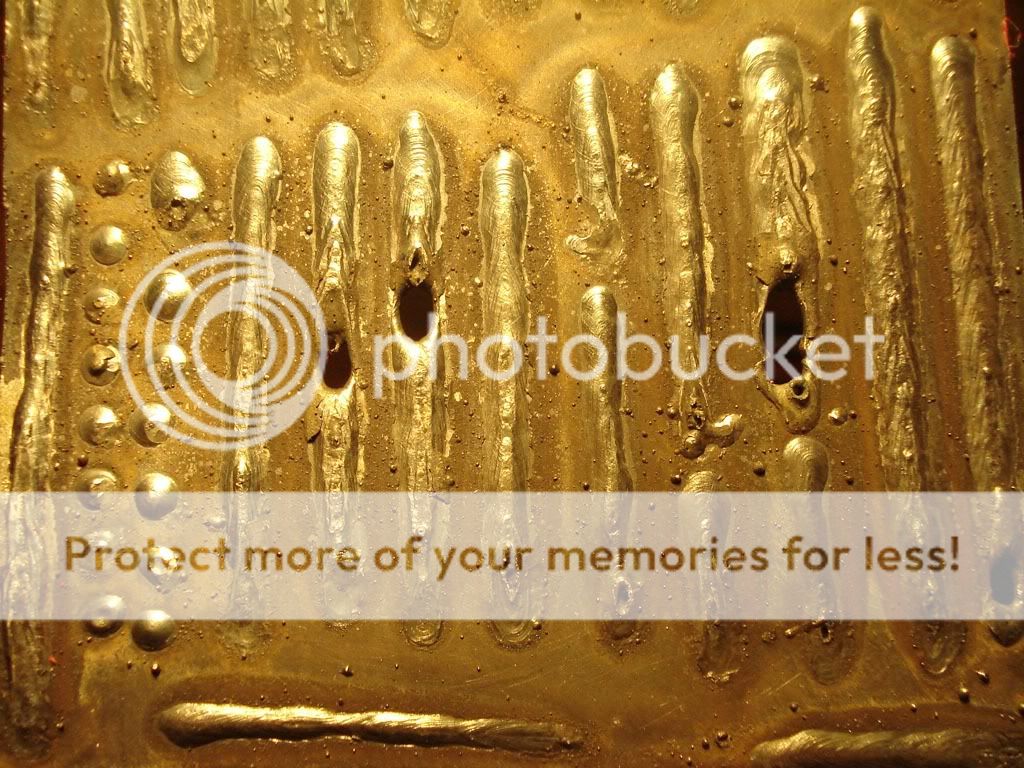

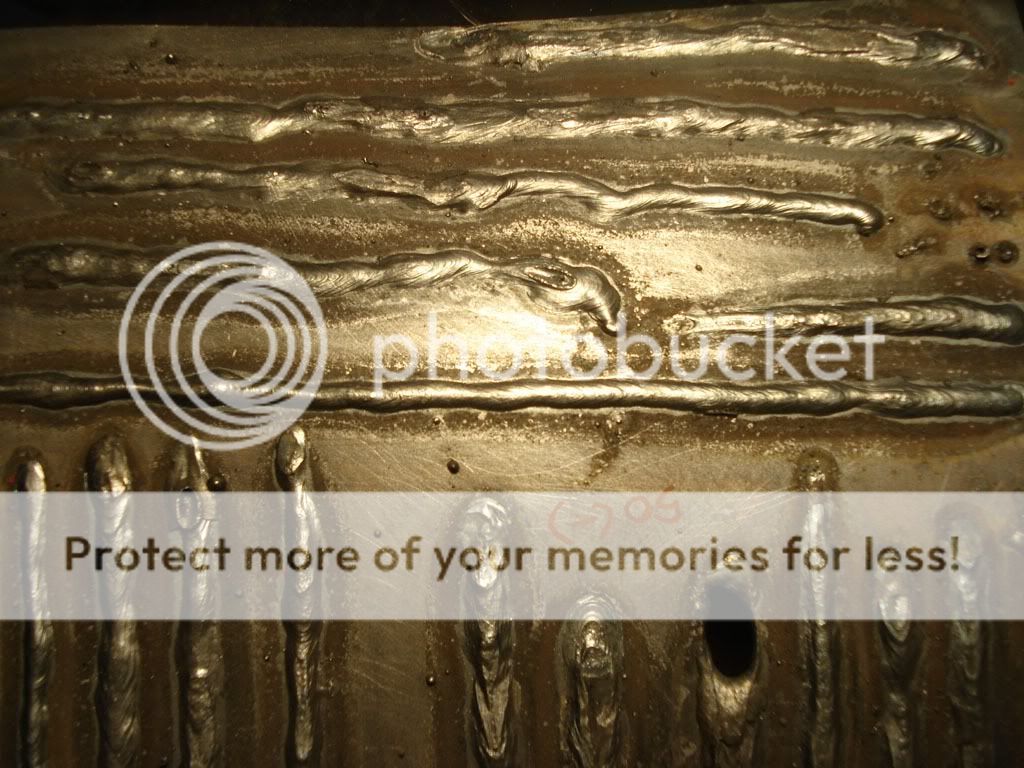

