hotponyshoes

Member

- Messages

- 6,417

- Location

- Somerset. Uk

I need to do some long runs on 2mm aluminium sheet.

Planning to use pulse mig,

Normally I would set it up inside corner to inside corner so I have 2x 2mm faces to weld against.

In this case I would like some location tabs/slots cut into the sheets which rules out corner to corner setup.

So I have a few options,

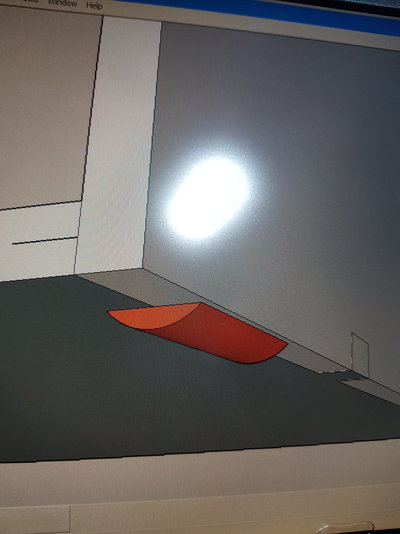

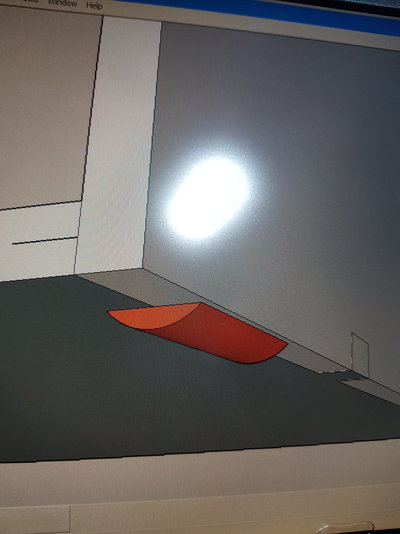

Recess the slots for the tabs by 1mm so I am left with a 1mm face to weld against a 2mm face (red=weld bead)

Recess the slots by 2mm and run along the face

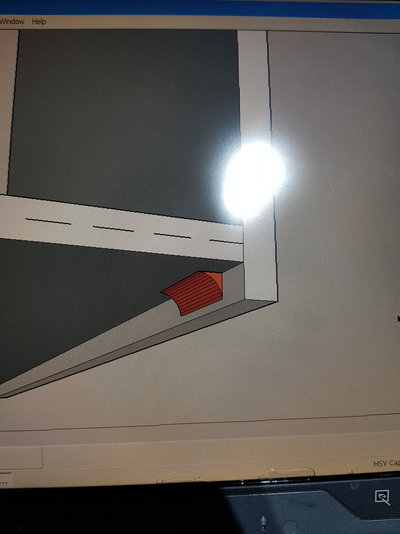

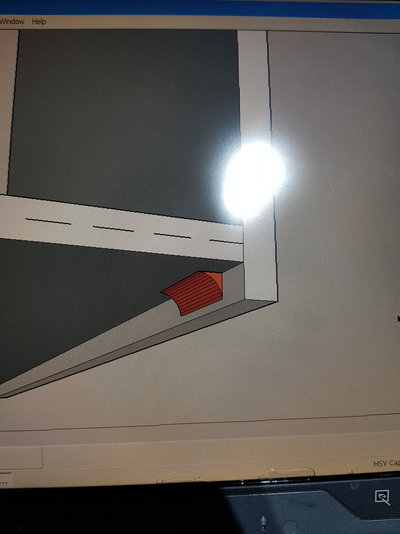

Or cut holes for the tabs so they slot through and leave a overhang for a fillet.

Option 1 looks like the best bet to me although the sheets are over a meter long and trying to hold them within 1mm over that distance might be a challenge but I am thinking I can put tacks on all the tabs then weld the joint runs up.

Option 3 might be the easiest way to hold everything in place but i am concerned i will end up with a distorted edge on the stick out unless i clamp a backing bar to that as well somehow.

Any tips?

Planning to use pulse mig,

Normally I would set it up inside corner to inside corner so I have 2x 2mm faces to weld against.

In this case I would like some location tabs/slots cut into the sheets which rules out corner to corner setup.

So I have a few options,

Recess the slots for the tabs by 1mm so I am left with a 1mm face to weld against a 2mm face (red=weld bead)

Recess the slots by 2mm and run along the face

Or cut holes for the tabs so they slot through and leave a overhang for a fillet.

Option 1 looks like the best bet to me although the sheets are over a meter long and trying to hold them within 1mm over that distance might be a challenge but I am thinking I can put tacks on all the tabs then weld the joint runs up.

Option 3 might be the easiest way to hold everything in place but i am concerned i will end up with a distorted edge on the stick out unless i clamp a backing bar to that as well somehow.

Any tips?