MichaelV

Member

- Messages

- 242

- Location

- Co. Antrim

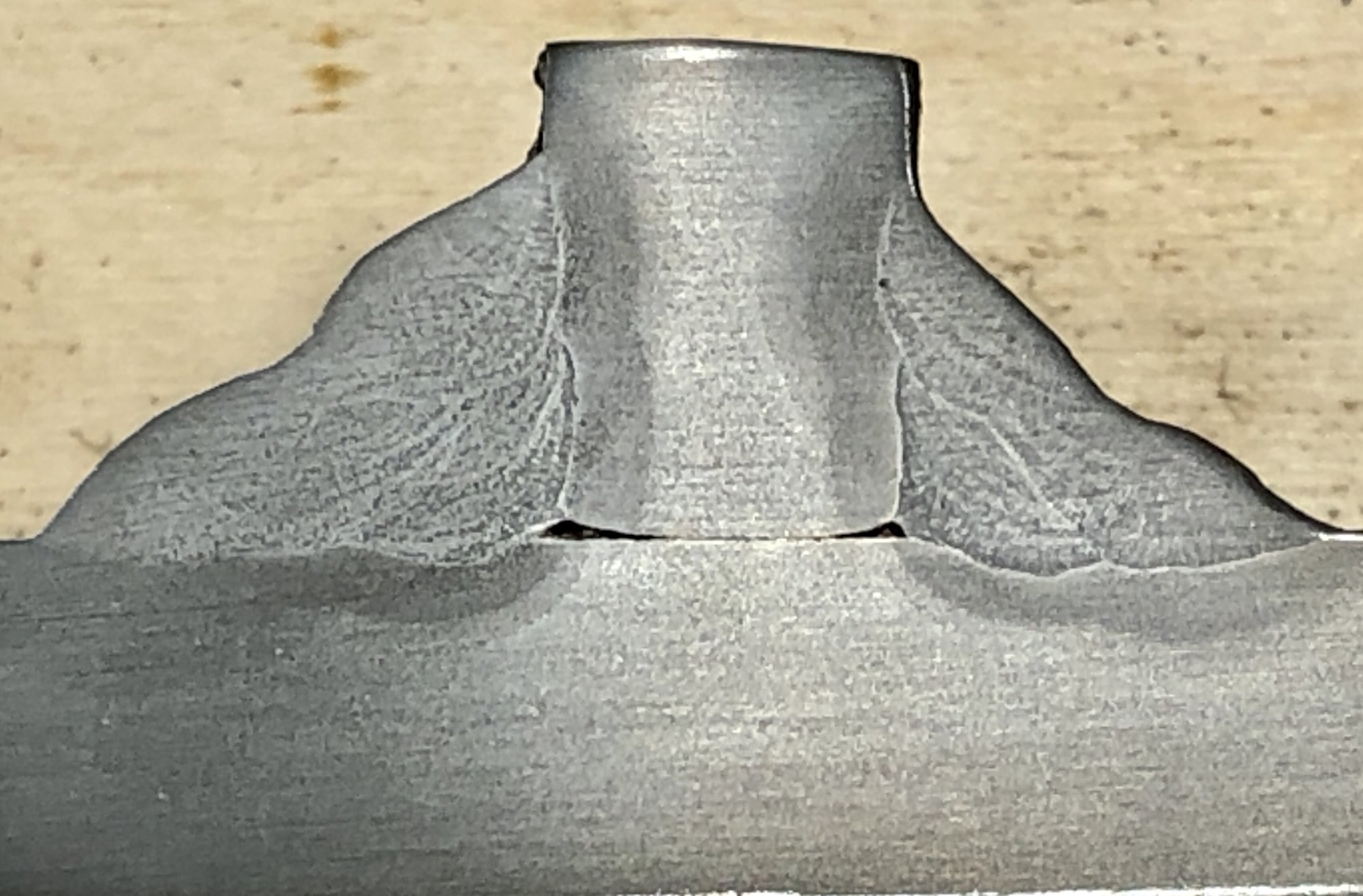

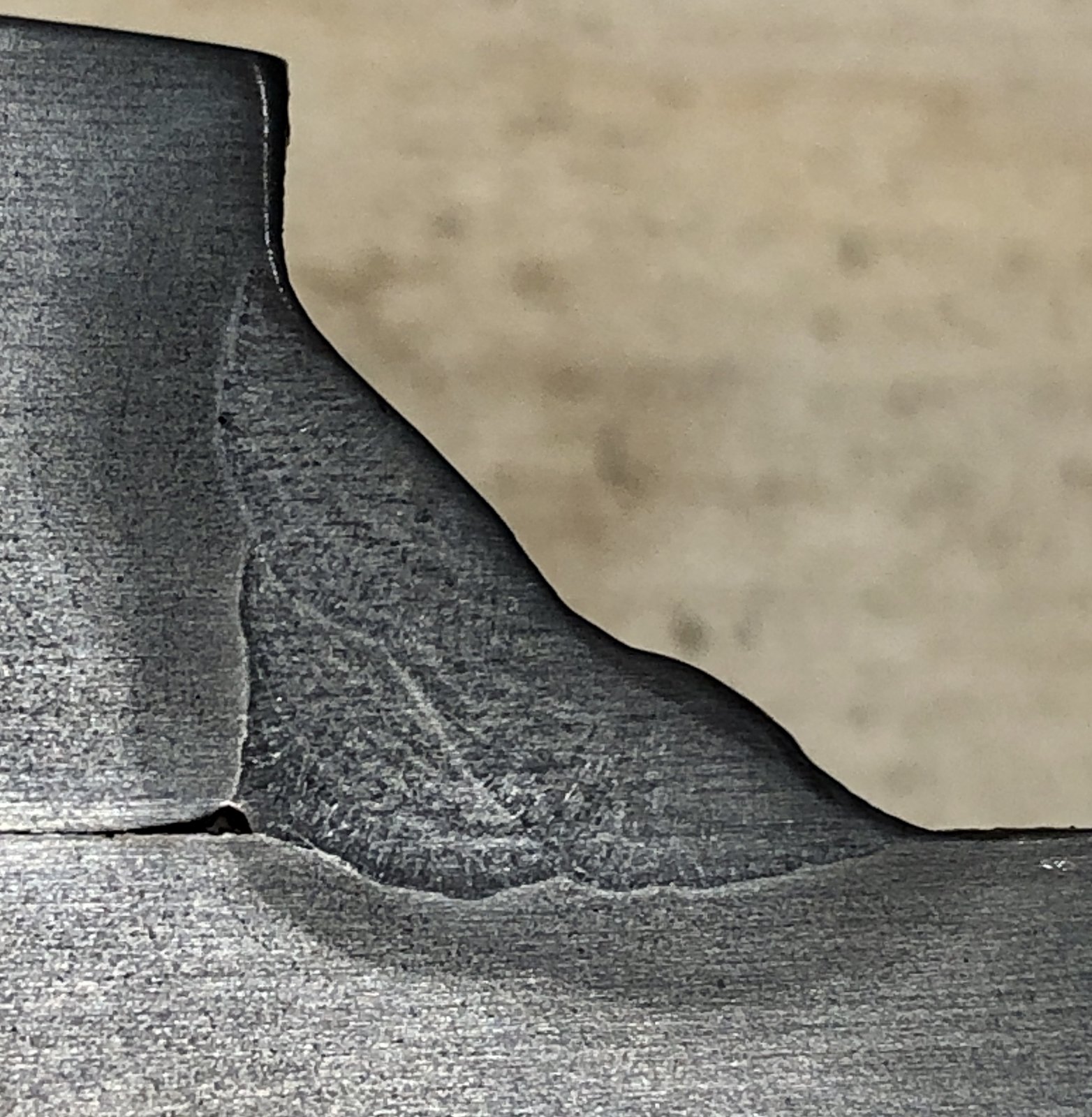

This time, 7018...

Position & material:

PB (2F), tee joint between 10 mm thick mild steel, rolled flat bars with rolled edges. Cut from same bar as used in all other Parts.

Parameters:

3 or 4 passes each side with 3.2 mm, 7018 (Elga P48M), DC positive, 125A, zero arc force. Passes were made on alternating basis. The rods were not baked or prepared in any way, and have been stored in a rod tube, following opening of the original vacpac months ago.

Remarks:

Satisfactory, if not very deep penetration. The root runs would perhaps be better with 2.5mm rods, but none are to hand. Again, the complete absence of ‘dig’ might be a factor. That’s the variable to be tested in Part 6

Michael

Position & material:

PB (2F), tee joint between 10 mm thick mild steel, rolled flat bars with rolled edges. Cut from same bar as used in all other Parts.

Parameters:

3 or 4 passes each side with 3.2 mm, 7018 (Elga P48M), DC positive, 125A, zero arc force. Passes were made on alternating basis. The rods were not baked or prepared in any way, and have been stored in a rod tube, following opening of the original vacpac months ago.

Remarks:

Satisfactory, if not very deep penetration. The root runs would perhaps be better with 2.5mm rods, but none are to hand. Again, the complete absence of ‘dig’ might be a factor. That’s the variable to be tested in Part 6

Michael