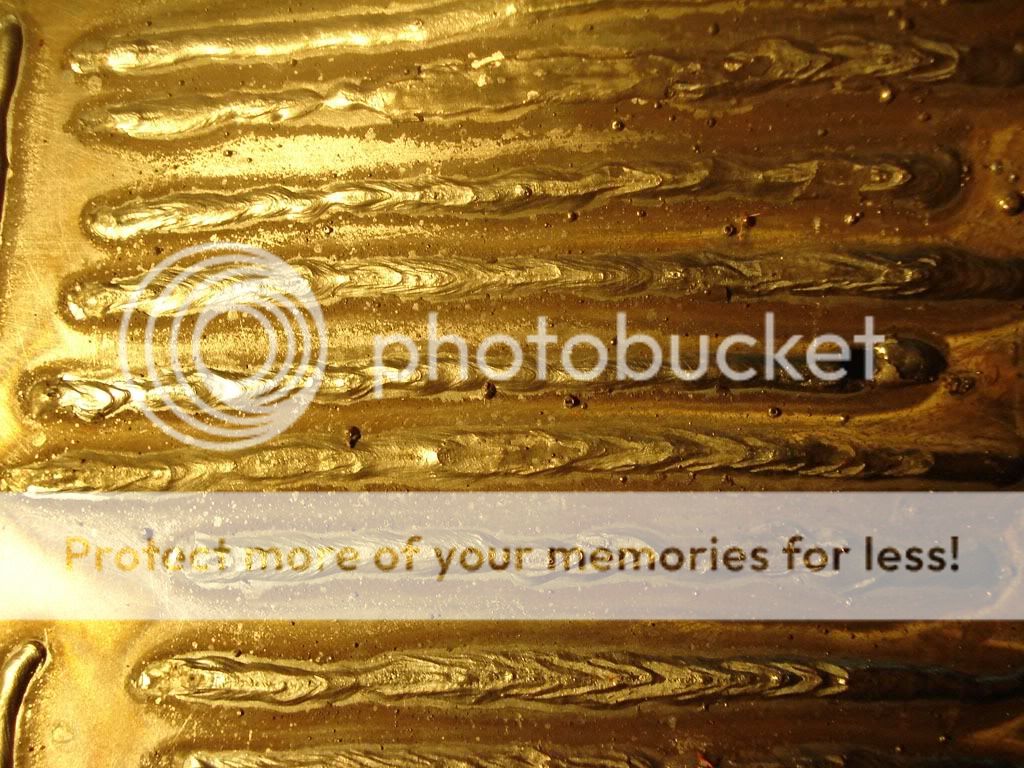

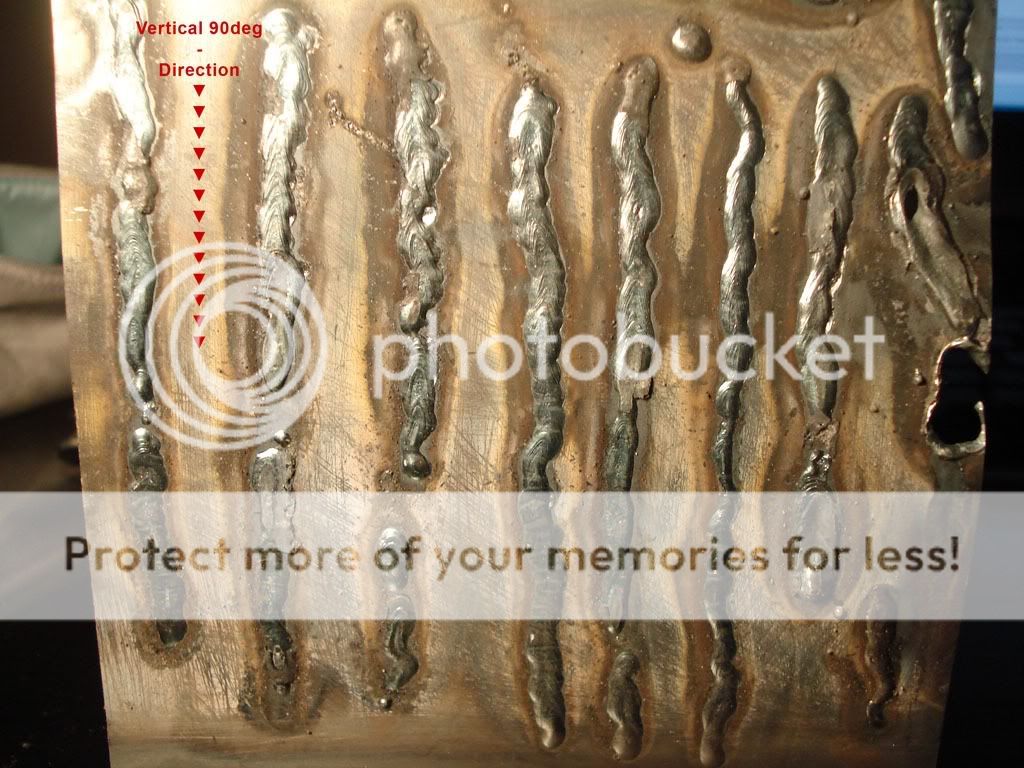

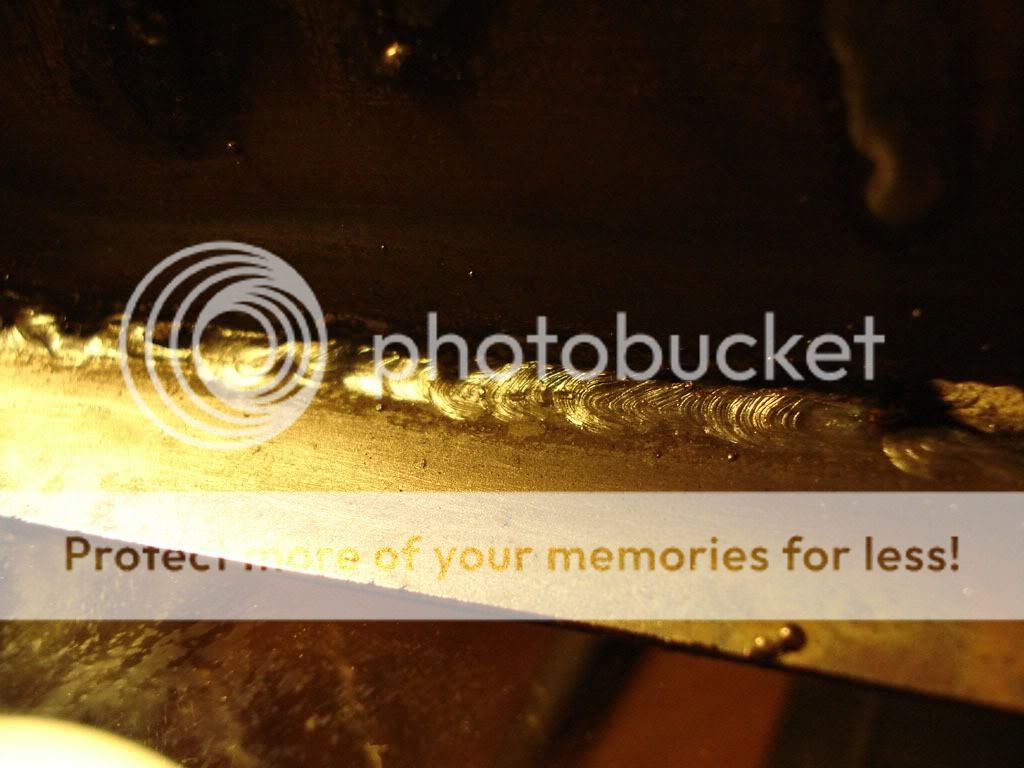

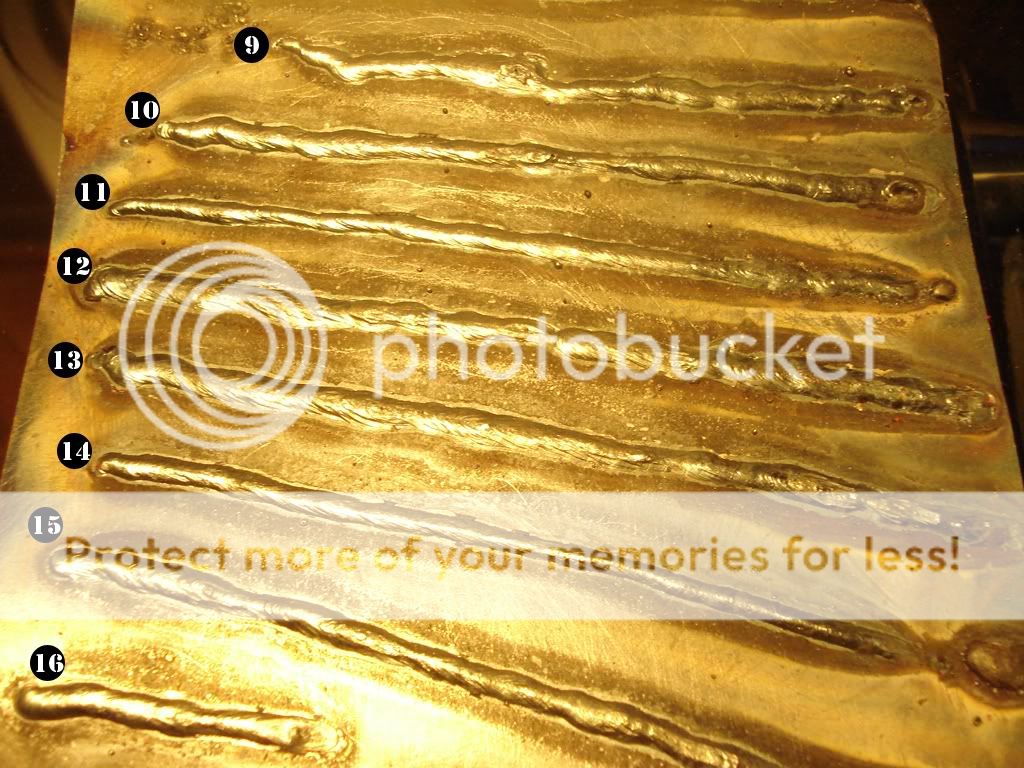

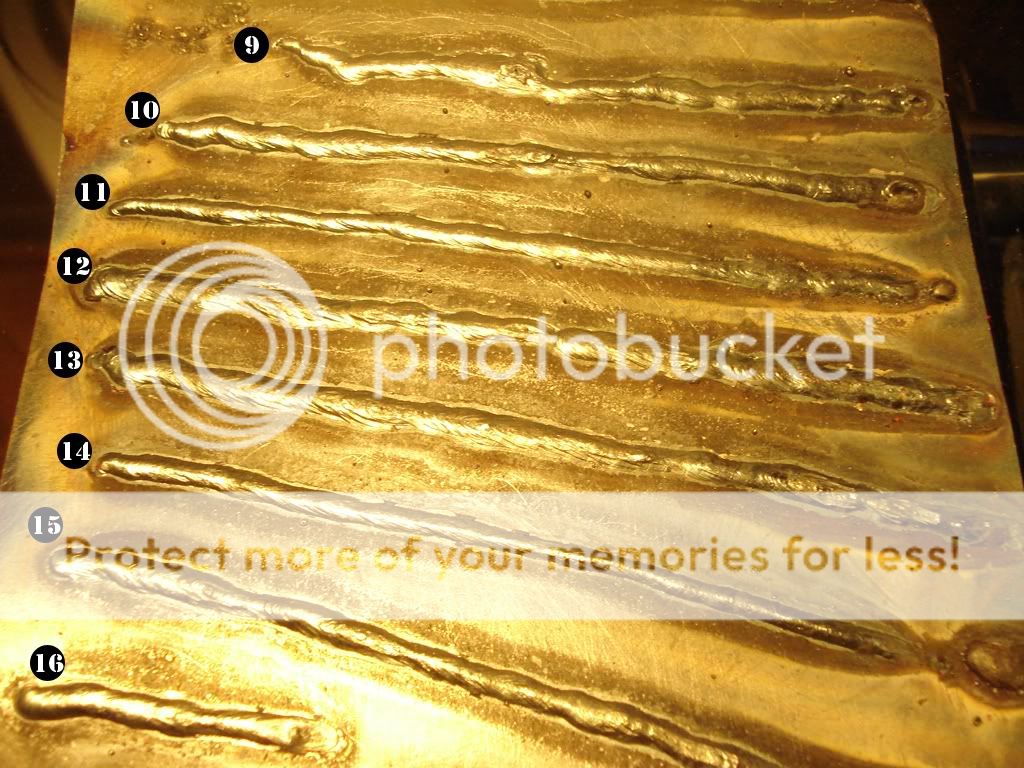

1.2mm sheet metal, setting 40-50, welder (+):

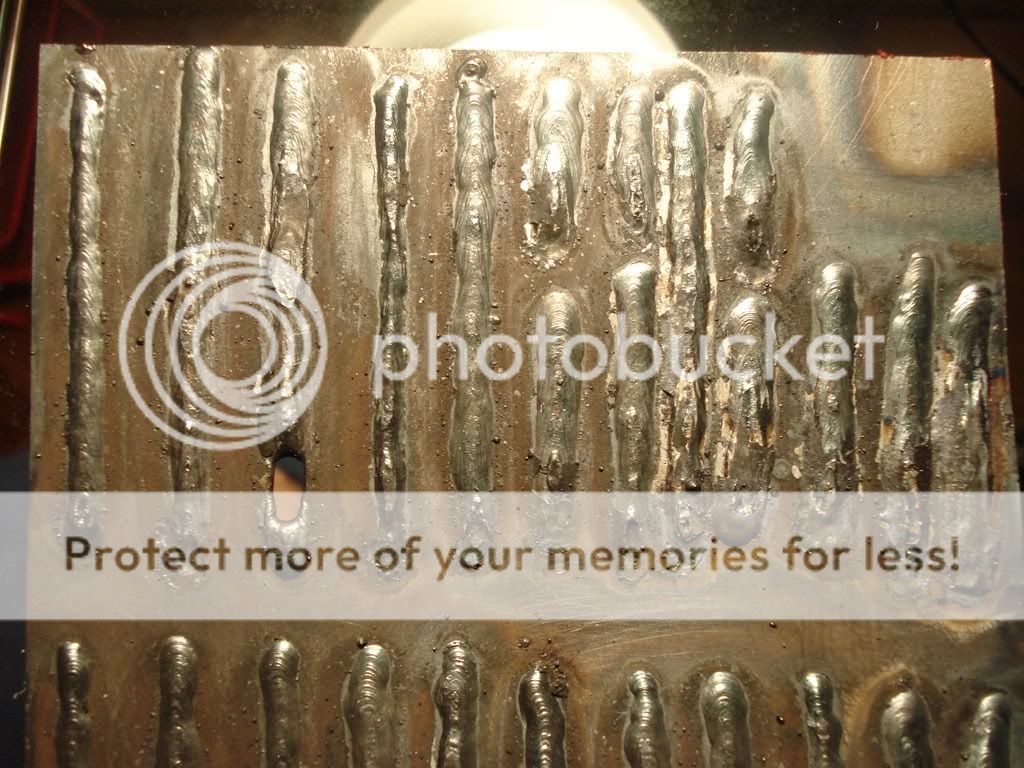

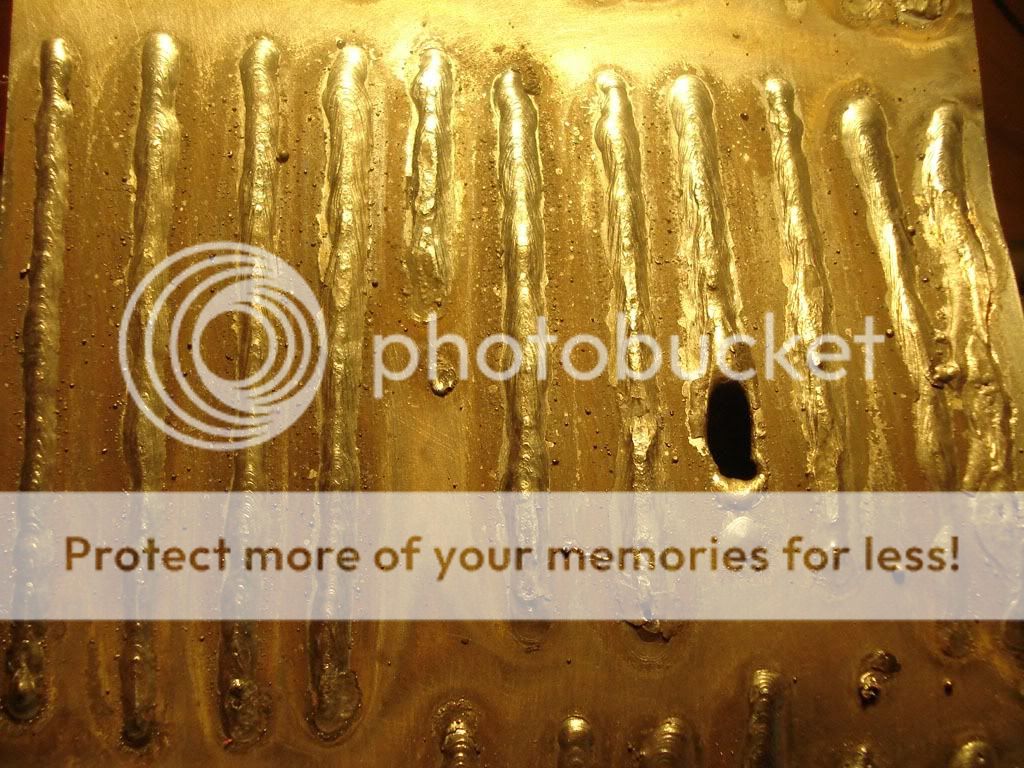

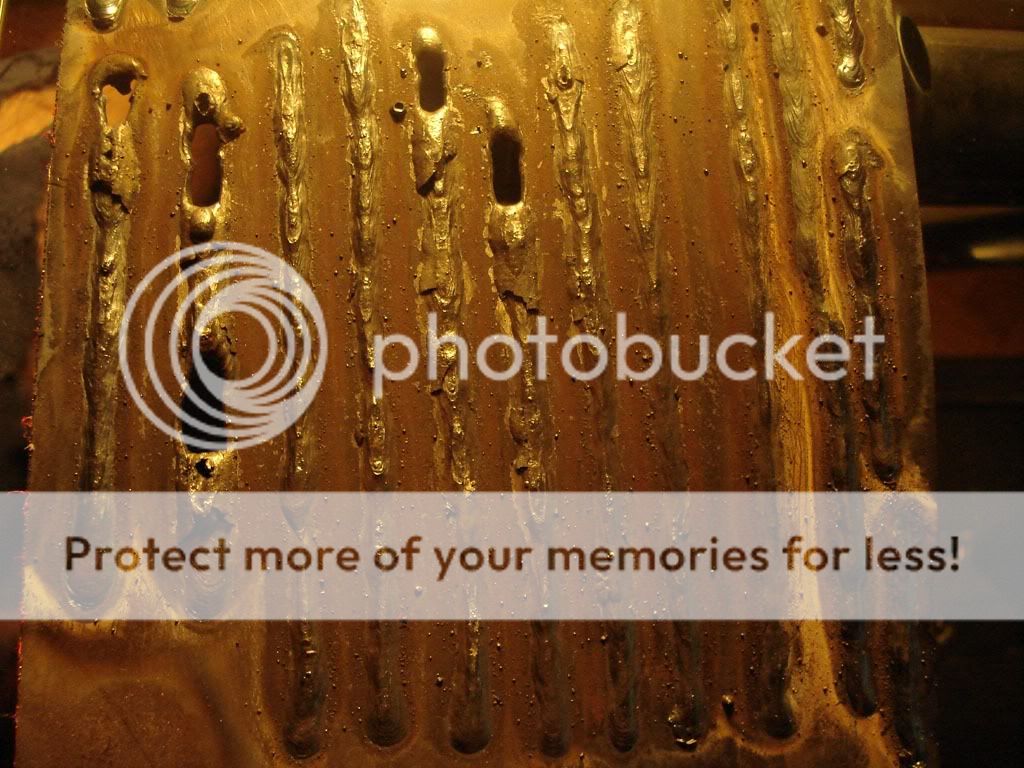

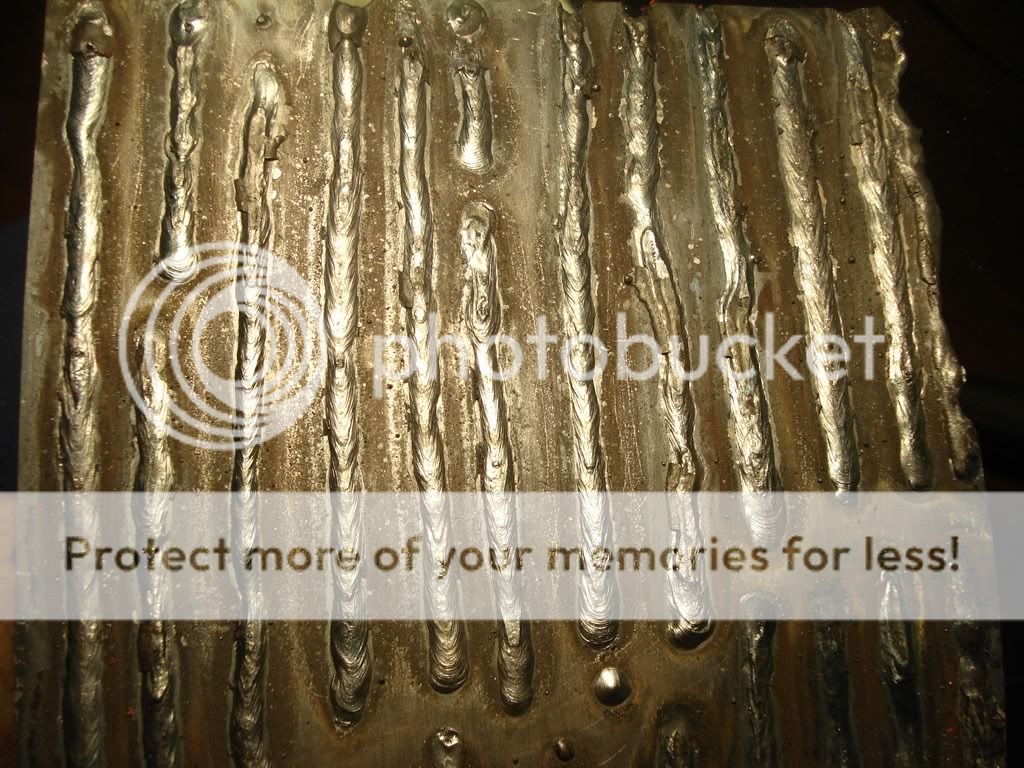

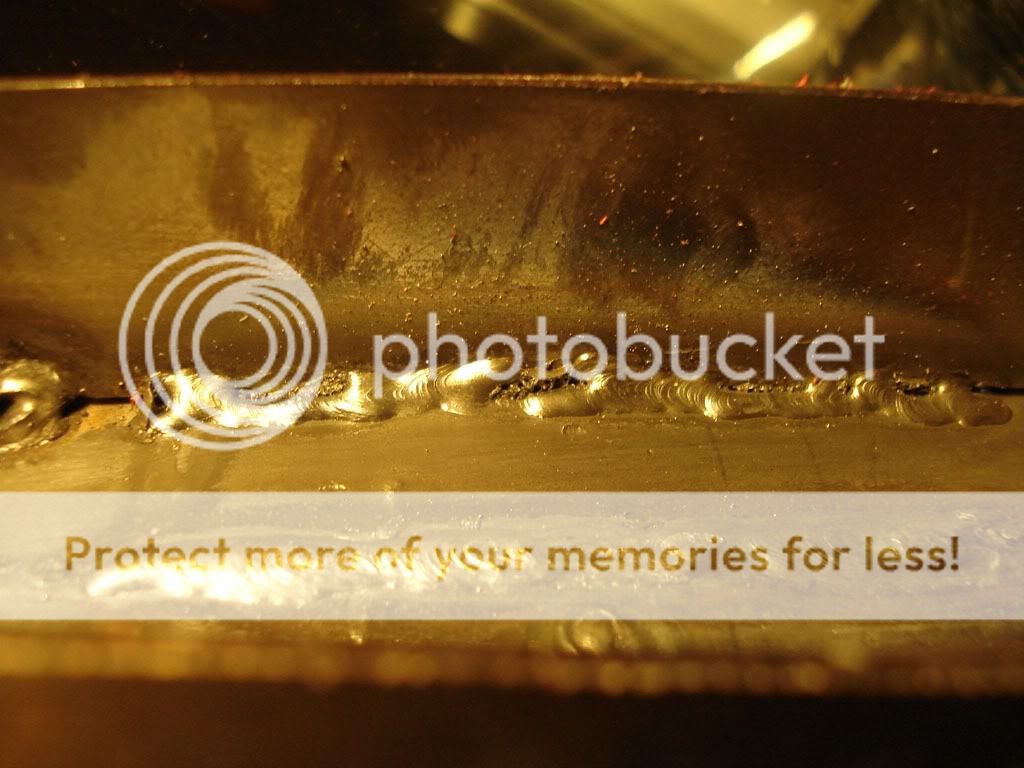

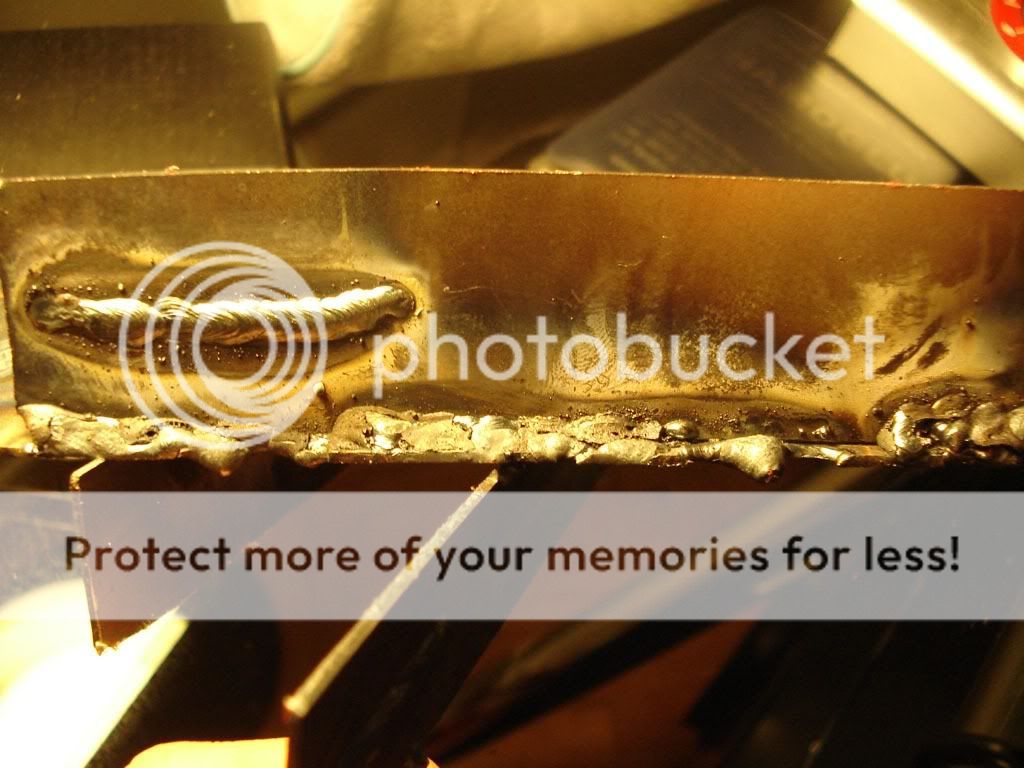

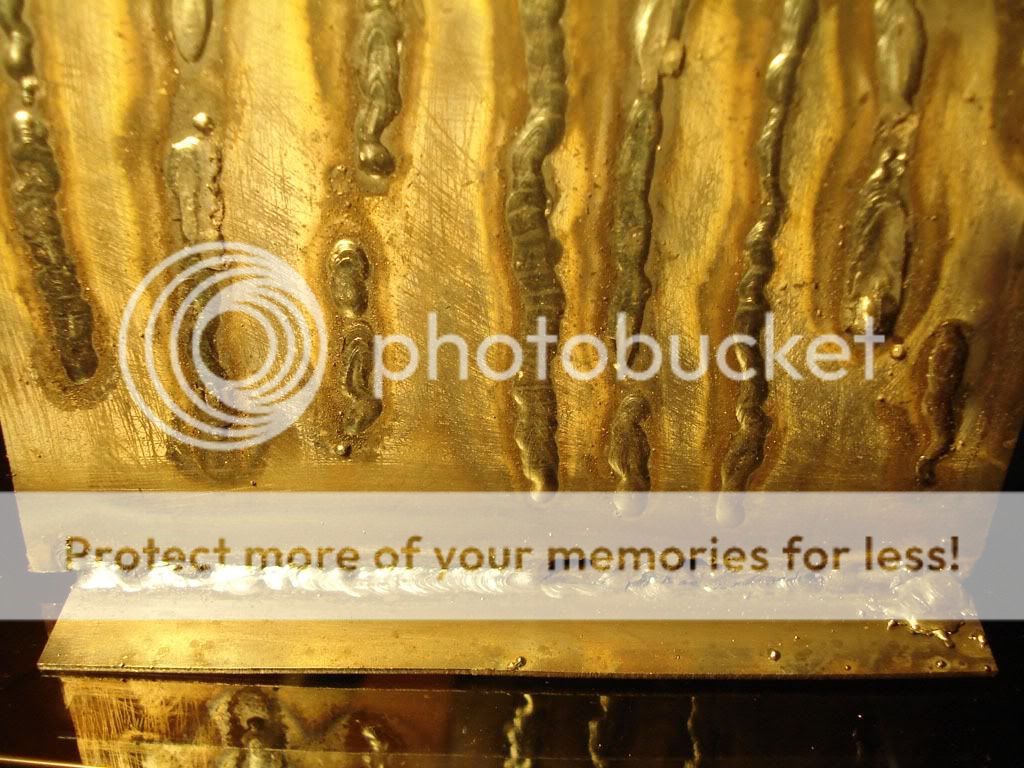

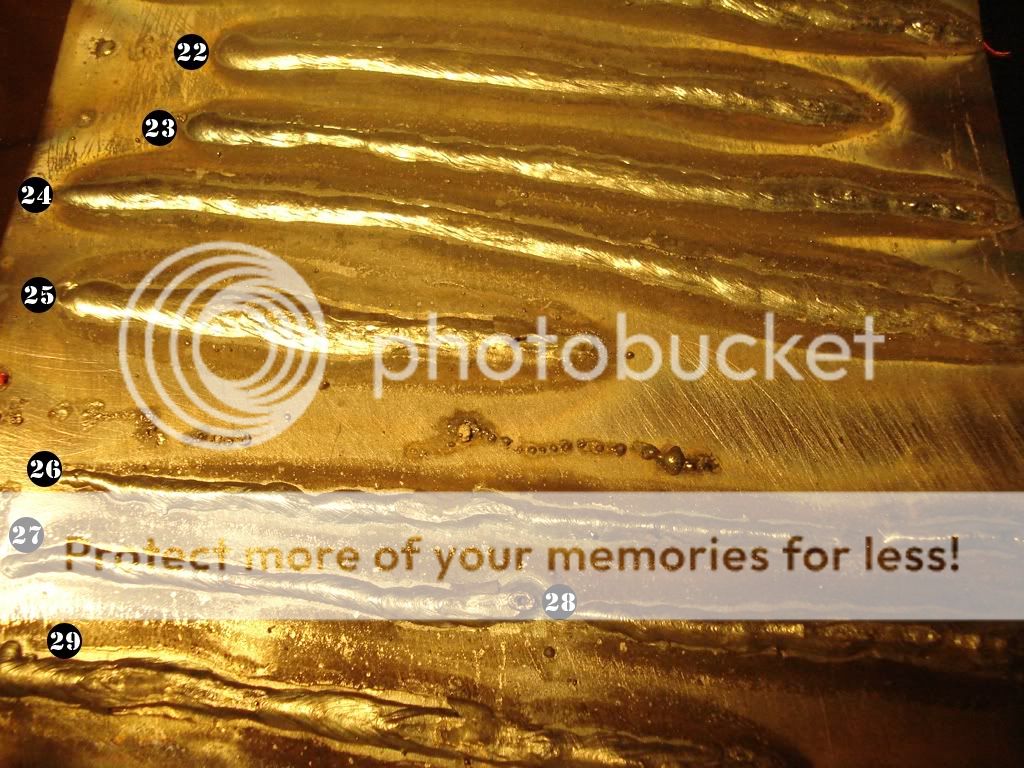

As you can see in the last 2 pictures, sheet metal warped very badly; it was as flat as Calista Flockhart's chest in the beginning. I guess I need to take it slow on her, she can't handle too much heat I assume.

Oh and I can go as thick as 1.5mm sheet metal, if I push it too much I can get 2.0mm but that, will hurt. I know it's hard to stick weld thin metal but I have to nail it, soon.

Okay, now your turn people, what do you think?

P.S. Stick welding is absolute fun! It's very addicting and sensation of feeling the heat, electric and burning metal is incredible! It's 2 AM and I'm waiting for the damn rain to stop so I can go outside and continue!

I'm so happy I got in this, I love my stick! It's so fun to spend time with it!

Also it might be useful for the beginners in the future...

...or not.

Anyways, here we go.

Welding Machine: I am using a small inverter but I don't know if its DC or AC, can't be both right? So I'm posting the specifications of my inverter as a first picture.

Rods: I couldn't find anything other than some domestic brand which is manufactured where I live, made in a factory about 2 hours away from me so I'm stuck with them. They are called Oerlikon and I got the Overcord-S model, 2.00x300 dimensions, 6013.

1.2mm sheet metal, setting 40-50, welder (+):

As you can see in the last 2 pictures, sheet metal warped very badly; it was as flat as Calista Flockhart's chest in the beginning. I guess I need to take it slow on her, she can't handle too much heat I assume.

Oh and I can go as thick as 1.5mm sheet metal, if I push it too much I can get 2.0mm but that, will hurt. I know it's hard to stick weld thin metal but I have to nail it, soon.

Okay, now your turn people, what do you think?

P.S. Stick welding is absolute fun! It's very addicting and sensation of feeling the heat, electric and burning metal is incredible! It's 2 AM and I'm waiting for the damn rain to stop so I can go outside and continue!

I'm so happy I got in this, I love my stick! It's so fun to spend time with it!